Eccentricity-adjustment-free die device for multi-core cable insulation extrusion and extrusion manufacturing technology

A technology for multi-core cables and moulds, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, and circuits. It can solve the problems of poor uniformity of cable insulation thickness, excessive cable insulation thickness, and difficulty in producing cable products. , to achieve the effect of avoiding unqualified products, reducing the waste of insulating materials and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

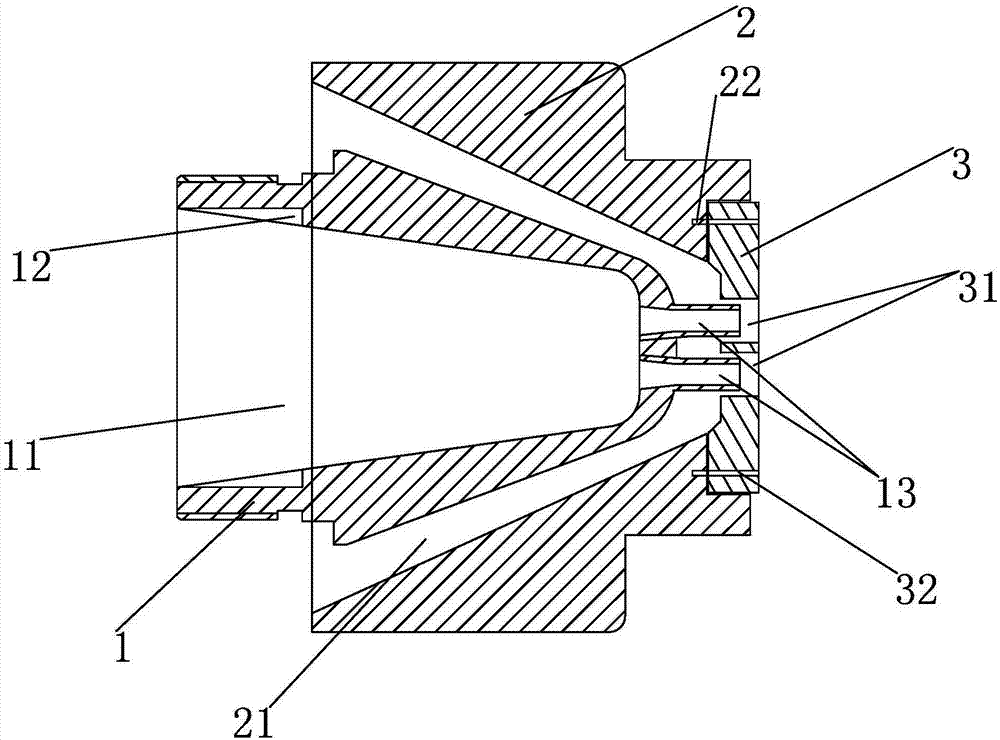

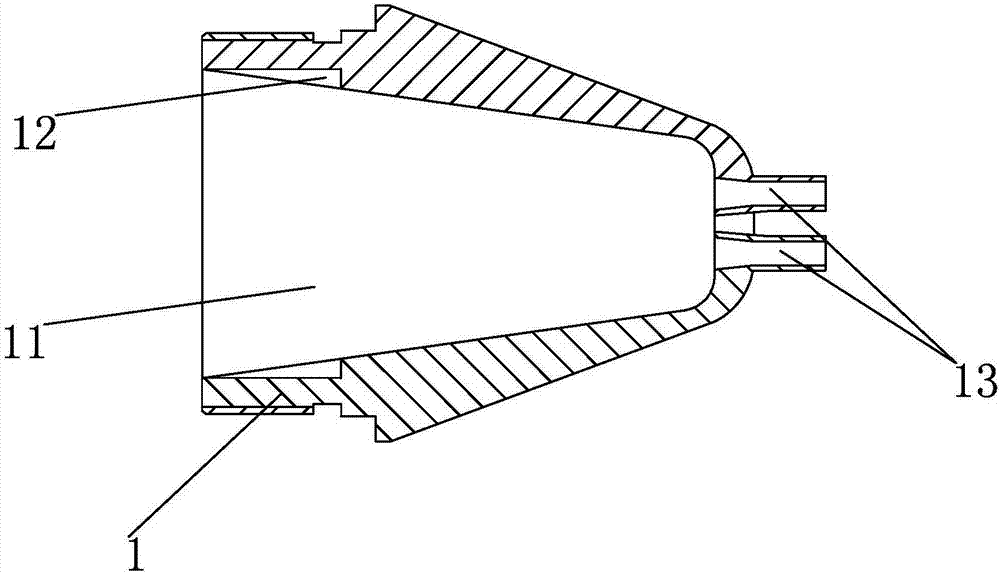

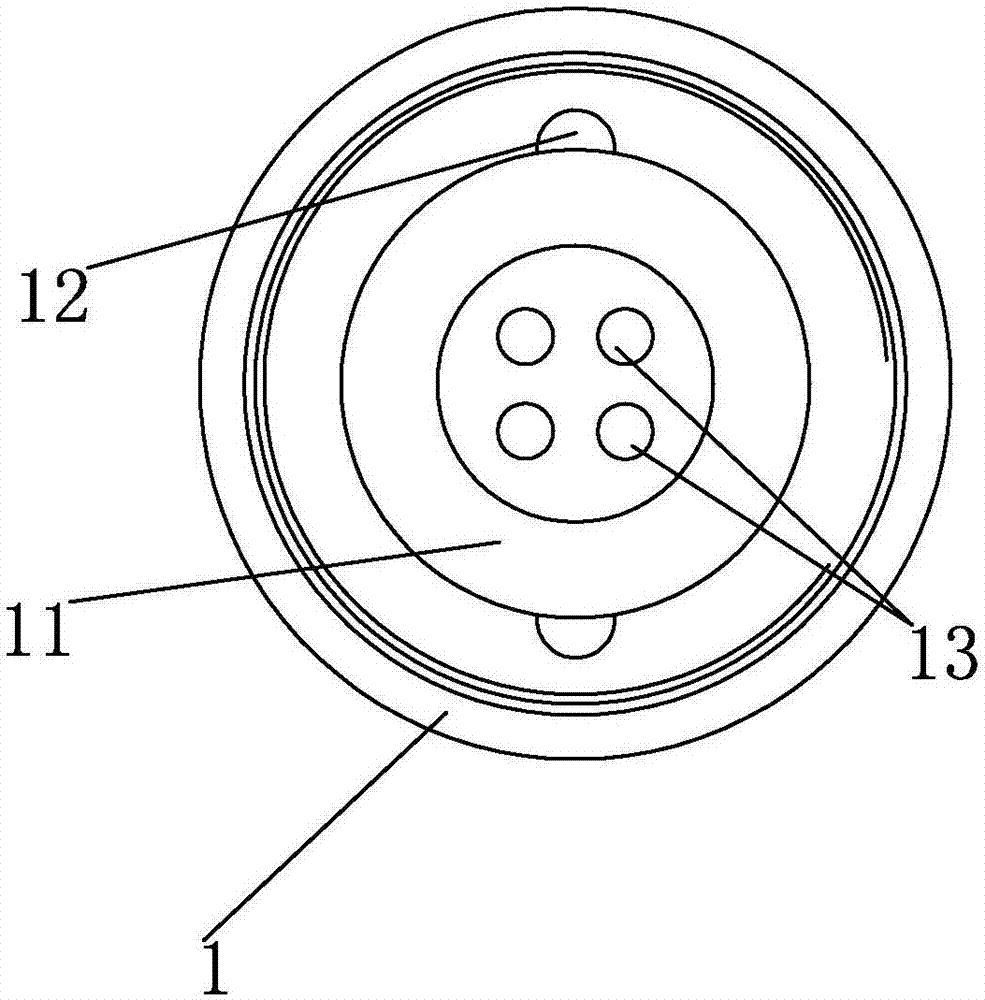

[0052] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0053] Such as figure 1As shown, the non-adjustable eccentric mold device for multi-core cable insulation extrusion in this embodiment includes a porous mold core 1, a mold sleeve 2 is placed outside the porous mold core 1, and the inner wall of the mold sleeve 2 is in contact with the porous mold. A gap is formed between the outer wall surfaces of the core 1; the front end of the porous core 1 is conical, and a core cavity 11 which is radially reduced towards the front end is arranged at the rear end of the core, and one end of the core cavity 11 faces Outward extension, and a plurality of mold core nozzles 13 are opened in the extension part; the end of the mold sleeve seat 2 is provided with a ring hole, and the mold sleeve plate 3 matched with it is installed at the ring hole, and the mold sleeve plate 3 is provided with A plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap