A positioning device and method for flexible multi-point forming of wall panel parts

A multi-point forming and positioning device technology, which is applied to positioning devices, feeding devices, storage devices, etc., can solve problems such as cumbersome operations, achieve simple positioning, improve operation convenience and production efficiency, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

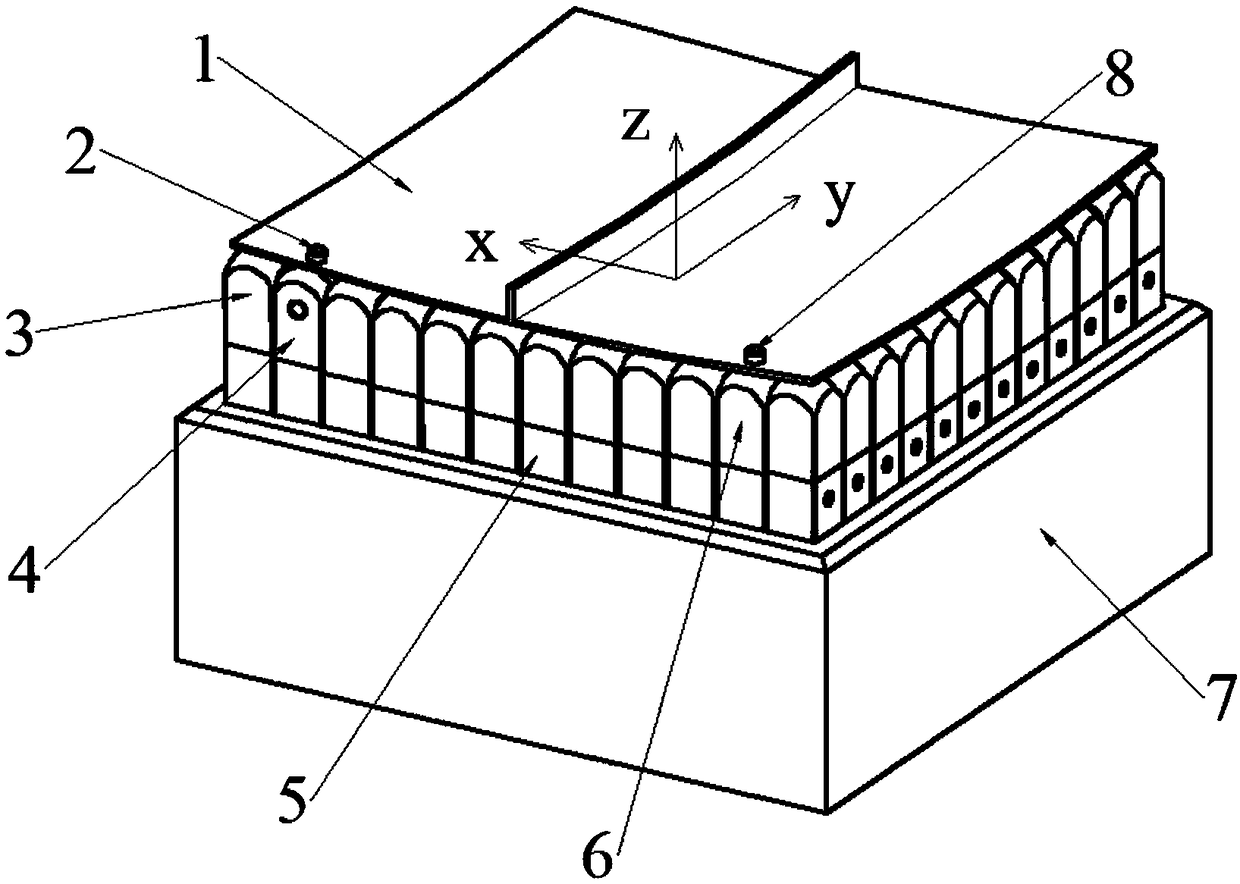

[0027] A positioning device for flexible multi-point forming of wall plate parts, the positioning device is composed of two parts: a fixed end constraining module 12 and a moving end constraining module 11. Specifically include:

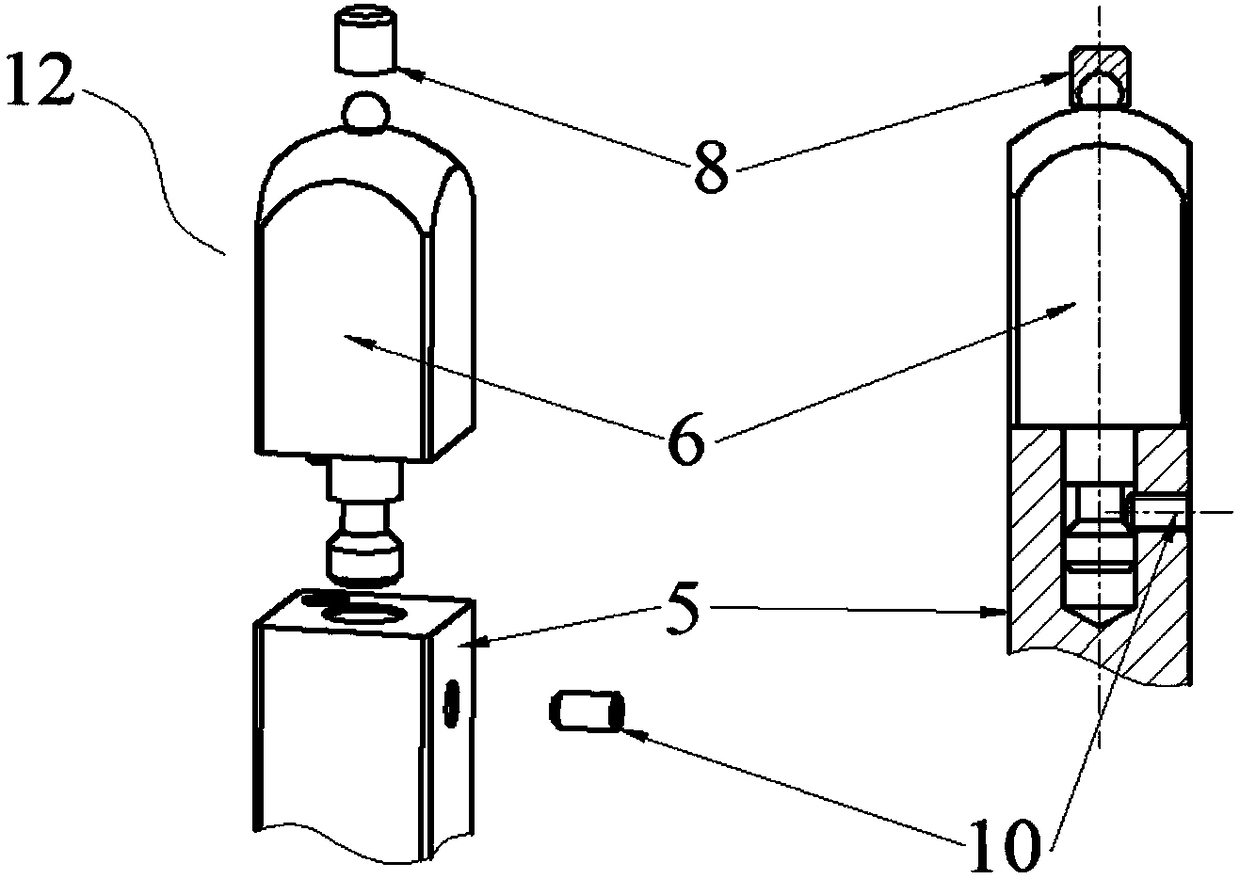

[0028] Fixed end constraint module 12: The ball head positioning pin 8 on the top of the module is connected to the fixed end base 6 through a spherical pair, and the ball head positioning pin 8 cooperates with the positioning hole on the part 1 to restrict the part 1 in two directions in the installation plane degrees of freedom of movement.

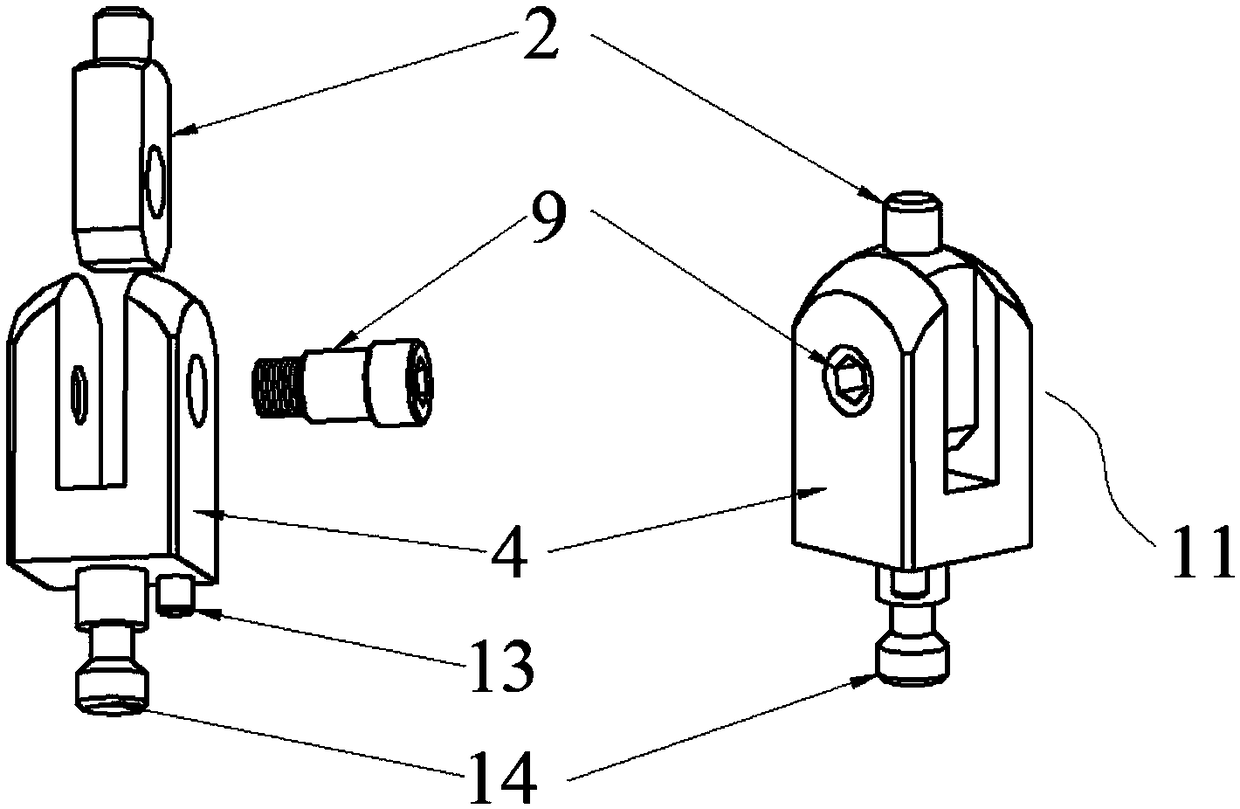

[0029] Mobile end constraint module 11: This module is composed of mobile end base body 4, screw 9, and rotating positioning pin 2. The rotating positioning pin 2 can rotate along the axis of the screw 9, and the rotating positioning pin 2 cooperates with the positioning hole on the part to restrict the part 1 rotational degrees of freedom in the mounting plane.

[0030] The bottom structure of the base body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com