a cage roll

A technology of rotating rollers and roller sleeves, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of affecting the formation of aluminum foil tunnel holes, reducing the quality of corroded foil products, and not meeting production requirements, etc., and achieves simple structure, high practicability, and guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

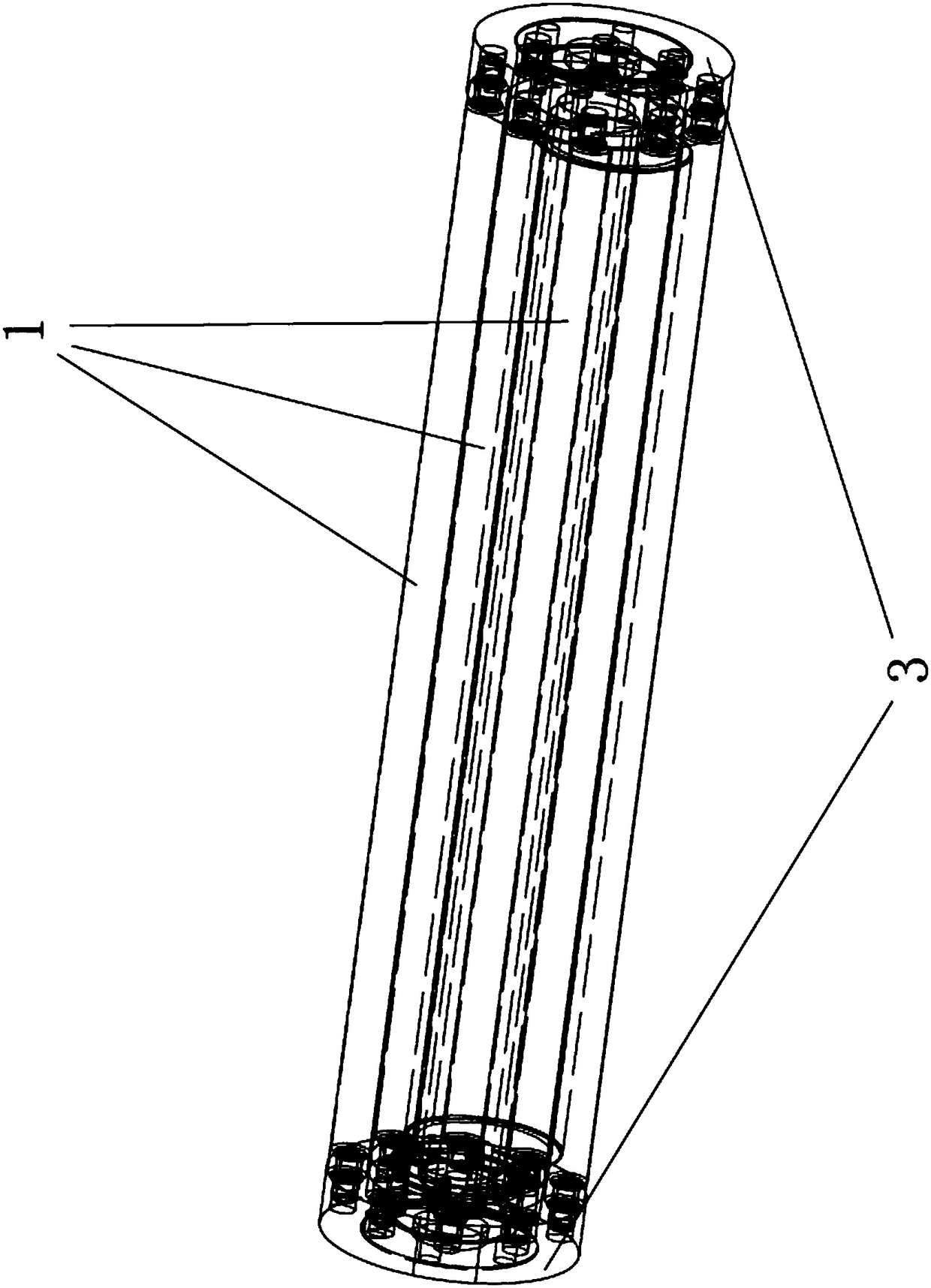

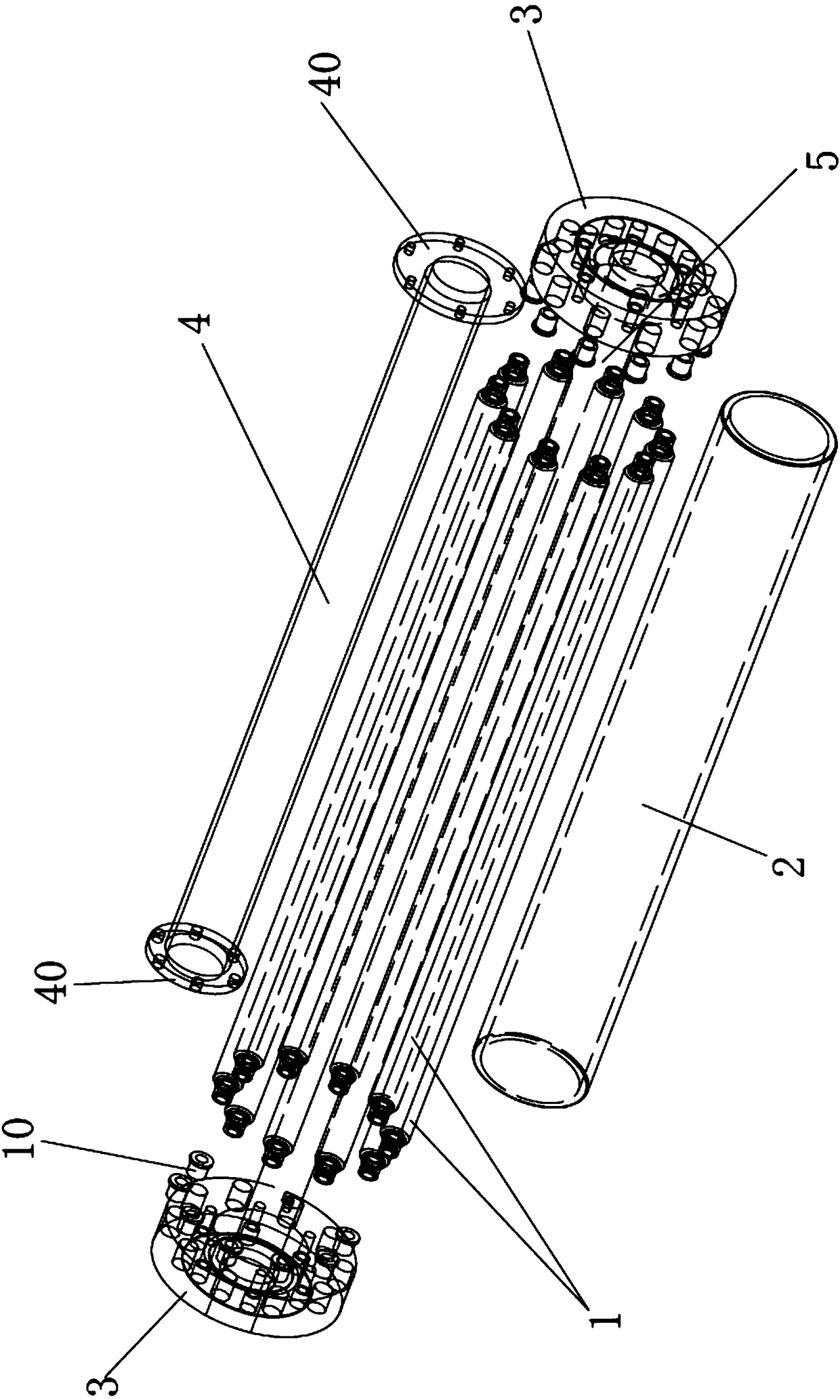

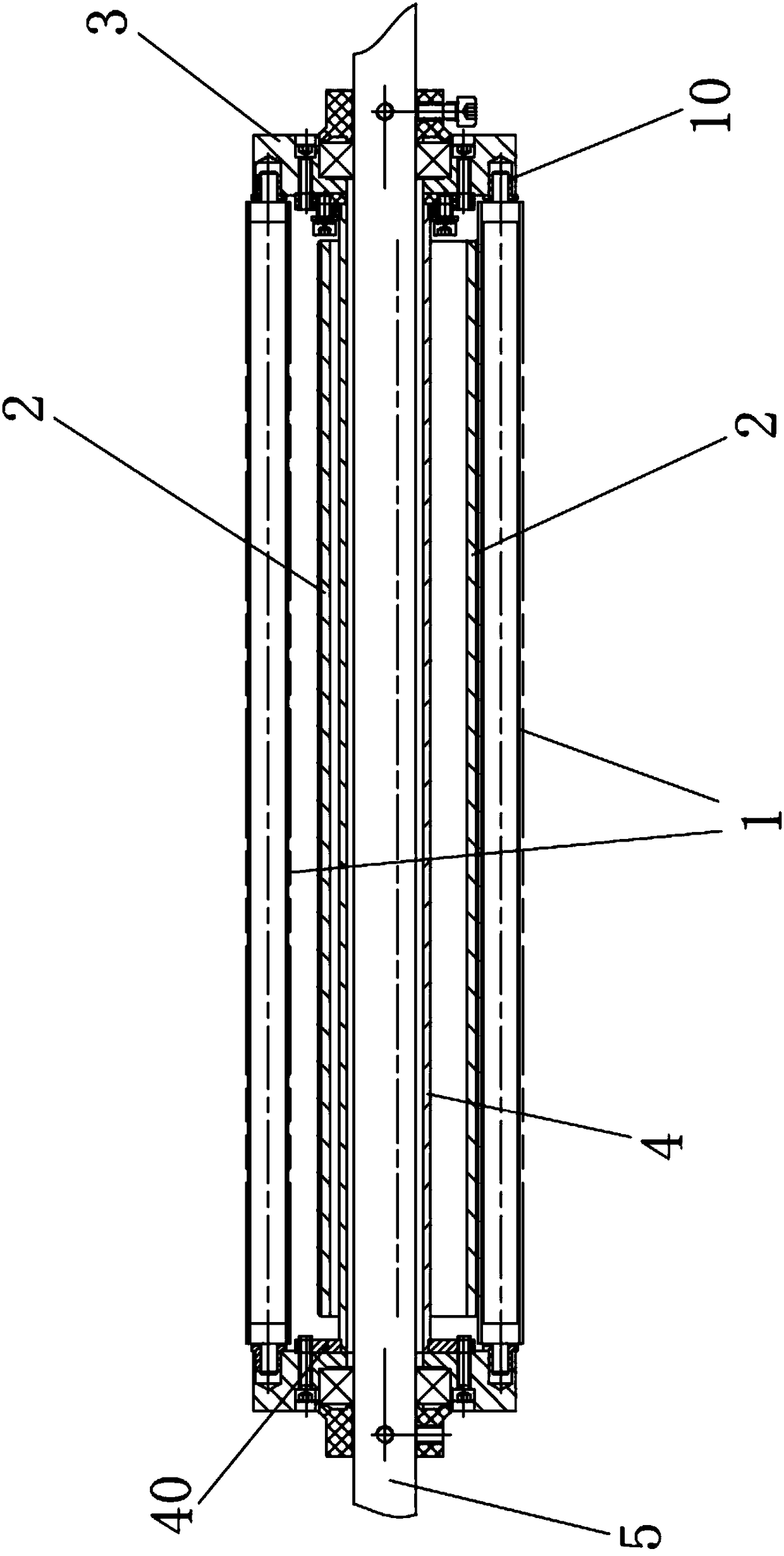

[0022] Please also see Figure 1-3 , figure 1 It is the structural representation of the cage roll of the present invention, figure 2 It is a structural exploded view of the cage roll of the present invention, image 3 It is a cross-sectional view of the cage roll of the present invention.

[0023] The cage roller provided by the present invention includes a plurality of rotating rollers 1 , a threaded pipe 2 , two disks 3 , a flanged pipe 4 and a total rotating shaft 5 . The plurality of rotating rollers 1 are parallel to the threaded pipe 2 and surround the threaded pipe 2 , and the two ends of each rotating roller 1 are respectively connected with the two discs 3 . The threaded pipe 2 can move in the space formed by the plurality of rotating rollers 1 and the two discs 3, and the surface is provided with threads. Both ends of the flange pipe 4 are respectively fixedly connected with the two discs 3 , and the threaded pipe 2 is sleeved outside the flange pipe 4 . The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com