Control method for room-temperature and high-temperature mechanical properties of ZG15CR2Mo1 material

A zg15cr2mo1, high-temperature mechanics technology, applied in manufacturing tools, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as fluctuations in mechanical properties at room temperature and high temperature, affecting stable control of product quality, and difficulty in meeting production and use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

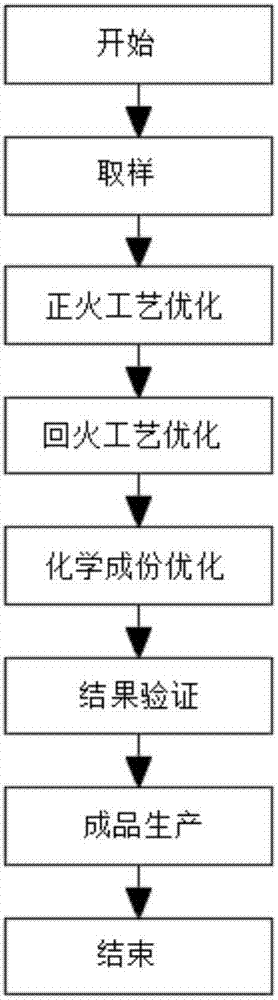

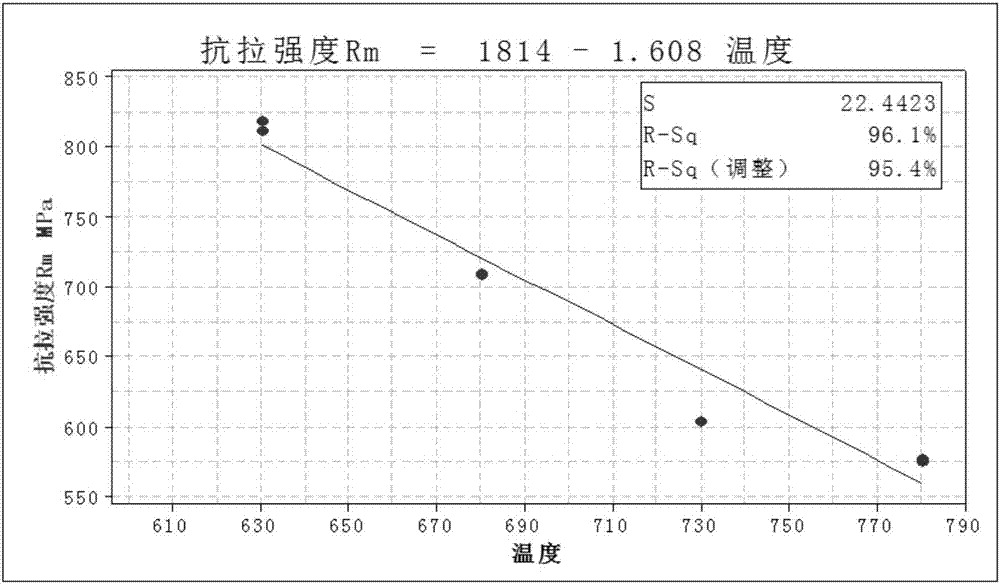

[0029] Example 1, such as Figure 1-6 Shown:

[0030] The purpose of the present invention is just to: aim at the above-mentioned problem existing at present, the present invention carries out careful in-depth research to ZG15Cr2Mo1 material physical properties, phase change point, CCT curve, by formulating different heat treatment processes, detects and analyzes material characteristic, optimizes heat treatment process, Study the influence of chemical composition on performance, optimize chemical composition control and other methods, and formulate a heat treatment process and chemical composition control method that meet the mechanical properties of ZG15Cr2Mo1 material at room temperature and high temperature, so as to meet the needs of stable control of mechanical properties of ZG15Cr2Mo1 material, so as to solve the existing problems. There are deficiencies and flaws in the technology.

[0031] In order to achieve the above object, the technical solution adopted in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com