A water-resistant and crack-resistant foam concrete and its preparation method

A foam concrete, foam technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

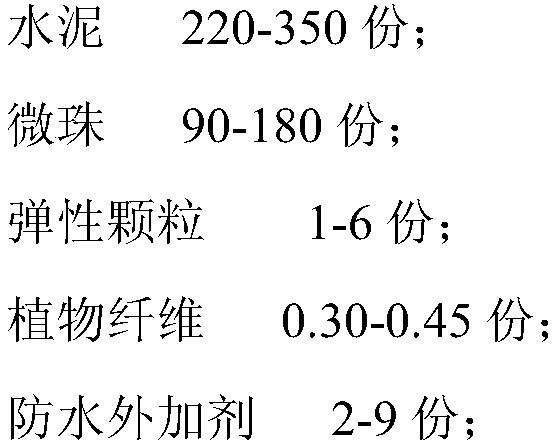

Method used

Image

Examples

Embodiment 1

[0033] Cement: 280 parts, ordinary Portland cement, P·O 42.5R grade;

[0034] Microbeads: 150 parts, metakaolin tailings powder;

[0035] Waste rubber powder: 3 parts, fineness is 120 mesh;

[0036] Palm silk: 0.35 parts, the length is 15-25mm;

[0037] Waterproof admixture: 3 parts (60-70 parts of methoxy polyethylene glycol methacrylate polycarboxylate water reducer, 1-3 parts of sodium thiocyanate, 25-30 parts of potassium methyl silicate)

[0038] Foaming agent: (9-13 parts of lauryl dimethyl betaine, 2-3 parts of collagen powder) 16 parts, 78 parts of water, (fatty acid polyethylene glycol ester, hydroxypropyl methylcellulose element) 7 parts.

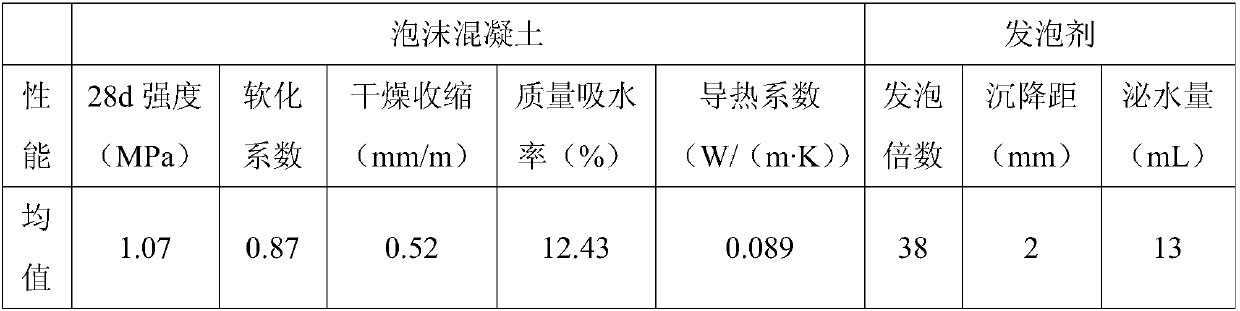

[0039] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0040]

Embodiment 2

[0042] Cement: 320 parts, ordinary Portland cement, P·O 42.5R grade;

[0043] Microbeads: 110 parts, 55 parts each of metakaolin tailings powder and waste glass powder;

[0044] Waste rubber powder: 2 parts, fineness is 120 mesh;

[0045] Palm silk: 0.30 parts, the length is 15-25mm;

[0046] Waterproof admixture: 5 parts (methoxy polyethylene glycol methacrylate polycarboxylate water reducer 60-70 parts, sodium thiocyanate 1-3 parts, potassium methyl silicate and polyacrylamide 25-30 parts )

[0047] Foaming agent: (9-13 parts of coconut oil fatty acid diethanolamide, 2-3 parts of microbial protein liquid) 15 parts, 70 parts of water, (propylene oxide-ethylene oxide polyether polyol, hydroxypropyl methyl cellulose) 7 parts.

[0048] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0049]

Embodiment 3

[0051] Cement: 285 parts, ordinary Portland cement, P·O 42.5R grade;

[0052] Micro-beads: 90 parts, steel slag fine powder;

[0053] Waste rubber powder: 5 parts, fineness is 130 mesh;

[0054] Palm silk: 0.45 parts, the length is 15-25mm;

[0055] Waterproof admixture: 4 parts (60-70 parts of methoxy polyethylene glycol methacrylate polycarboxylate superplasticizer, 1-3 parts of sodium thiocyanate, 25-30 parts of polymer emulsion)

[0056] Foaming agent: (9-13 parts of dodecyl dimethyl betaine salt and alkyl glycoside quaternary ammonium salt, 2-3 parts of tea saponin) 17 parts,

[0057] 80 parts of water, 8 parts of (silicon resin polyether emulsion, pentaerythritol fatty acid ester).

[0058] Prepare foaming agent and 400-grade foamed concrete test blocks according to the above ratio, and measure its performance as follows:

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com