Milling cutter clamping device convenient to install

A milling cutter holder and milling cutter technology, which is applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of milling cutter deflection and falling off, inconvenient replacement, and small holding force, so as to achieve simple structure and improve work efficiency. Efficiency, enhance the effect of blessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

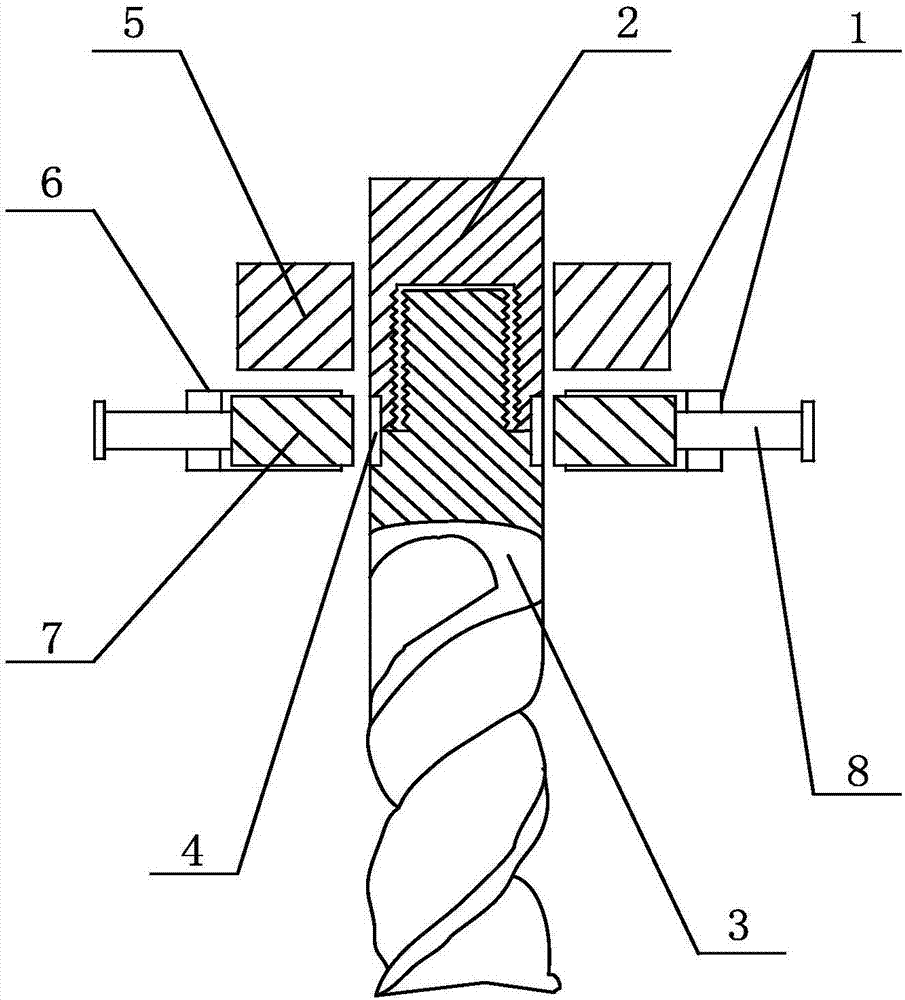

[0021] Such as figure 1 As shown, the present invention is an easy-to-install milling cutter clamping device, comprising a clamping seat 1, a milling cutter shank 2 fixed on the clamping seat, a milling cutter head 3 connected to the lower end of the milling cutter shank, and a milling cutter The knife handle and the milling cutter head are connected by threads, and the connection between the milling cutter handle and the milling cutter head is provided with a plurality of limit grooves 4; the clamping seat includes a knife handle clamping seat 5 and a limit Position clamping seat 6, the knife handle clamping seat is used for clamping the milling cutter shank, and the described limit clamping seat is positioned at the outside of the junction of the milling cutter handle and the milling cutter head, and the limit clamping seat is provided with Limit block 7, the shape of the limit block matches the shape of the limit groove, and the limit block moves back and forth along the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com