A lift with a separate lifting device and its working method

The technology of a lifting device and working method, applied in the field of lifts, can solve the problems of being unable to correspond to different types of cars of different sizes at the same time, the single function of the lift, and the single model of the lift, etc., and achieve strong grip , The use process is intelligent, and the effect of ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

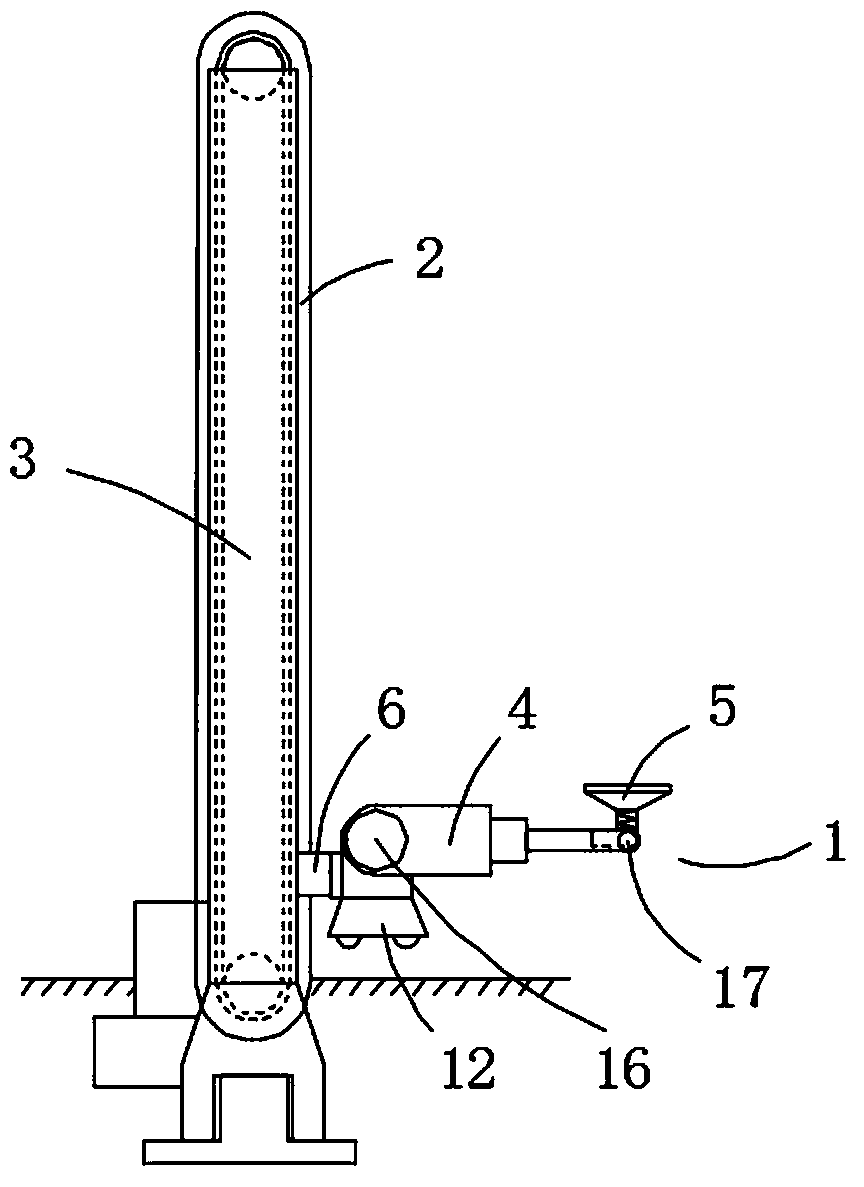

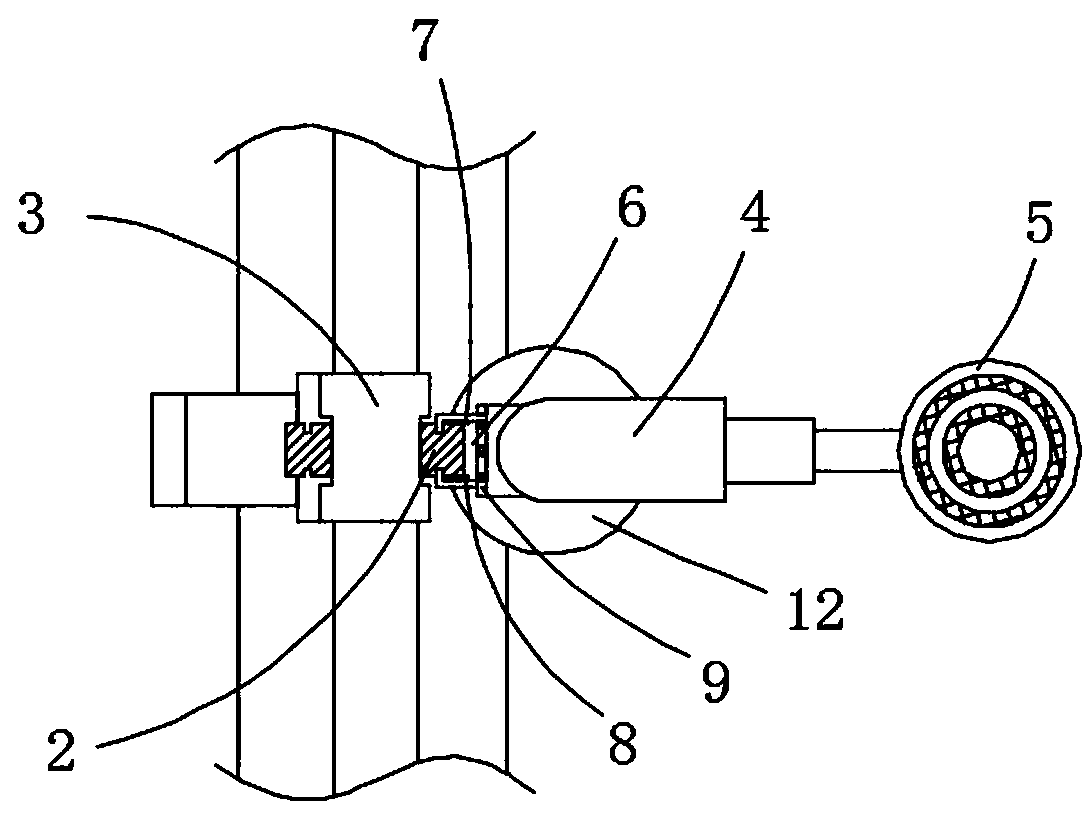

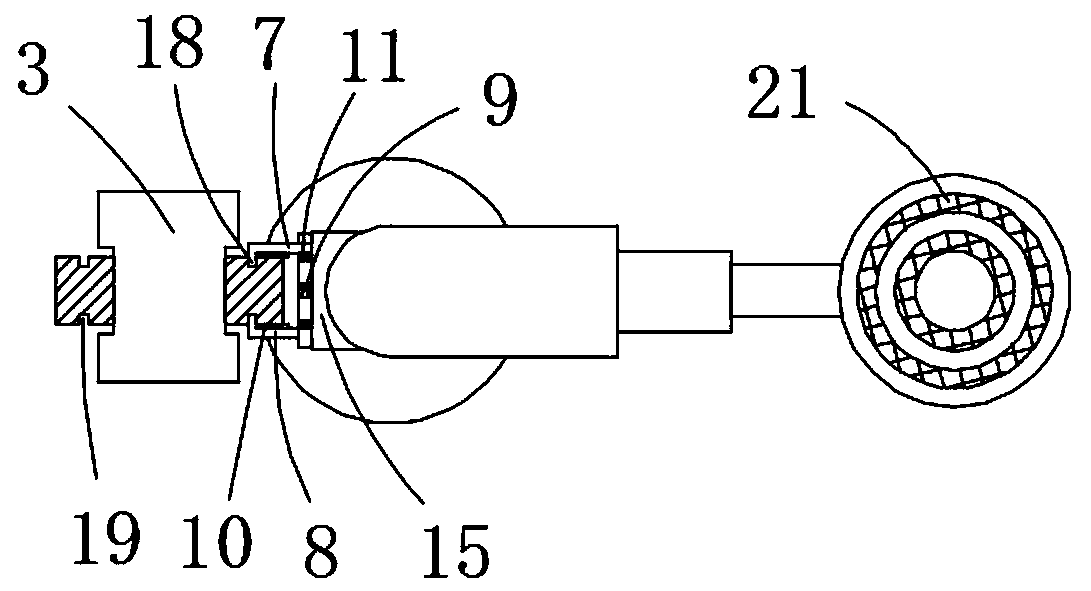

[0030] A kind of lifting machine with separate lifting device of the present invention, such as Figure 1 to Figure 6 As shown, it includes a group of lifting devices 1 working independently, and a group of columns 3 provided with a first lifting system 2, wherein the lifting device 1 includes an independent control module, a second lifting system 4, a grabbing device 5 and The docking device 6; the docking device 6 is connected or separated from the mobile pair of the first lifting system 2 through the control of the control module; the docking device 6 includes a set of oppositely arranged first clamping arms 7 and second clamping arms 8, A clamp arm driving device 9 that drives the opening and closing of the first clamp arm 7 and the second clamp arm 8 is connected with the control module. The ends of the first clamp arm 7 and the second clamp arm 8 are respectively provided with friction plates 10, and the first clamp arm 7 and the second clamp arm 8 clamp the moving pair ...

Embodiment 2

[0049] Such as Figure 7 As shown, the ends of the first clamping arm 7 and the second clamping arm 8 are respectively provided with an electromagnetic device 25, and the electromagnetic device 25 is connected to the control module; the first clamping arm 7 and the second clamping arm 8 clamp and move up and down pair, the moving pair is a chain transmission system, including a transmission chain and a sprocket, and the transmission chain is a moving pair. This structure has stable transmission, reliable structure, strong bearing capacity and flexible lifting; the grabbing device 5 is an air-pumping suction cup device.

[0050] It also includes a remote control system connected to each lifting device 1, the remote control system is respectively connected with the control module of each lifting device 1, and is provided with an operation interface to perform independent or combined operations on all lifting devices 1. manipulation.

[0051] Other structures are the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com