Digital printing machine conduction band cleaning processing device

A digital printing machine and cleaning technology, applied in printing devices, printing machines, general parts of printing machinery, etc., can solve problems such as unfavorable work efficiency, troublesome operation, affecting use, etc., to achieve good promotion and utilization value and ensure printing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the embodiments of the present invention with reference to the accompanying drawings, and the embodiments do not constitute a limitation to the present invention:

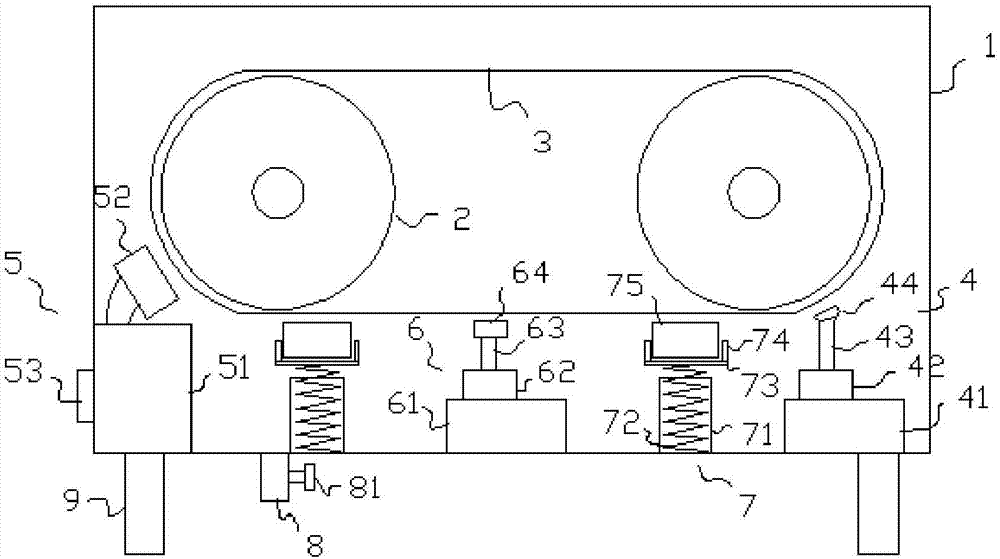

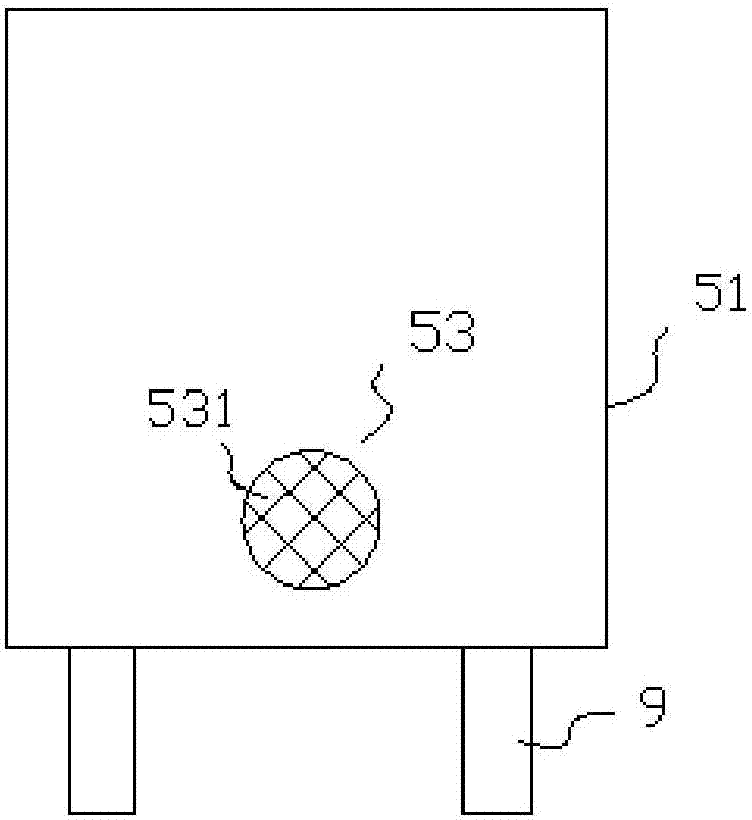

[0024] Such as figure 1 , figure 2 As shown, the cleaning and processing device for the guide belt of the digital printing machine has a structure including a chassis 1 and a bottom leg 9. The chassis 1 is provided with a guide roller 2, and the guide roller 2 is provided with a guide belt 3. The bottom right end of the chassis 1 under the guide belt 3 is provided with a cleaning agent spraying device 4, the left end of the bottom surface of the chassis 1 is provided with a drying device 5, the middle of the bottom surface of the chassis 1 is provided with a clean water spraying device 6, and the left and right sides of the clean water spraying device 6 There are scrubbing devices 7 on both sides. When in use, the device can be processed sequentially from right to left at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com