Method for clothes cleaning with steam

A clothes washing and steaming technology, which is applied in the field of clothes washing, can solve the problems of long washing time, difficult absorption of steam, inability to stretch clothes and wrinkle removal, and achieve the effect of reducing heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

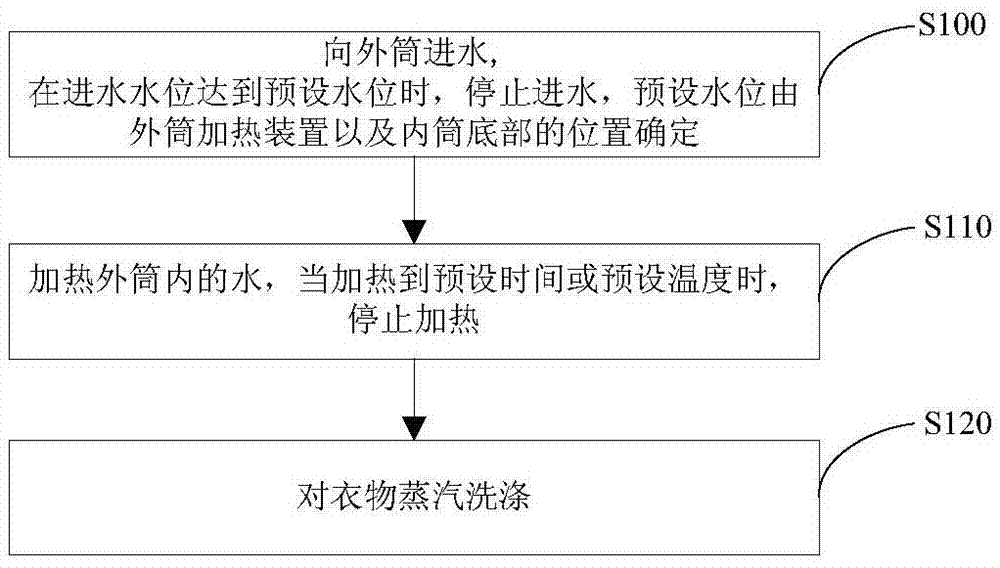

[0031] figure 1 It is a schematic flow chart of the method for using steam to wash clothes according to the present invention, referring to figure 1 Shown, the present invention provides a kind of method utilizing steam to carry out clothes washing, comprises the following steps:

[0032] S100: Enter water into the outer cylinder, and stop water intake when the water inlet level reaches a preset water level, the preset water level is determined by the heating device of the outer cylinder and the position of the bottom of the inner cylinder;

[0033] That is to open the water inlet valve of the washing machine, and enter the water in the outer cylinder of the washing machine to use as generating steam. In the present embodiment, the water inlet valve can be selected as a solenoid valve, and the controller of the washing machine is used to control the opening and closing.

[0034] Before opening the water inlet valve to enter the water, it is necessary to set a preset water lev...

Embodiment 2

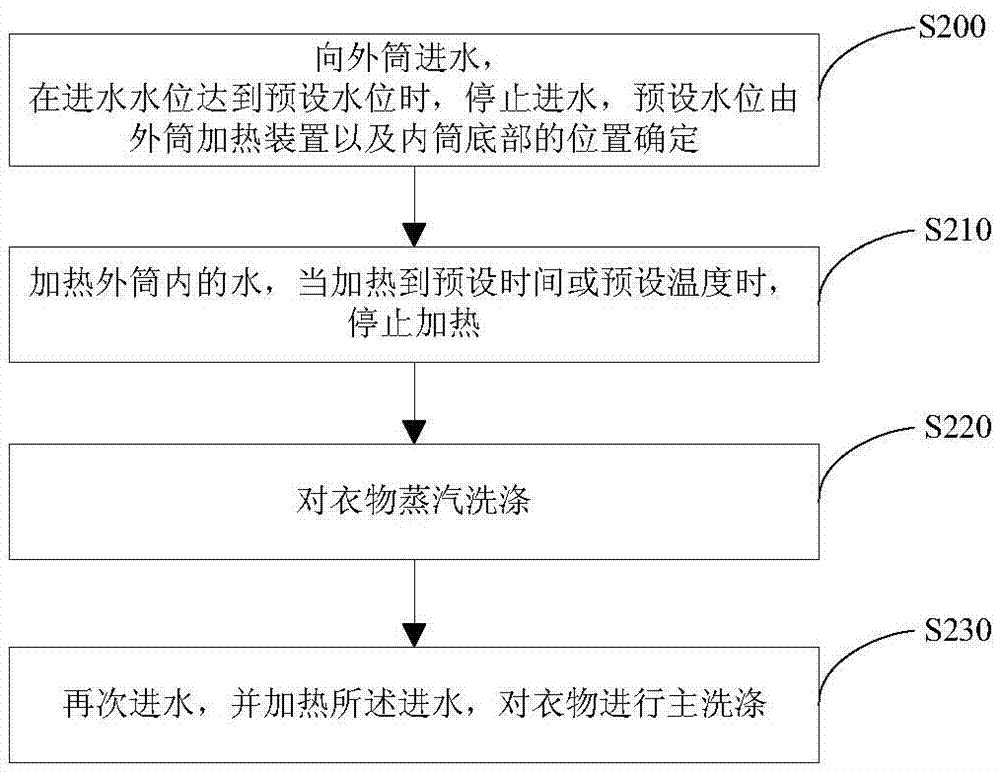

[0048] This embodiment increases the main washing process on the basis of embodiment one, specifically, refer to figure 2 , a method for washing clothes using steam in this embodiment, comprising the following steps:

[0049] S200: Feed water into the outer cylinder, and stop water inflow when the water inlet level reaches a preset water level, the preset water level is determined by the heating device of the outer cylinder and the position of the bottom of the inner cylinder;

[0050] S210: heating the water in the outer cylinder, and stop heating when the water reaches the preset time or preset temperature;

[0051] S220: steam washing the clothes.

[0052] S230: Water is fed in again, and the water is heated to perform main washing on the clothes.

[0053] That is, after the steam washing of the clothes is completed, the water inlet valve is opened to continue to feed water into the outer cylinder until the clothes are fully soaked by the water, and then the water is sto...

Embodiment 3

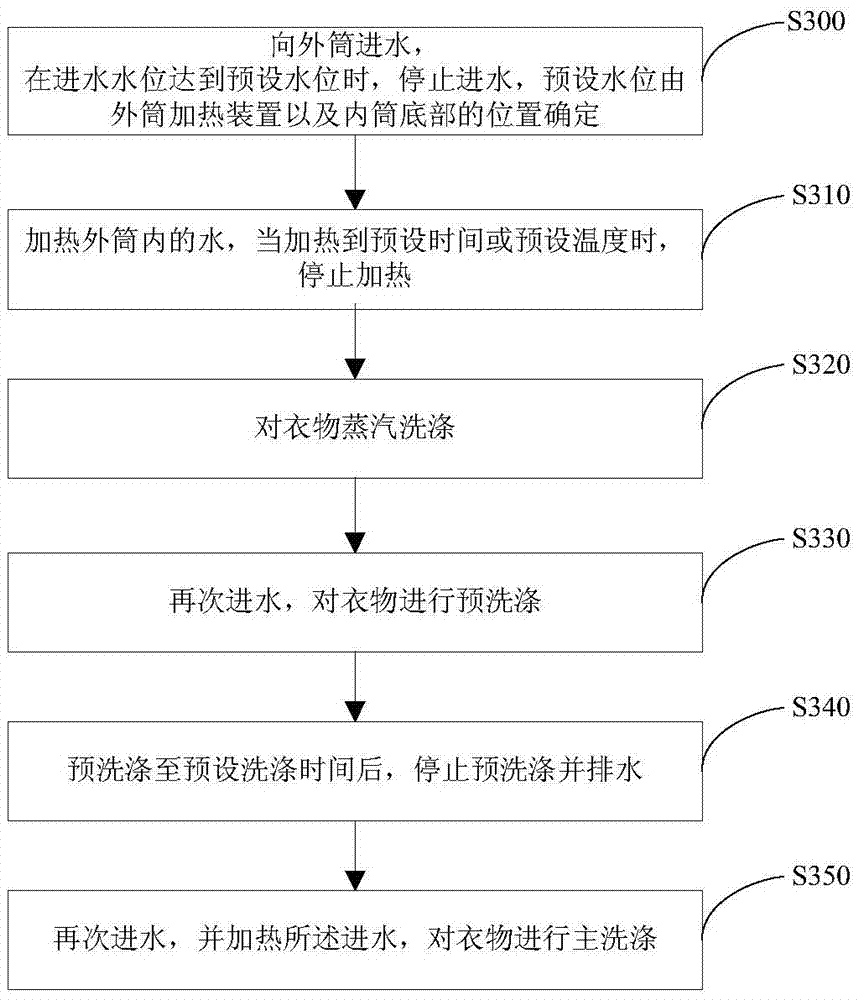

[0057] This embodiment is improved on the basis of Embodiment 2, and a new pre-washing process is added. Specifically, refer to image 3 , a method for washing clothes using steam in this embodiment, comprising the following steps:

[0058] S300: Enter water into the outer cylinder, and stop water intake when the water inlet level reaches a preset water level, the preset water level is determined by the heating device of the outer cylinder and the position of the bottom of the inner cylinder;

[0059] S310: heating the water in the outer cylinder, and stop heating when the water reaches the preset time or preset temperature;

[0060] S320: steam washing the clothes.

[0061] S330: Entering water again to pre-wash the clothes;

[0062] Pre-washing refers to the washing process of removing dirty stains or larger particles on the clothes before the main washing. After the steam washing is finished, select the pre-washing program. At this time, the water inlet valve is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com