Surface defect detection device used for steel ball continuous production

A defect detection and steel ball technology, which is used in measuring devices, optical testing of flaws/defects, and material analysis by optical means, which can solve the problems of quality error, insufficient inspection accuracy, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

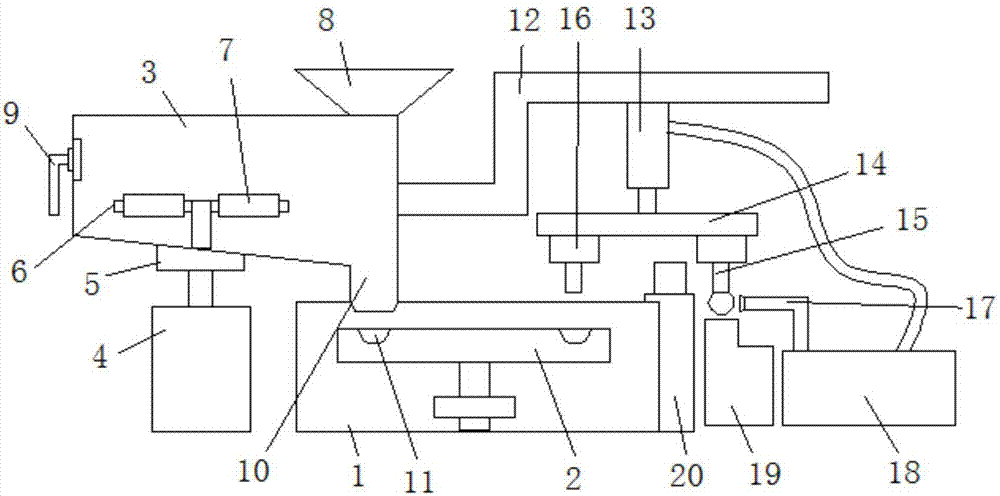

[0009] Referring to the accompanying drawings, a surface defect detection device for continuous production of steel balls includes a base 1, a rotating disk 2 is arranged in the base 1, a lowering box 3 is arranged above the left end of the base 1, and the lowering box is The bottom of 3 is provided with a support seat 4, and a turntable 5 is arranged on the support seat 4. The upper end of the turntable 5 is connected with a stirring rod 6. The side wall of the stirring rod 6 is provided with a sponge pad 7. The top of the box 3 is provided with a feeding port 8 , the side wall of the unloading box 3 is provided with a drying air duct 9 , and a discharge pipe 10 is arranged below the unloading box 3 , and below the discharge pipe 10 Align the turntable 5, the surface of the turntable 2 is provided with a limit groove 11, the side wall of the unloading box 3 is provided with a bracket 12, and a cylinder 13 is fixedly installed on the bracket 12, and the piston of the cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com