Offshore wind power project steel pile foundation and construction method thereof

A technology of offshore wind power and engineering steel, applied in infrastructure engineering, construction, etc., can solve the problems of large diameter, low construction efficiency, and difficult construction, and achieve the reduction of diameter and length, reduce construction cost, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

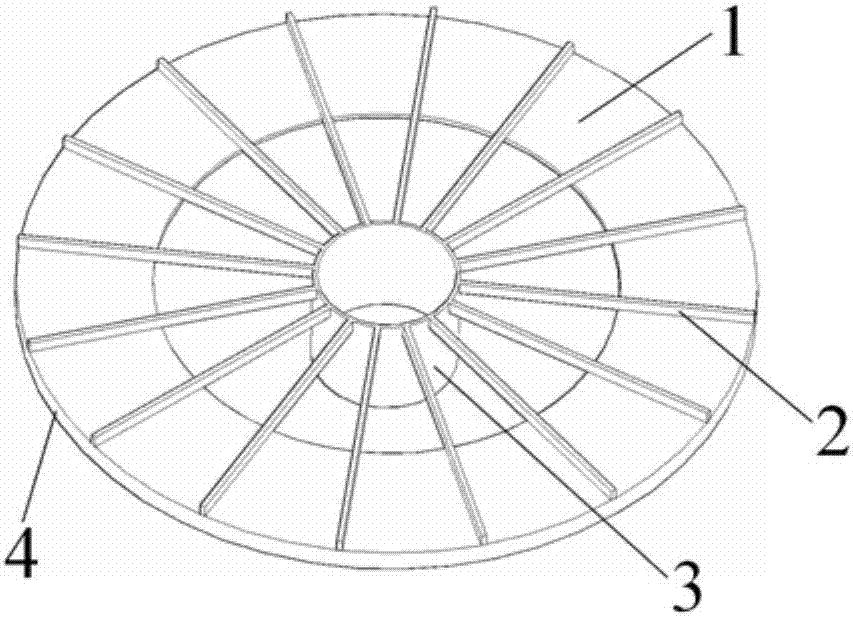

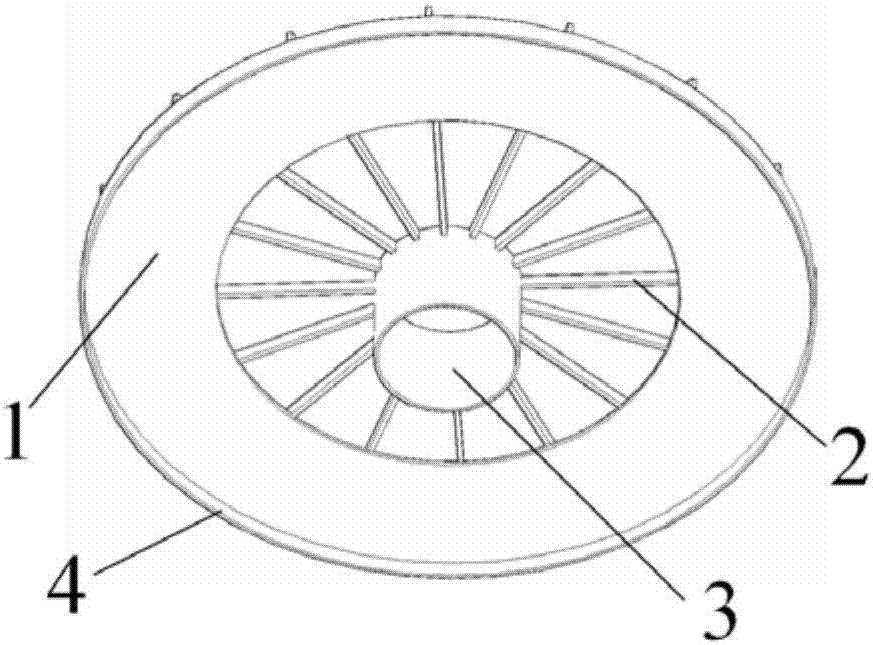

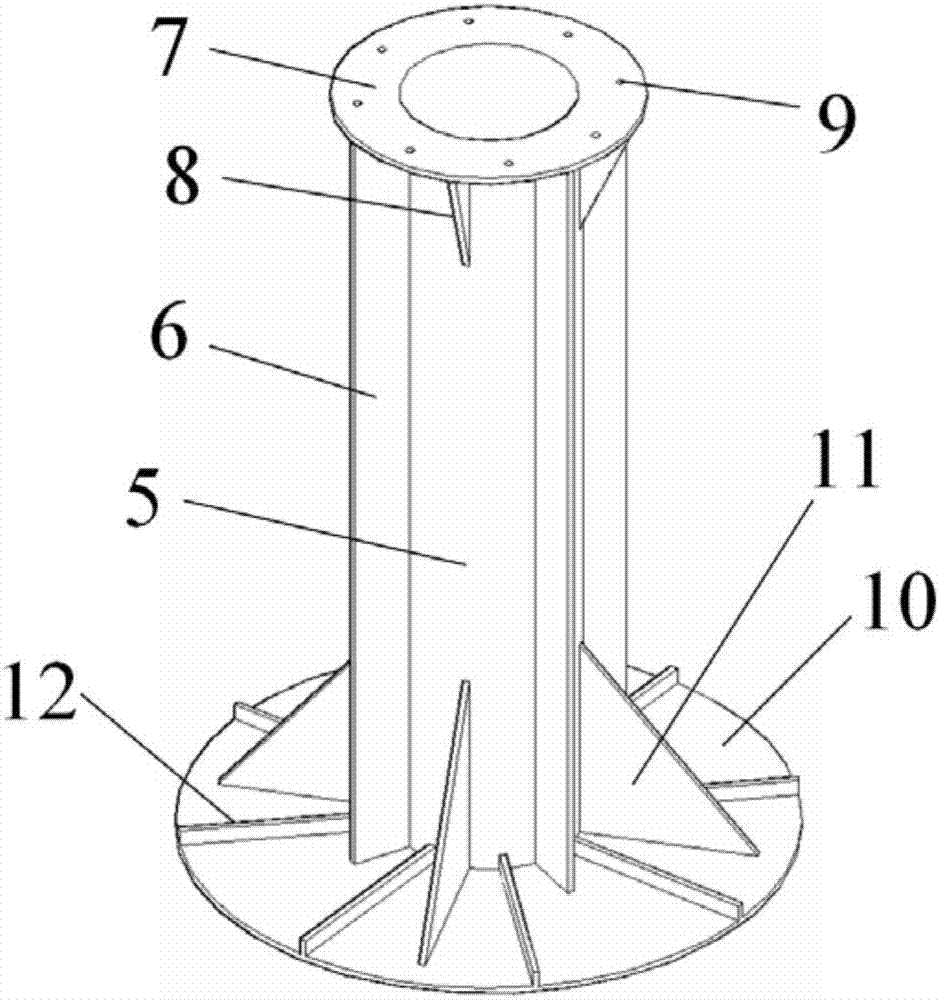

[0051] See attached picture:

[0052] A steel pile foundation for an offshore wind power project, including a central steel pile 16 driven into a designated sea area. The central steel pile 16 is sequentially fitted with a bottom support and a sleeve outside the pile. The bottom support slides down along the central steel pile 16 and touches the seabed. The lower end of the pile outer sleeve presses the bottom bracket, and the upper end of the pile outer sleeve is connected with a fan tower 17 .

[0053] The pile outer sleeve is composed of a bottom sleeve 5, multiple middle sleeves 13, and a top sleeve 14 based on bolts 15. The assembled pile outer sleeve covers the central steel pile 16 and sinks into the seabed to press on the bottom support. The wind turbine tower 17 is connected to the top sleeve 14 on the ring disk 1 of the wind turbine. The gravity of the wind turbine is directly transmitted to the seabed based on the outer sleeve of the pile. The horizontal load on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com