Electromechanical tracking power supply device

A technology of power supply device and mobile power supply, which is applied in circuit devices, electric vehicles, current collectors, etc., can solve the problems of difficulty in realizing electric machinery, shortening the surface of power supply and receiving surface, and increasing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

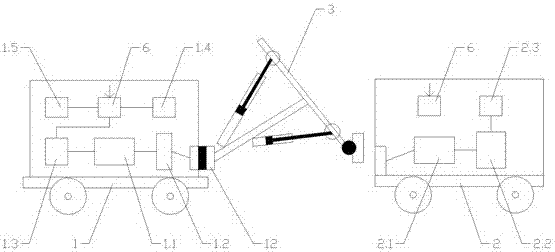

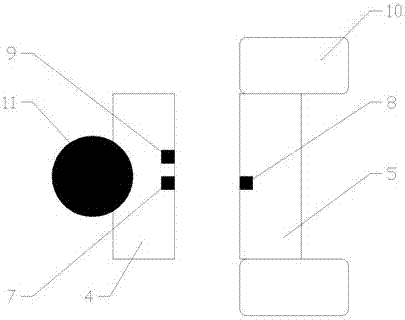

[0027] Example 1: Combining figure 2 As shown, the power supply joint is a power supply plate 4 capable of emitting electromagnetic waves, the power supply plate 4 is equipped with a force sensor 9 , the power receiving joint is a power receiving plate 5 capable of receiving electromagnetic waves, and the power receiving plate 5 is surrounded by insulating materials 10 . After the power supply plate 4 and the power receiving plate 5 are in contact, the contact state of the two is sensed by the force sensor 9. When the electric machine 2 is moving, the manipulator control device 1.4 on the movable power supply vehicle 1 controls the manipulator 3 to move accordingly and keep in contact. The force is within a certain range, so that the power supply board 4 and the power receiving board 5 are always tightly connected.

[0028] In addition, the power supply plate 4 is connected to the manipulator 3 through the ball joint 11, and the manipulator 3 is connected to the movable power...

Embodiment 2

[0029] Embodiment 2: The difference with Embodiment 1 is that the power receiving plate 5 is provided with a holding device capable of fixing the power supply plate 4, such as a magnetic device. After the manipulator 3 places the power supply plate 4 on the power receiving plate 5, the receiving plate The electric plate 5 emits an electromagnetic suction force to attract the power supply plate 4 on the electric receiving plate 5, and the manipulator control device 1.4 relaxes the driving force of each joint on the manipulator 3, and the manipulator 3 can freely stretch and contract along with the movement of the electric machine 2, so that There is no need to continuously control the manipulator 3 during the power supply process to maintain the pressure of the power supply plate 4 on the power receiving plate 5, and when the electric machine 2 suddenly accelerates or decelerates, each joint will be in a braking state, thereby slowing down the speed change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com