Monoazo compound, preparation method and use thereof

A compound and monoazo technology, applied in the field of monoazo compounds, can solve the problems of not being excellent enough and the washing fastness of polyester and ammonia fabrics are not ideal, and achieve good dyeing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

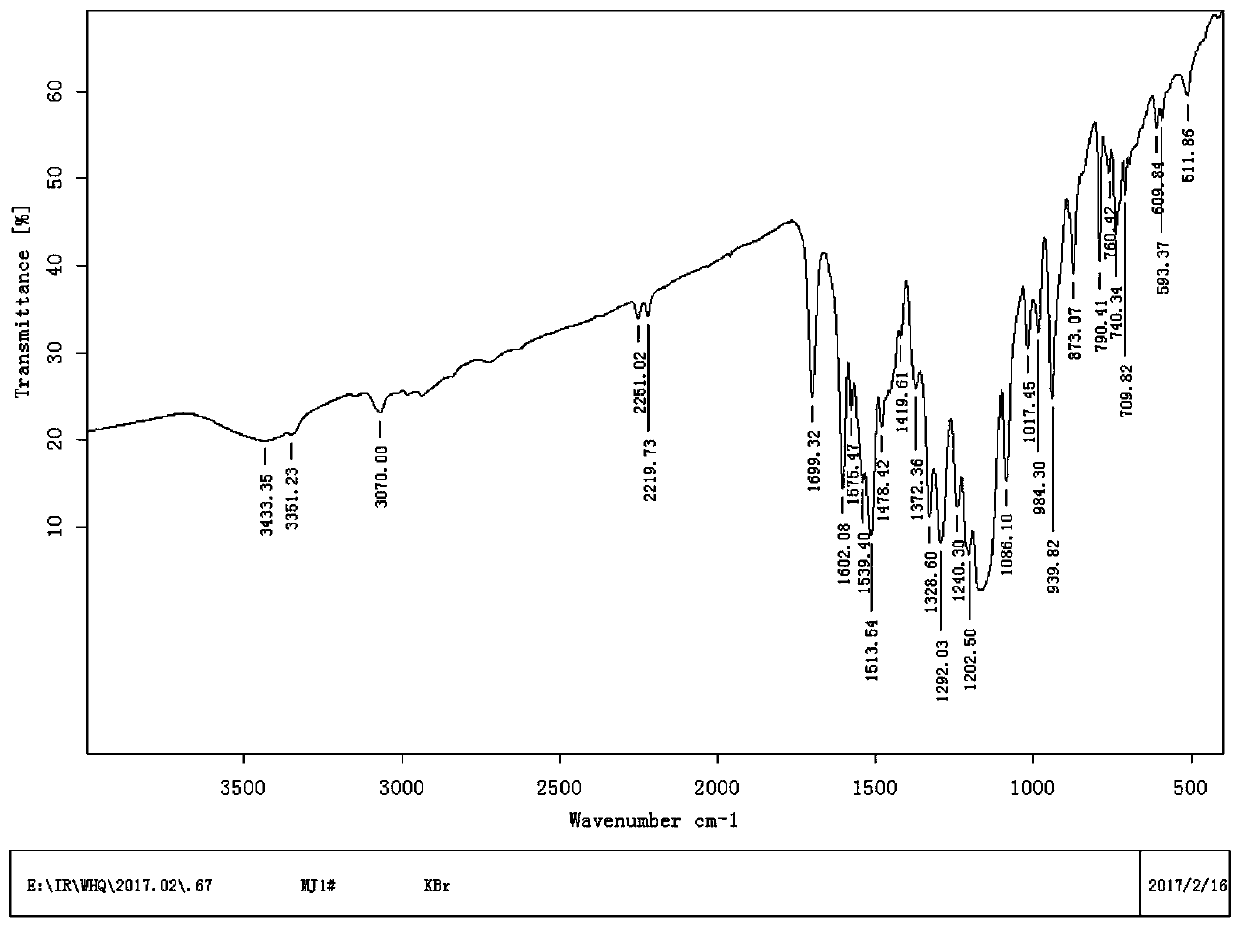

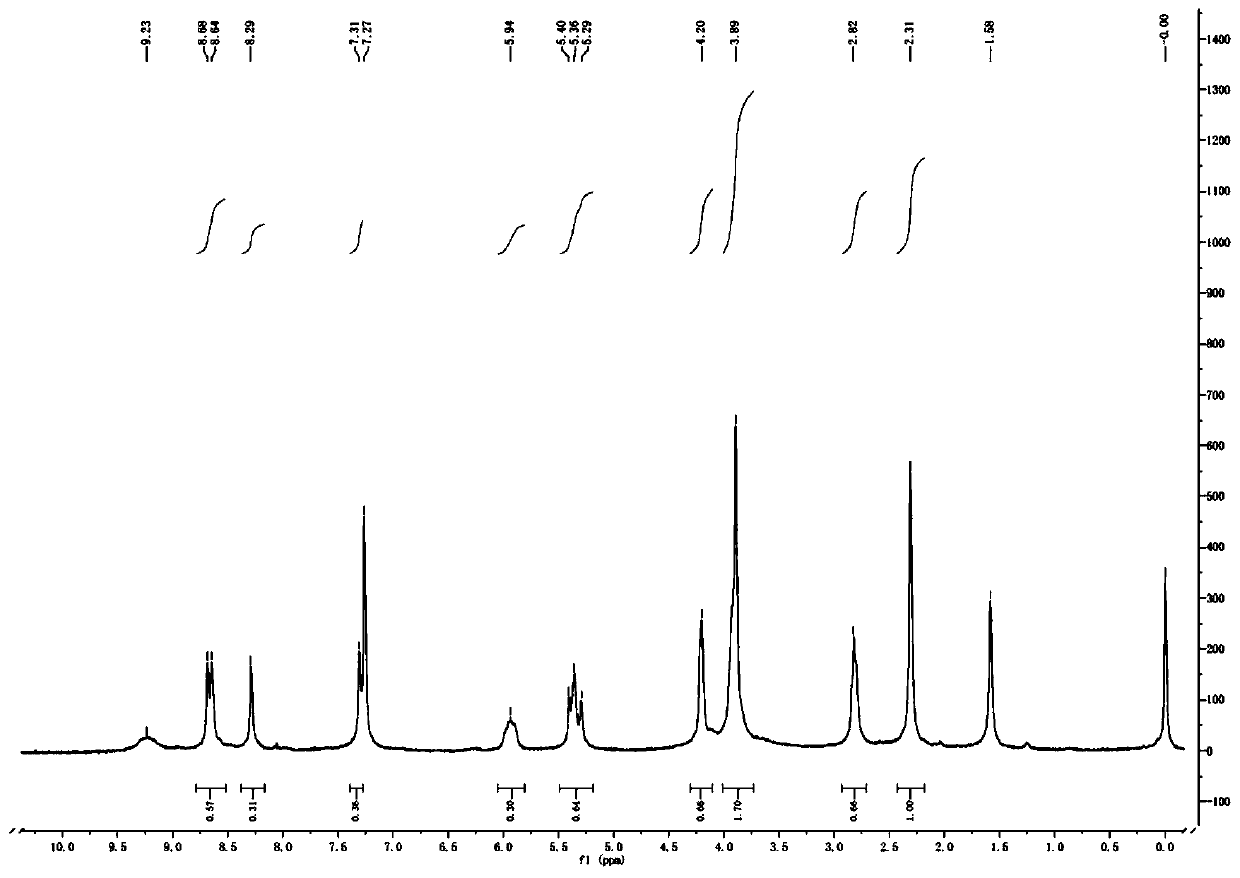

Image

Examples

Embodiment 1

[0045] (1) Synthesis of coupling solution

[0046] 1. Cyanoethylation

[0047] Into a 250 ml flask were added 56 g of 3-amino-4-methoxyacetanilide, 90 g of water, 1.8 g of 30% hydrochloric acid and 20 g of acrylonitrile.

[0048] Slowly heat up with stirring. Control the temperature at 80-90°C and keep it warm for 46 hours.

[0049] Underpressure distillation reclaims excessive acrylonitrile, obtains the compound shown in formula (IV) in the material,

[0050]

[0051] 2. Allylation

[0052] Add 28 grams of allyl chloride to the above material below 50-60°C.

[0053] Slowly heat up while stirring, control the temperature at 80-90°C and keep it warm for 24 hours.

[0054] Excess chloropropene was recovered by distillation under reduced pressure.

[0055] The output is bottled, weighed, and the obtained coupling liquid is set aside. Obtain the compound shown in formula (V) in the coupled compound,

[0056]

[0057] (2) The synthesis of the parent body

[0058] Wei...

Embodiment 2

[0089] Put 66.0ml of sulfuric acid (98%) into the flask, add 52.4g of 2,4-dinitro-6-bromoaniline under controlled room temperature, continue to stir for 3 minutes, cool with an ice bath to reach 20-30°C, the temperature 68.0 g of 42% nitrosyl sulfuric acid was dropped into the reaction mixture, and stirring was continued at this temperature for 4 hours. After completing the reaction, the mixture was dropped into a mixture of 30ml sulfuric acid (98%), 900.0g ice water and 49g of the compound shown in the following formula (VII) within 30 minutes at 0-5°C,

[0090]

[0091] Stirring was continued for 2 hours, then 1000ml of water was added, and the temperature was slowly raised to 60° C. over 1 hour and kept at this temperature for 1 hour. The resulting suspension was suction filtered, washed with water and dried to obtain the compound represented by the following formula (VIII):

[0092]

[0093] Stir and mix 52 g of the dry product of the compound represented by the abo...

Embodiment 3-9

[0111] The method provided in Example 2 or Example 3 was used to synthesize the monoazo compound with the structure of Example 3-9, and the results are shown in Table 5.

[0112] The monoazo compound synthesized by the embodiment 3-9 of table 5

[0113] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com