Power cabinet for sample pneumatic conveying system

A technology of pneumatic conveying and power cabinets, applied in the field of power cabinets, can solve the problems of large energy consumption loss, complicated pipeline connection, large fan vibration, etc., and achieve the effect of ensuring physical characteristics and precision, simple pipeline connection, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

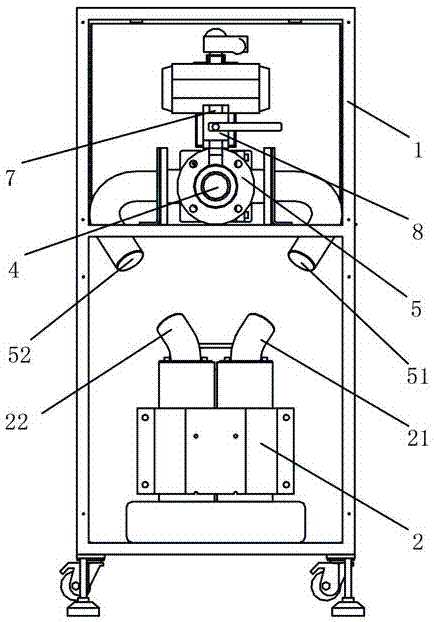

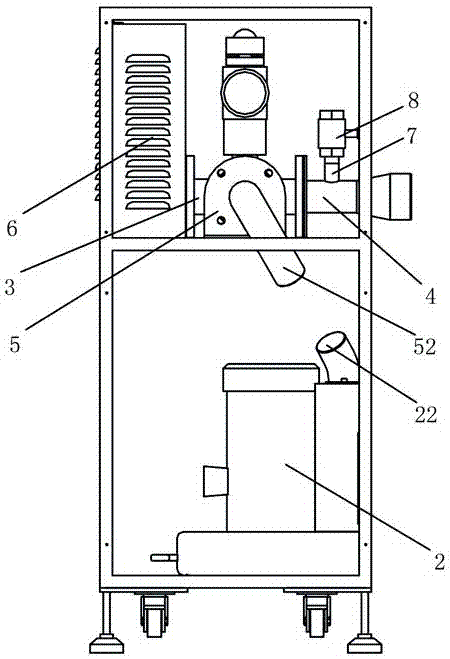

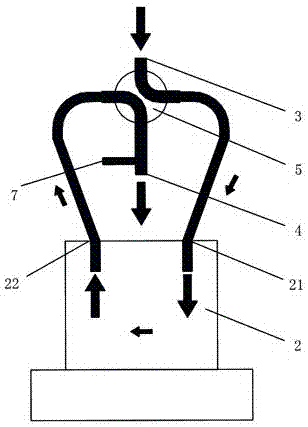

[0030] Such as Figure 1 to Figure 5 As shown, the present invention provides a power cabinet for a sample pneumatic conveying system, comprising a cabinet body 1, which is provided with a fan 2 capable of blowing and extracting air, an external ventilation pipe 3 for communicating with the outside world, and a In connection with the connecting air pipe 4 and the four-way ball valve 5 communicated with the pneumatic conveying pipeline 9, the four-way ball valve 5 is connected with the air inlet 21 and the air outlet 22 of the external air pipe 3, the connecting air pipe 4 and the blower fan 2 respectively. As shown in the figure, the four-way ball valve 5 communicates with the air inlet 21 of the fan 2 through the first ball valve interface 51 ( figure 1 The pipe used to connect the two is hidden in the middle), and the four-way ball val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com