Chip batch positioning system

A positioning system and chip technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low chip efficiency and difficulty in mass production, and achieve the effect of improving work efficiency, ensuring accurate positioning, and facilitating shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

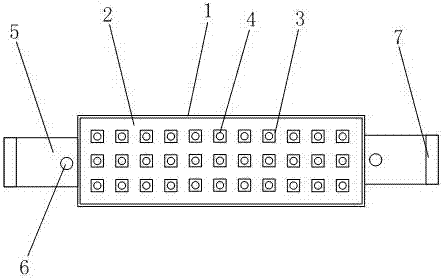

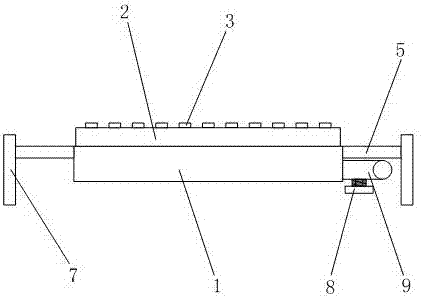

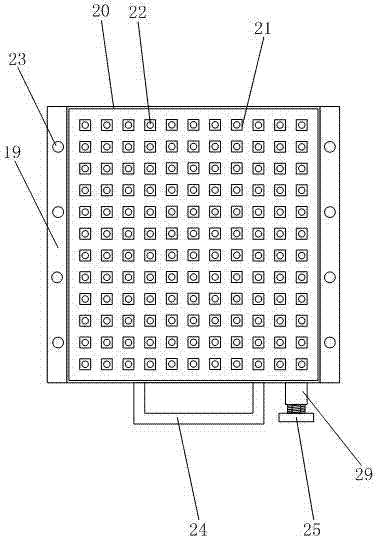

[0020] Such as Figure 1-6 As shown, a chip batch positioning system disclosed in the present invention includes: a suction board device, a suction pen device and an air source system.

[0021] Wherein, the suction plate device comprises a suction plate base 19, a rectangular frame 20 and a base air valve; the rectangular frame 20 is installed on the top of the suction plate base 19; 28; chip slots 21 are arranged in an array on the upper part of the suction plate base 19 and in the rectangular frame 20; chip air holes 22 are provided at the bottom of the chip slot 21; The base air cavity of the base; the left and right side edges of the suction plate base 19 tops are provided with positioning columns 23; the base air valve is installed on the side of the suction plate base 19 and communicates with the base air cavity; the pen suction device includes a strip plate 1 and Suction pen air valve; a boss 2 is provided on the upper part of the strip plate 1; a positioning bump 3 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com