Thread offset measuring device

A measuring instrument and thread technology, applied in the field of thread offset measuring instrument, can solve problems such as difficult to control product quality, lack of reverser nut channel, etc., and achieve the effect of accurately measuring the degree of axial deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

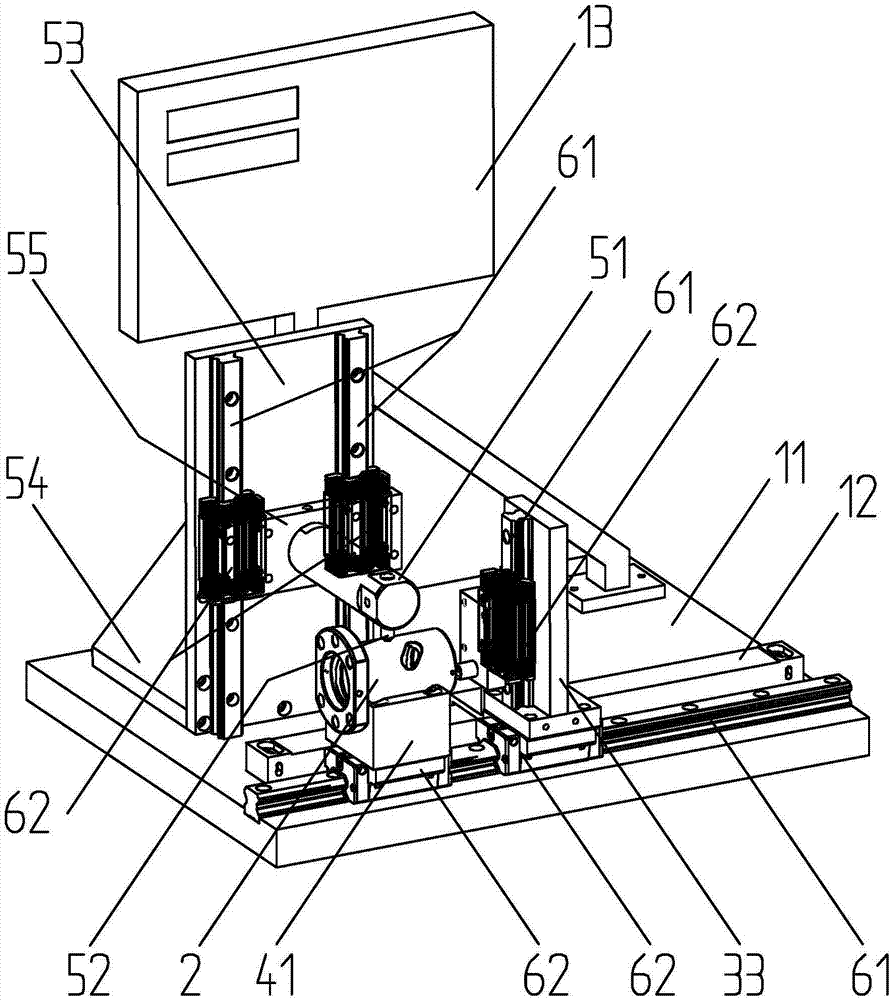

[0023] Such as figure 1 As shown, it is a thread deviation measuring instrument, which is specially used to measure the deviation of the internal thread channel of the high-precision reverser nut in the nut axial direction. The thread deviation measuring instrument includes a chassis 11, a bearing mechanism, a measuring mechanism and a positioning mechanism. The chassis is horizontally provided with a left-right linear bearing guide rail 61, and two linear bearings 62 are arranged on the linear bearing guide rail. The mechanism and the measuring mechanism can move relative to each other.

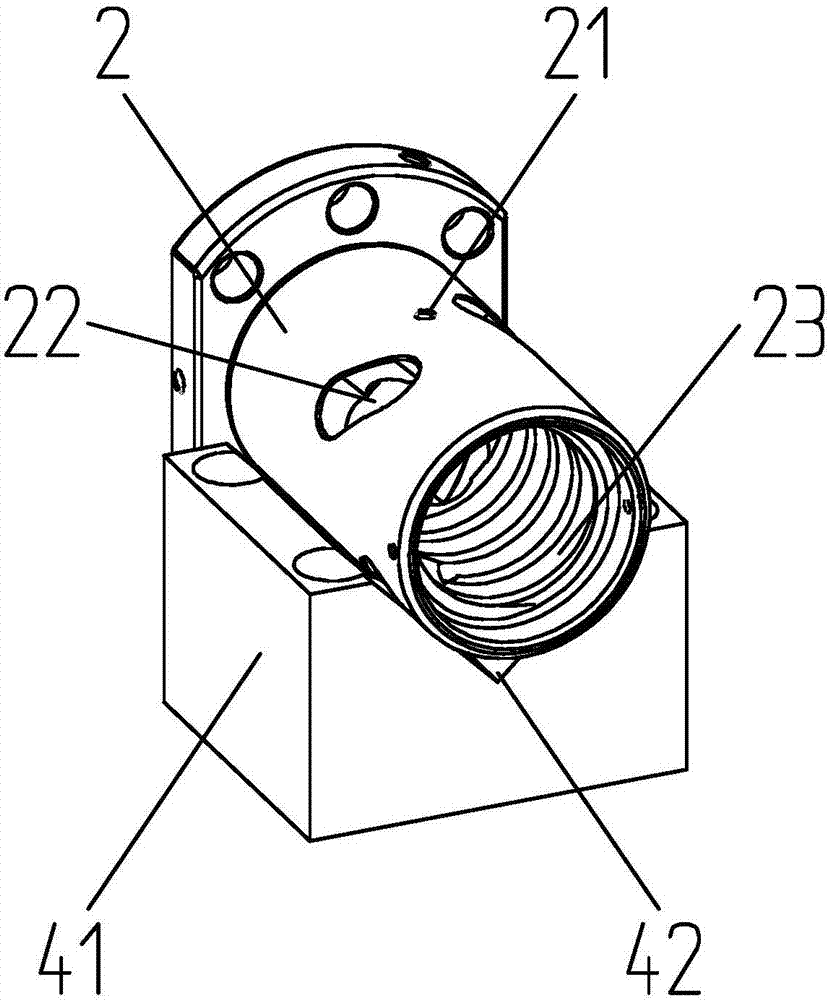

[0024] Such as figure 2 As shown, the bearing mechanism is a bearing block 41, and the bearing block is provided with a V-shaped groove 42 with an upward opening along its own slidable direction, which can be adapted to be placed on the through groove for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com