Intelligent automatic cutting device

An automatic cutting, one-pair technology, applied in metal processing and other directions, can solve problems such as low cutting efficiency, and achieve the effect of simple and reasonable settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

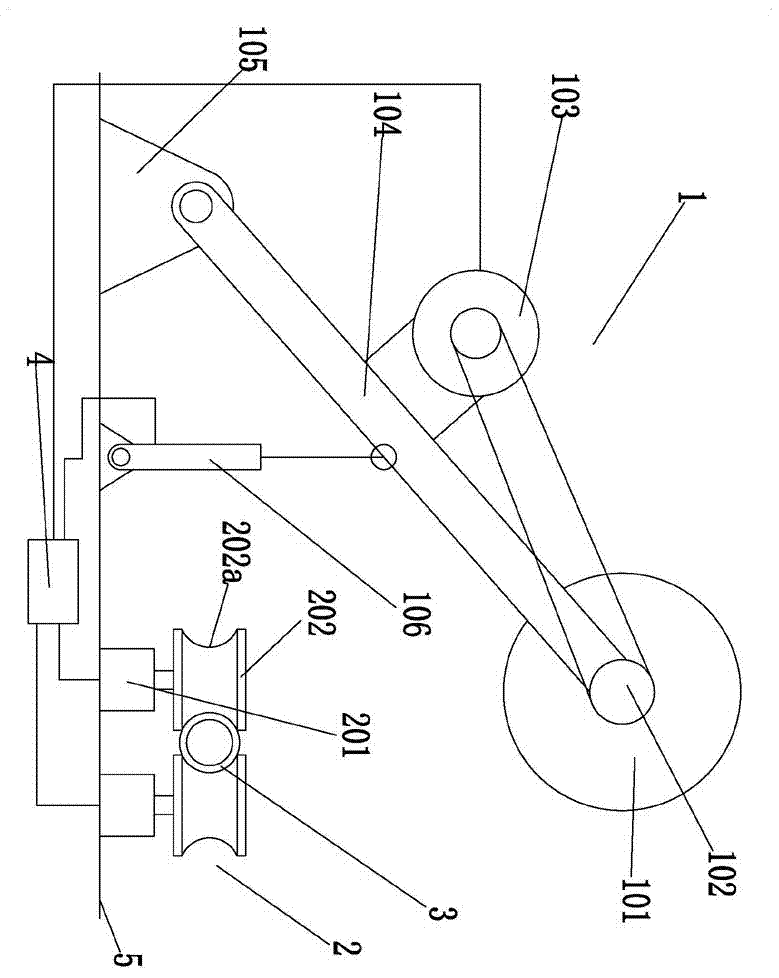

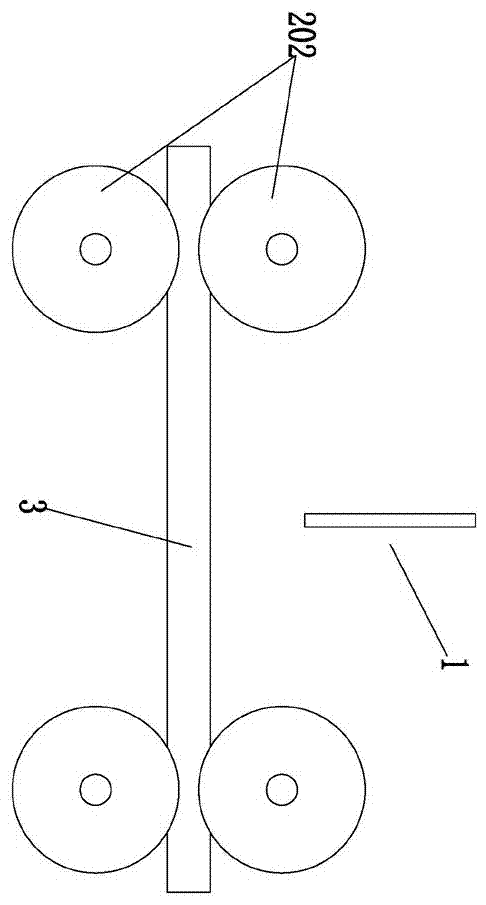

[0012] Such as Figure 1-2 As shown, an intelligent automatic cutting device includes a cutting assembly 1, a feeding assembly 2, and an electric control center 4.

[0013] The above-mentioned feeding assembly 2 is provided with two pairs, and the two pairs of feeding assemblies 2 are arranged at intervals, and each pair of feeding assemblies 2 is arranged side by side. The feeding assembly 2 includes a bottom drive motor 201 and a feed wheel 202. The bottom drive motor 201 is fixed on the ground foundation 5 The feeding wheel 202 can perform horizontal rotation under the control of the bottom drive motor 201. The feeding wheel 202 is a rotary structure and its central axis is the center of rotation. The outer periphery of the feeding wheel 202 is provided with an arc groove 202a. When feeding, each pair of feeding components The arc-shaped grooves 202a of 2 all clamp and hug the outer periphery of the pipe material 3.

[0014] The above-mentioned cutting assembly 1 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com