Platform door structure, platform guardrail manufacturing method and setting method

A manufacturing method and platform door technology, which is applied to building structures, stations, door/window accessories, etc., can solve problems such as the cost impact of platform guardrails, and achieve the effect of setting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0025] It usually takes several weeks to complete the platform railing on the platform. Thus, causing passengers to enter the train through unfinished platform guardrails. Or, cause passengers to disembark from the train through an unfinished platform barrier. In the following description, the term "platform door structure" refers to an unfinished platform guardrail (a state in which some door units have not yet been installed). In the first embodiment, an exemplary platform door structure capable of performing safety confirmation on the condition that the door space is in a closed state will be described.

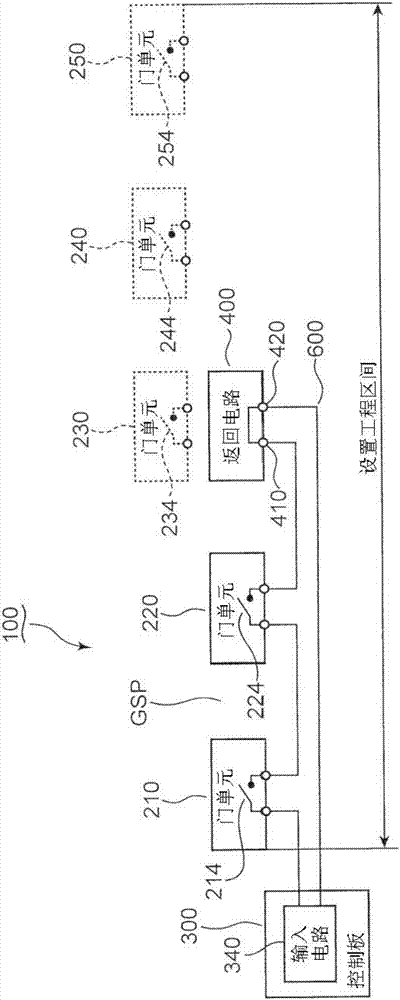

[0026] figure 1 It is a schematic diagram of the platform door structure 100 of 1st Embodiment. refer to figure 1 The platform door structure 100 will be described.

[0027] figure 1 Door units 210 , 220 , 230 , 240 , 250 are shown schematically. The platform guardrail is completed by arranging the door units 210, 220, 230, 240, 250 on the platform (not shown). fig...

no. 2 approach

[0079] With the technology described in connection with the first embodiment, the operator can arrange the return circuit near the door unit installed on the platform. However, according to the technique of the first embodiment, a worker needs to move the return circuit every time a door unit is added. In 2nd Embodiment, the technique which can add a gate unit to a closed loop circuit without an operator moving a return circuit is demonstrated.

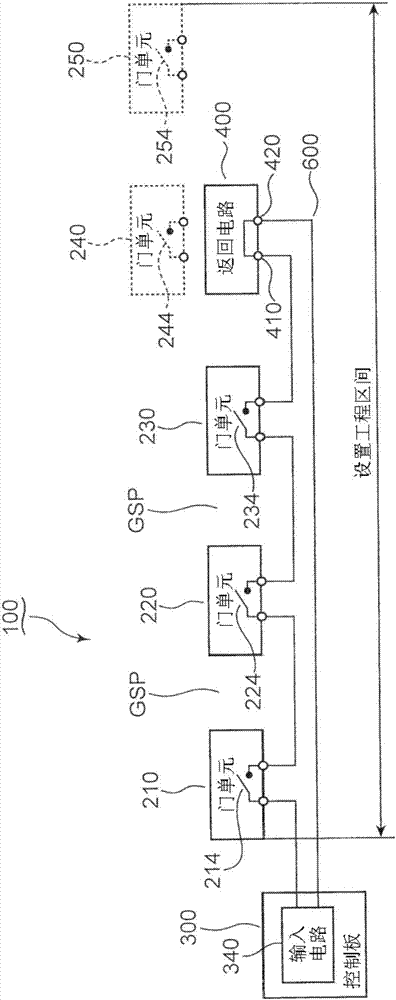

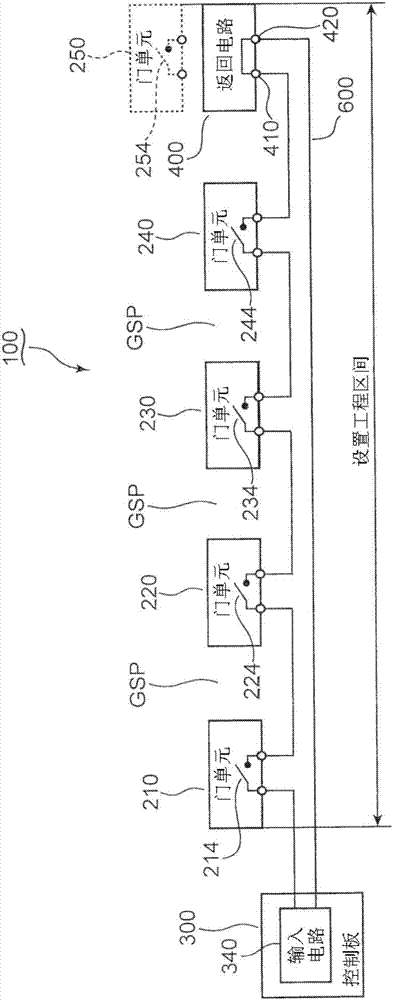

[0080] Figure 6 It is a schematic diagram of 100 A of platform door structures of 2nd Embodiment. refer to figure 2 , Figure 4 to Figure 6 The platform door structure 100A will be described. The same reference numerals are assigned to the same elements as in the first embodiment. The description of the first embodiment is referred to the components denoted by the same reference numerals.

[0081] Similar to the first embodiment, 100A of platform door structures include door units 210 and 220 and a control panel 300 . The des...

no. 3 approach

[0088] The return circuit described in connection with the first embodiment and the second embodiment may only have a function of directly outputting an input signal. Thus, the return circuit can have a very simple circuit configuration. In the third embodiment, an exemplary circuit configuration of a return circuit will be described.

[0089] Figure 9 It is a schematic plan view of the return circuit 430 of the third embodiment. refer to figure 1 , Figure 6 as well as Figure 9 The return circuit 430 will now be described.

[0090]return circuit 430 can serve as a reference figure 1 The illustrated return circuit 400 or refer to Figure 6 The illustrated return circuit 400A is used. The return circuit 430 includes a substrate 431 and a printed layer 432 . The printing layer 432 is formed on the substrate 431 .

[0091] The printing layer 432 includes a first contact portion 433 , a second contact portion 434 and a connection line portion 435 . The first contact p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com