Flexible bottom blowing device for precision casting pouring

A technology of precision casting and air blowing device, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve problems such as troubles, and achieve the effect of fast operation, good compactness and strong correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

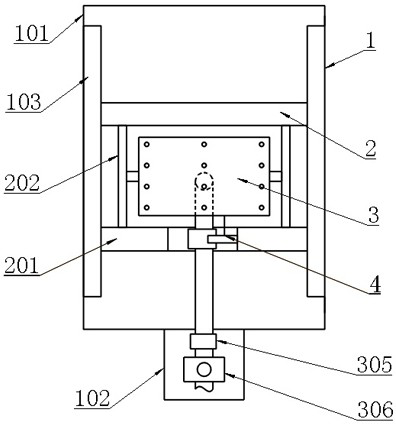

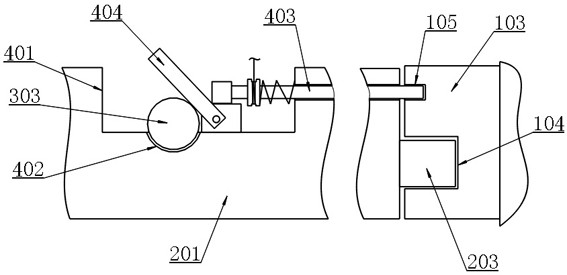

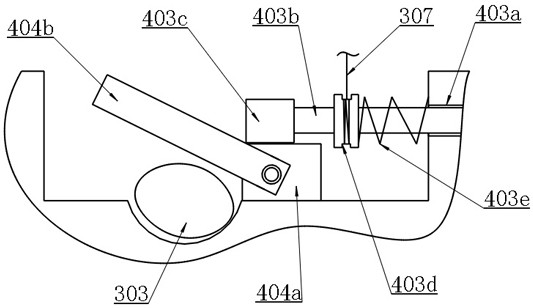

[0026] Example: as attached Figure 1-5 As shown, a flexible bottom air blowing device for precision casting pouring includes an installation groove unit 1 arranged on the ground, a sliding frame body unit 2 arranged on the installation groove unit 1, and a sliding frame body unit 2 arranged on the sliding frame Body unit 2 and the rotary blowing plate unit 3 connected to the air pump, and the blowing pipeline that is arranged on the sliding frame body unit 2 and used to close the rotary blowing plate unit 3, or in the installation The opening indicating plate unit 4 of the sliding frame body unit 2 is inserted and fixed on the slot unit 1 .

[0027] In this embodiment, the mold is placed directly above the installation groove unit 1, and then the sliding frame body unit 2 slides to a suitable position in the installation groove unit 1, that is, under the mold, and then the rotary blowing The plate unit 3 is rotated to an appropriate angle on the sliding frame body unit 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com