Splitting type automatic mixing device of firework explosive

A mixing device, a separate technology, applied in mixers, transportation and packaging, chemical/physical processes, etc., can solve the problems of unavoidable safety accidents, large friction, etc., and achieve no safety hazards, uniform mixing, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

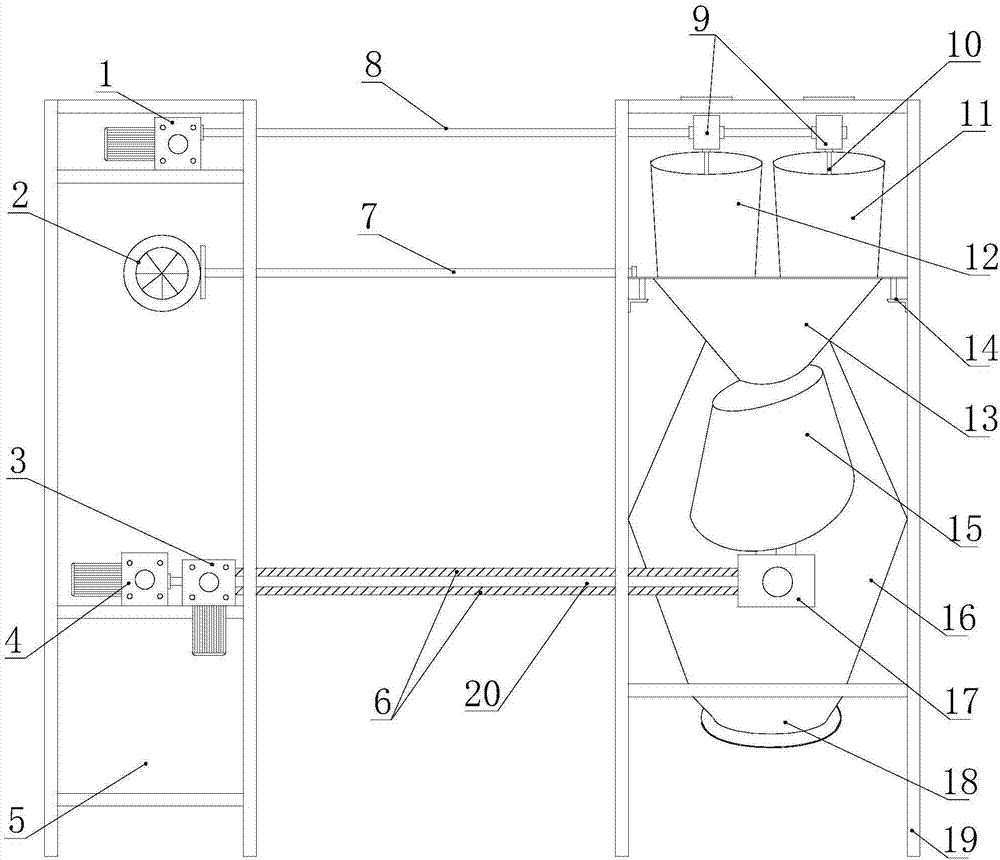

[0016] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the separate pyrotechnic drug automatic mixing device includes a primary screening and mixing mechanism and a secondary mixing mechanism arranged in the screening and mixing cabinet 19 from top to bottom in sequence.

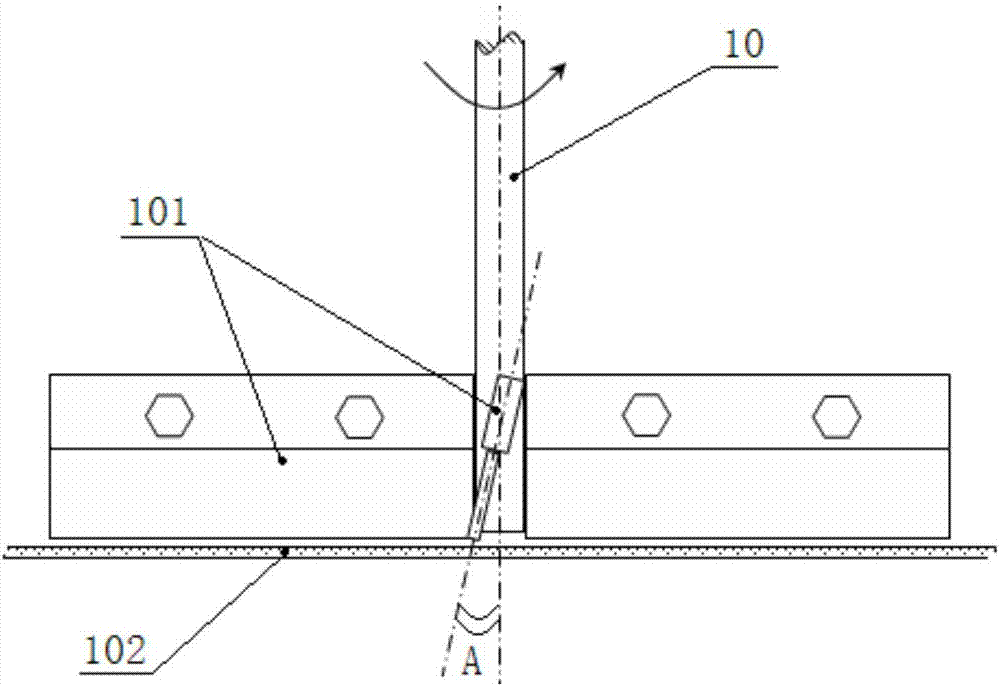

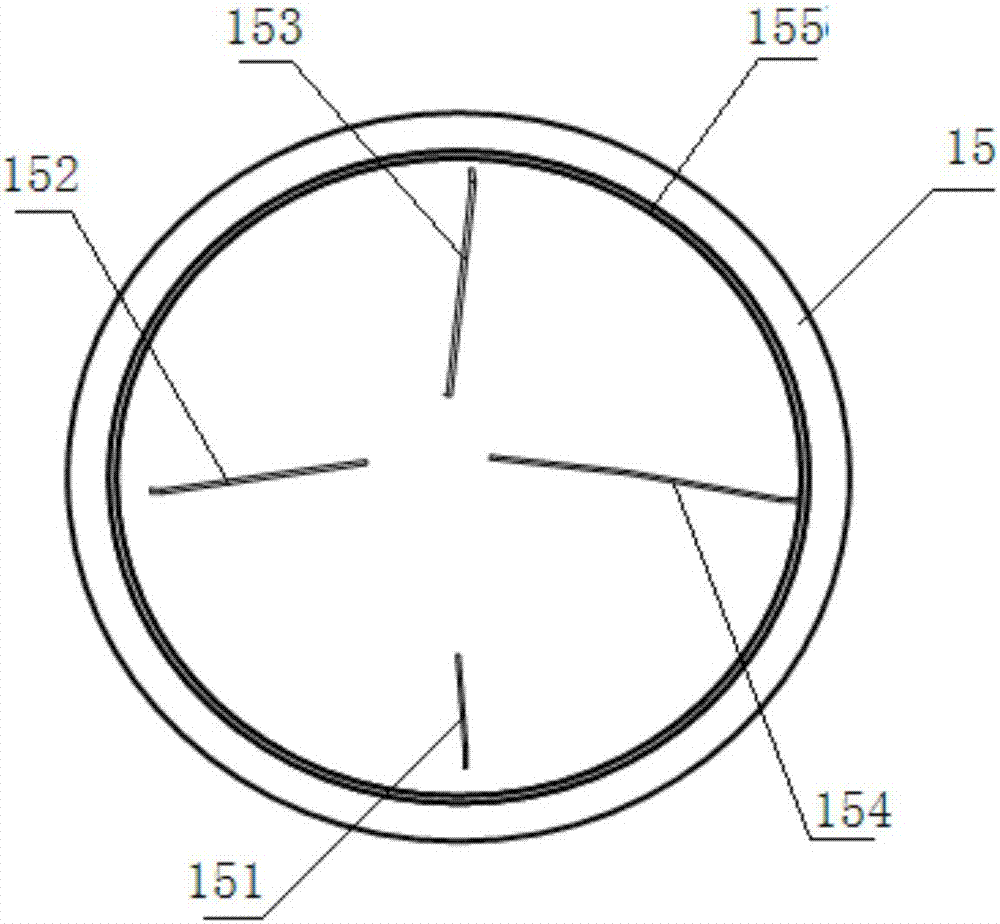

[0017] The primary screening mixing mechanism includes an oxidant screening mixing cylinder 11 and a screening mixing cylinder 12 for other components, and the oxidizing agent and other components of the pyrotechnic drug are screened separately to ensure safety. The structure of each sieve mixing cylinder is: the opening at the bottom end of the sieving mixing cylinder is closed by a screen 102, the sieving mixing cylinder is provided with a drug sieving device, and the drug sieving device includes a first rotary drive connected to the first rotary drive shaft 8. The rotating shaft 10 of the assembly 1 and the four spreading blades 101, the spreading blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com