Fingerprint module manufacturing method and fingerprint module

A technology of fingerprint module and manufacturing method, which is applied in the direction of acquiring/arranging fingerprints/palmprints, character and pattern recognition, instruments, etc., and can solve the problem of fixed and immutable colors of the user interface of fingerprint recognition chips, and achieve the effect of improving the degree of recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

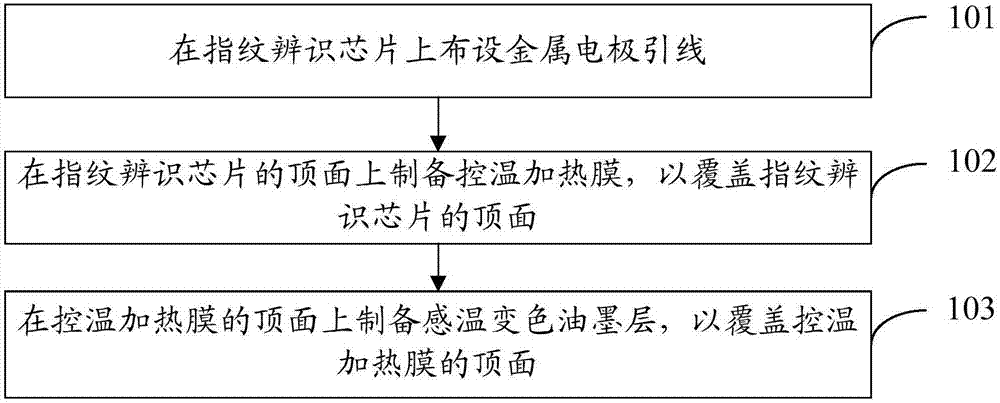

[0020] refer to figure 1 , shows a flow chart of steps of a method for manufacturing a fingerprint module according to Embodiment 1 of the present invention.

[0021] The fingerprint module manufacturing method of the embodiment of the present invention comprises the following steps:

[0022] Step 101: Arranging metal electrode leads on the fingerprint recognition chip.

[0023] One end of the metal electrode lead is arranged on the top surface of the fingerprint identification chip, and the other end of the metal electrode lead is connected with the welding pin on the bottom surface of the fingerprint chip. The metal electrode mainly plays the function of electrical signal conduction, and provides heating current for the temperature-controlled heating film.

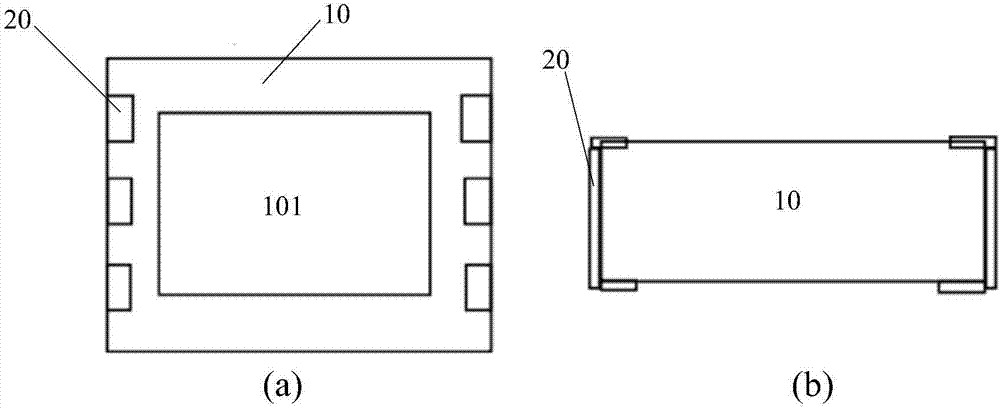

[0024] Among them, the front schematic diagram of the fingerprint identification chip after the metal electrode leads are laid out is as follows: figure 2 As shown in (a), the side schematic diagram is as follows f...

Embodiment 2

[0039] refer to Figure 6 , shows a flow chart of steps of a method for making a fingerprint module according to Embodiment 2 of the present invention.

[0040] The fingerprint module manufacturing method of the embodiment of the present invention specifically includes the following steps:

[0041] Step 201: Arranging metal electrode leads on the fingerprint recognition chip.

[0042] Wherein, one end of the metal electrode lead is arranged on the top surface of the fingerprint identification chip, and the other end of the metal electrode lead is connected with the welding pin on the bottom surface of the fingerprint chip.

[0043]Specifically, metal electrode leads can be arranged on the fingerprint identification chip by any one of electroplating, metal printing and vacuum sputtering to prepare a thin film.

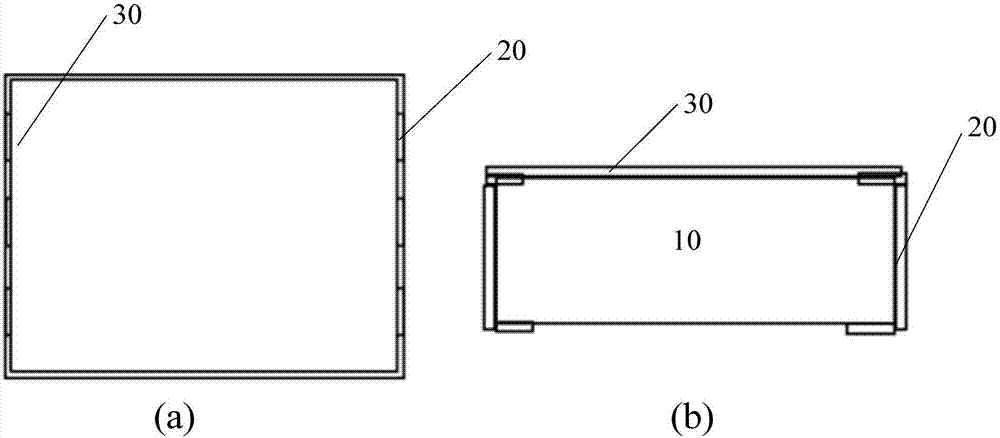

[0044] Step 202: Prepare a temperature-controlled heating film on the top surface of the fingerprint identification chip to cover the top surface of the fingerprint i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com