Drying device for tea processing

A drying device and tea technology, which is applied in tea drying, drying gas arrangement, non-progressive dryer, etc., can solve the problems of incomplete tea drying, incomplete tea cleaning, and reduced air drying efficiency, and achieve consistent drying effect, Good cleaning quality and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

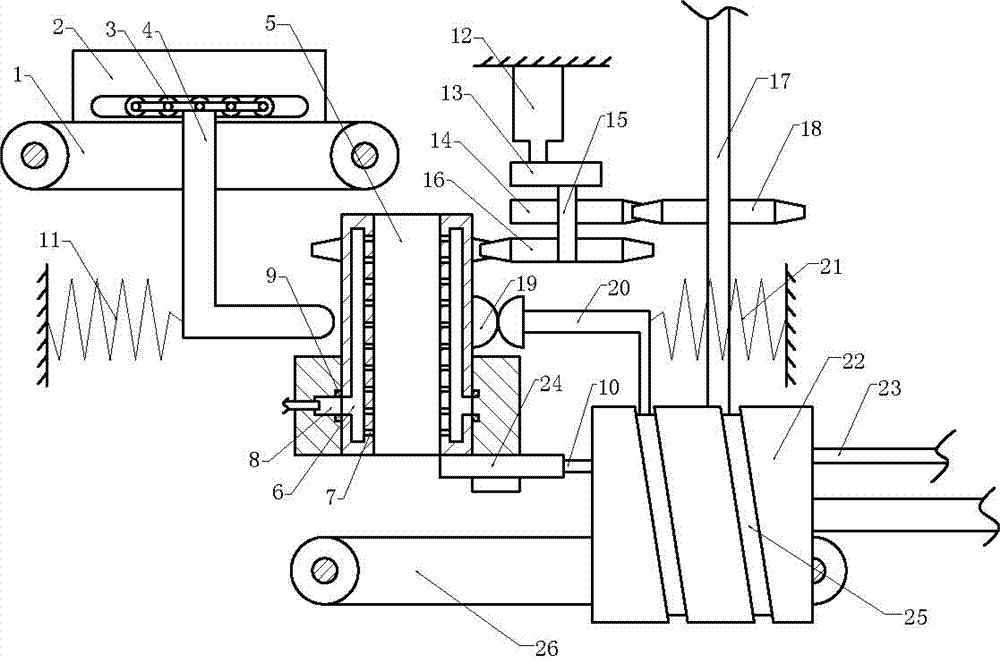

[0019] The reference signs in the drawings of the description include: the first conveyor 1, the support frame 2, the toggle shaft 3, the driving rod 4, the cleaning cylinder 5, the water inlet hole 6, the nozzle 7, the water inlet hole 8, the gasket 9, Rack 10, second spring 11, motor 12, reducer 13, sector gear 14, main shaft 15, first gear 16, rotating shaft 17, second gear 18, bump 19, push rod 20, first spring 21, Drying cylinder 22, air pipe 23, filter plate 24, spiral guide groove 25, second conveyor 26.

[0020] Example basic reference figure 1Shown: a drying device for tea processing, including a frame, a first conveyor 1, a second conveyor belt, a cleaning cylinder 5, and a drying cylinder 22. The frame is integrally formed with a support cylinder, and the bottom of the cleaning cylinder 5 is rotatably connected to the support In the cylinder, the first convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com