Four-point leveling hydraulic scissor elevating railway line maintenance platform

A four-point leveling and line inspection technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of deviation and other problems, achieve the effect of small space, increase the operating space, and expand the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

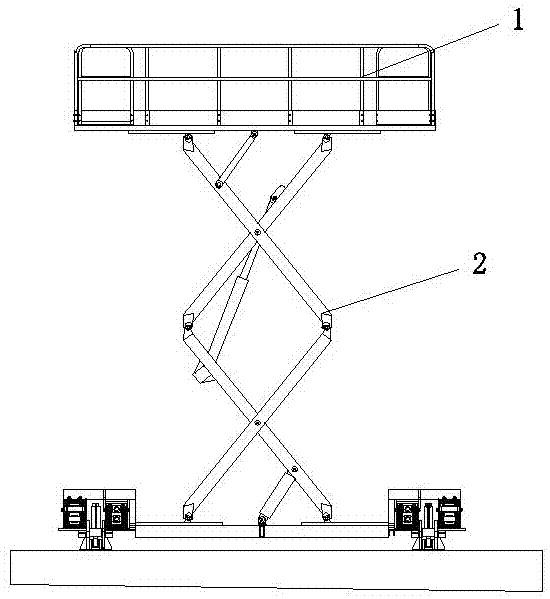

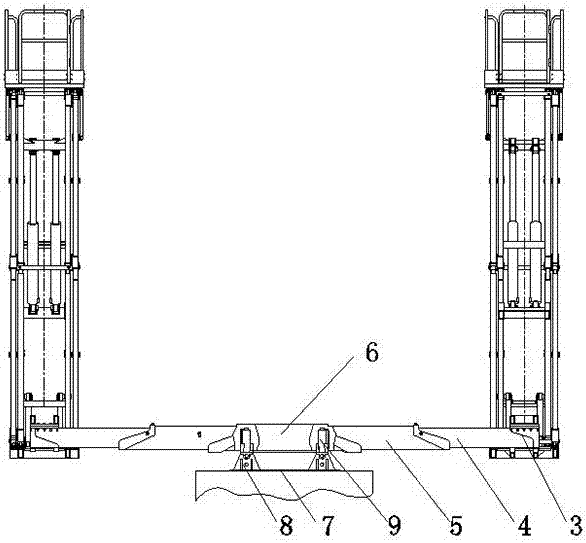

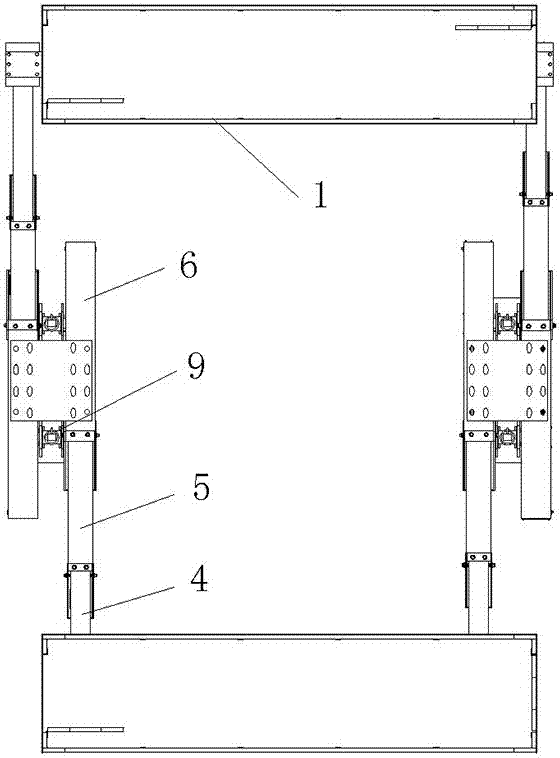

[0017] Such as Figure 1 to Figure 6 The shown four-point leveling hydraulic scissor lift railway line maintenance platform includes two leveling bases 7 arranged in parallel on the front and rear of the train chassis, and the left and right sides of the leveling base 7 are provided with a leveling cylinder 9 Oil cylinder trunnion support 8, the lower end of the leveling oil cylinder 9 is set on the oil cylinder trunnion support 8 through the oil cylinder pin 10, and the oil cylinder trunnion support 8 is provided with an oil cylinder trunnion for leveling the oil cylinder 9 12 movable opening chute 71; said leveling oil cylinder 9 is respectively connected with two symmetrically arranged telescopic outrigger groups, and said telescopic outrigger group is provided with outrigger box 6 fixed together with leveling oil cylinder 9, so The outrigger box 6 is sequentially connected with an outrigger 5 and two outriggers 4 through a telescopic oil cylinder 11, and the two sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com