Double-control thermostatic valve element

A thermostatic spool and spool technology, applied in the field of thermostatic valves, can solve problems such as complex waterway structure, affecting the overall appearance of the thermostatic faucet, and the overall structure of the thermostatic faucet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

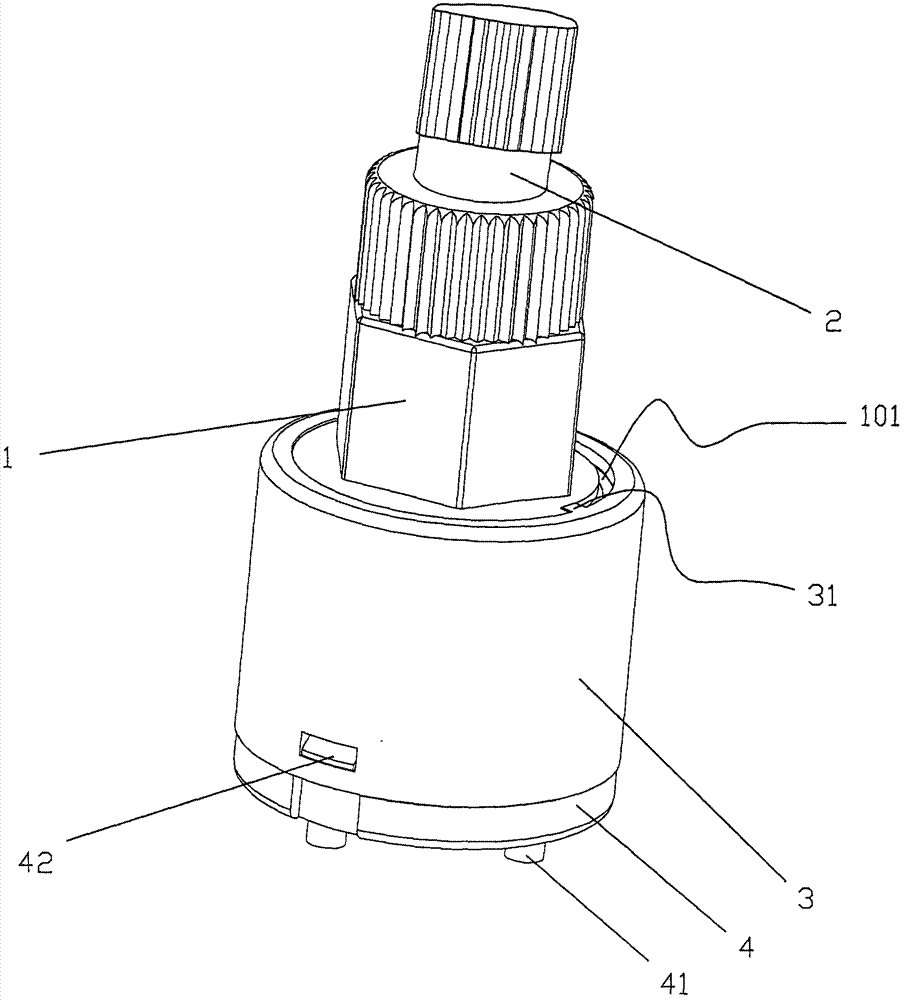

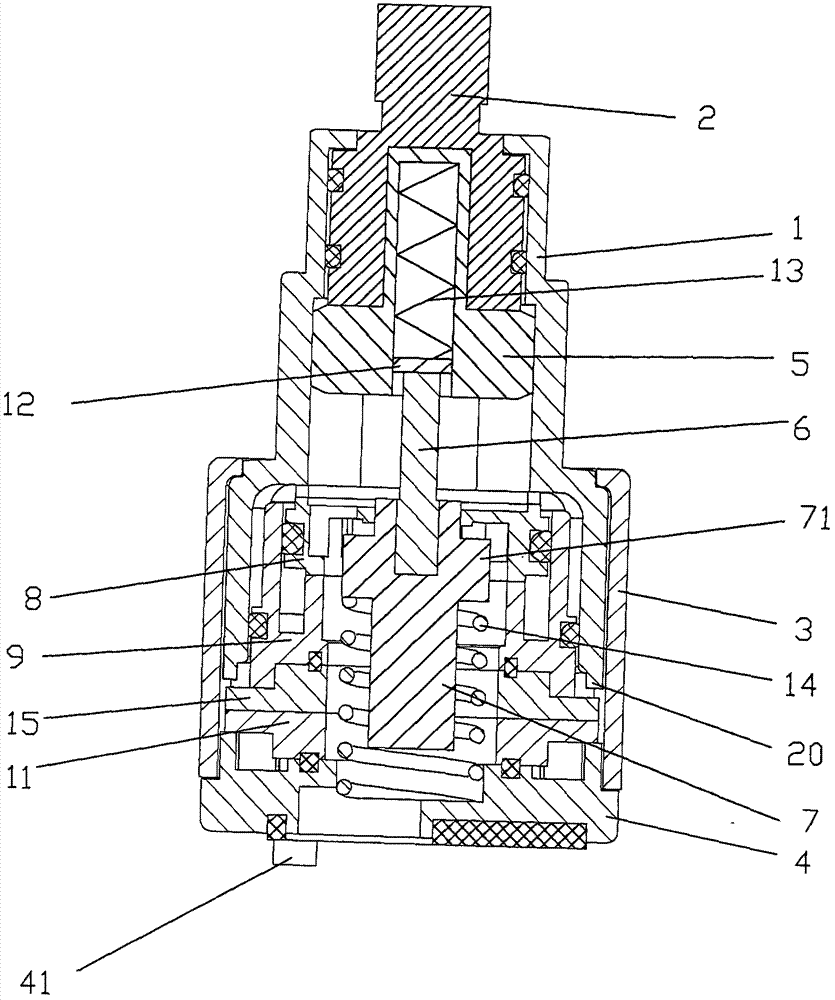

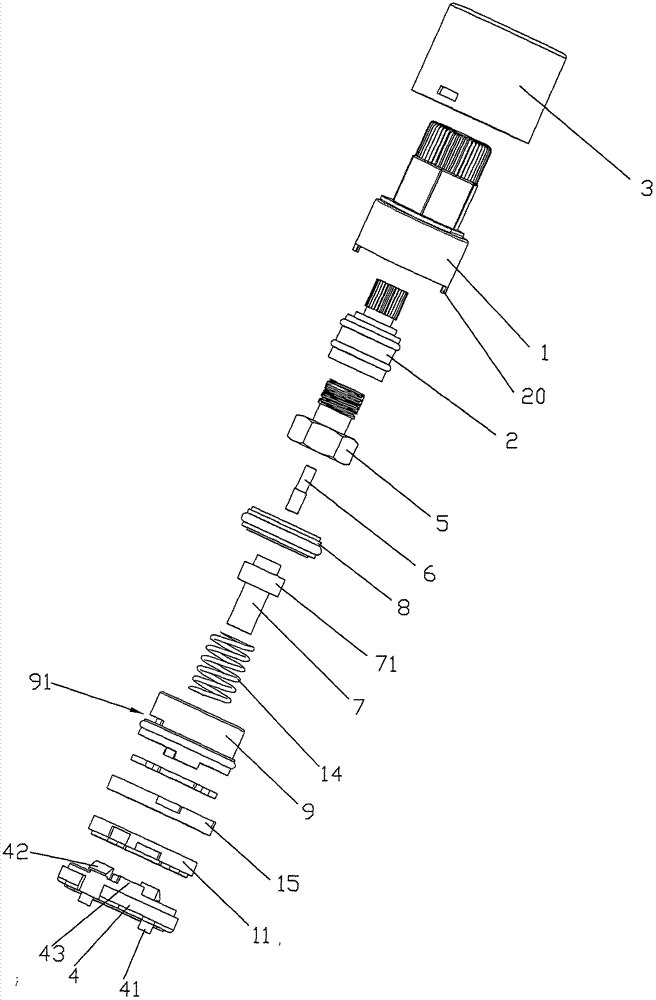

[0039] Embodiment 1, a dual-control thermostatic valve core

[0040] Such as Figure 1 to Figure 3 As shown, a dual-control thermostatic valve core includes an outer valve body 1, which is integrally injection-molded and has a stepped shape. The steps are divided into three stages, each step is circular, and the outer valve body 1 has a diameter of gradually increase from top to bottom. The outer valve body 1 is hollow inside and is used for installing a water temperature regulating mechanism. The water temperature adjustment mechanism includes an adjustment knob 2, a sliding block 5, a push rod 6, a water temperature adjustment valve core 8, a temperature sensing component and an inner valve body 9 installed in the outer valve body 1 sequentially from top to bottom. The upper end of the adjustment knob 2 protrudes from the outer valve body 1 , and the lower end is inside the upper end of the outer valve body 1 . A threaded hole is arranged at the center of the lower end of...

Embodiment 2

[0047] Embodiment 2, a dual-control thermostatic valve core

[0048] Such as Figure 13 As shown, the difference between Embodiment 2 and Embodiment 1 is that the temperature-sensing component of Embodiment 2 is a temperature-sensing spring 19 made of memory alloy, and the upper end of the temperature-sensing spring 19 is in conflict with the lower end surface of the water temperature regulating valve core 8, and the temperature-sensing spring 19 lower ends are in conflict with the base 4 upper surface. The elastic coefficient of the temperature sensing spring 19 is greater than that of the spring 13 . During use, cold water is passed into the water supply port 46, and hot water is passed into the water supply port 44, so that cold water flows out from the hot water flow channel outlet 97, and hot water flows out from the cold water flow channel outlet 91. When the hot water is cut off, the lower surface of the water temperature regulating valve core 8 is in conflict with th...

Embodiment 3

[0049] Embodiment 3, a dual-control thermostatic valve core

[0050] Such as Figure 13 As shown in Figure 14, the difference between the third embodiment and the first embodiment lies in the inner valve body 9 and the base 4. The lower end surface of the inner valve body 9 in the third embodiment is also provided with an annular extension section 910 , and the lower end of the extension section 910 is provided with a flange 911 opening toward the center of the extension section 910 . During installation, the lower end of the return spring 14 is in contact with the flange 911 at the lower end of the extension section 910 . Simultaneously, the upper surface of the base 4 is not provided with the mounting position of the back-moving spring 14, which can increase the co-flow area when the water is discharged and reduce the pressure loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com