Assembly-type full-contact honeycomb floating disk

A full-contact and assembled technology, which is applied in chemical storage equipment, petrochemical and petroleum fields, can solve the problems of inconvenient installation of floating disc components, and achieve the effects of not easy deformation, convenient socketing and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

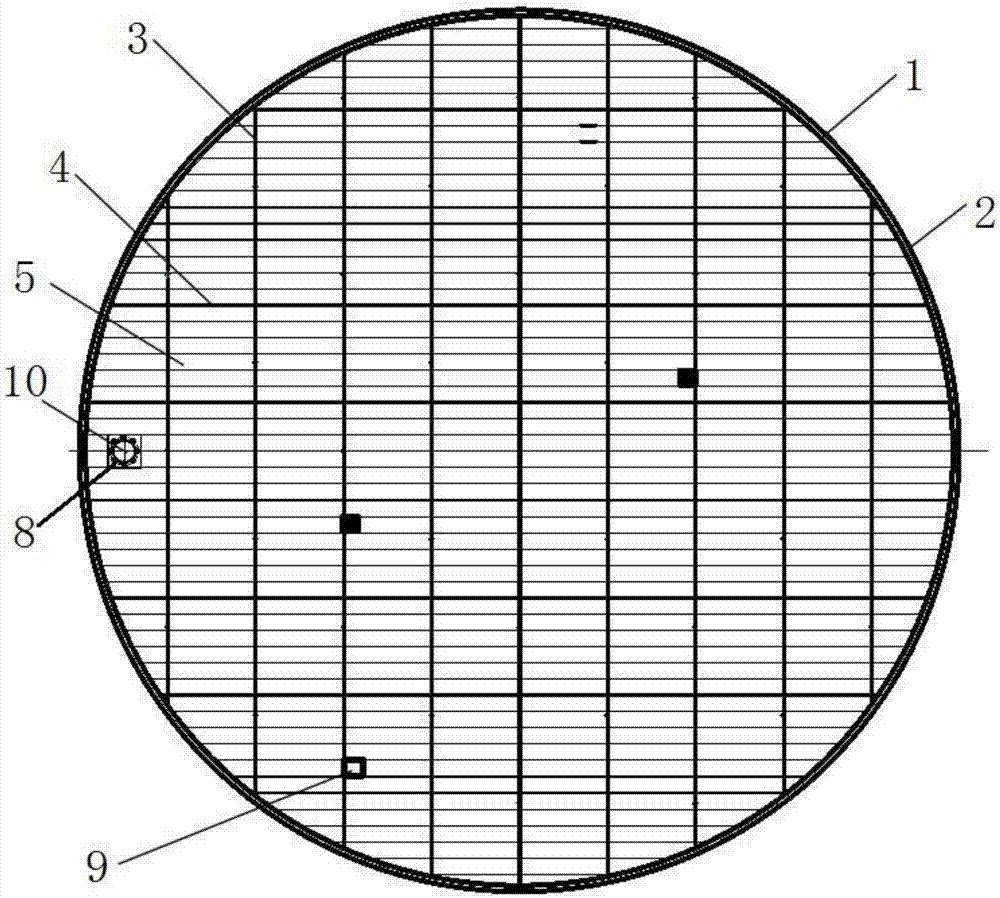

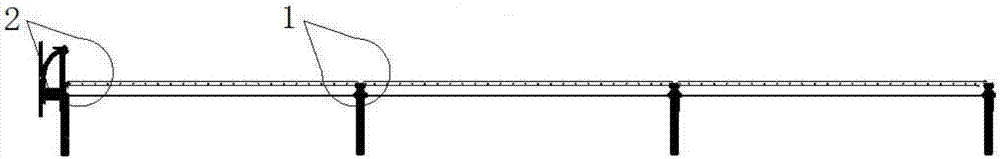

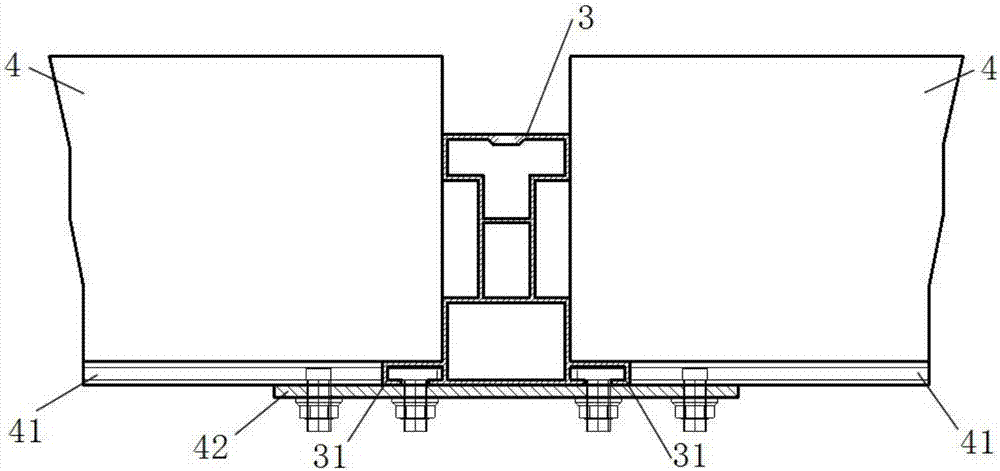

[0037] Such as figure 1 , figure 2 As shown, an assembled full-contact honeycomb floating plate includes a ring beam 1, and several elastic sealing compensation structures 2 are arranged on the outside of the ring beam 1; inside the ring beam 1, several well-shaped frames are formed by a main beam group and an auxiliary beam group , a number of honeycomb boxes 5 are arranged in the well-shaped frame; a first side wing sheath 6 is sleeved between the sub-beam group 4 and the honeycomb box 5, and a second side wing sheath is sleeved between adjacent honeycomb boxes 5 Set of 7; as image 3 As shown, two rows of first T-shaped slots 31 are arranged at the bottom of the main beam group, and the main beam group is connected with pillars through T-shaped fasteners; 4 The bottom is provided with two rows of second T-shaped slots 41, the beam conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com