A method for detecting the stability of lsm low temperature modified asphalt mixture

A technology for modifying asphalt and mixtures, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and using repetitive force/pulse force to test the strength of materials, etc., which can solve the problem of reduced strength and stability, and soft Marshall test pieces. , the problem of high softening degree of asphalt, to achieve the effect of small internal friction angle, increased compaction degree and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. This method is applicable to the Marshall stability test and immersion Marshall stability test of LSM low-temperature modified asphalt mixture, so as to carry out the mix ratio design of asphalt mixture or the quality inspection of asphalt pavement construction. Water immersion Marshall stability test (vacuum saturated Marshall test can also be carried out) is used to test the ability of the asphalt mixture to resist spalling when it is damaged by water, and to test the feasibility of the mix ratio design by measuring its water stability.

[0036] 2. This method is suitable for forming standard Marshall cylinders and large Marshall specimens according to the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011).

[0037] 3. Stirring temperature of Marshall specimen

[0038] The LSM low-temperature modified asphalt mixture was mixed, and the mixing parameters were shown in Table 1, and a sufficient number of Marshall specime...

Embodiment 2

[0059] 1. This method is applicable to the Marshall stability test and immersion Marshall stability test of LSM low-temperature modified asphalt mixture, so as to carry out the mix ratio design of asphalt mixture or the quality inspection of asphalt pavement construction. Water immersion Marshall stability test (vacuum saturated Marshall test can also be carried out) is used to test the ability of the asphalt mixture to resist spalling when it is damaged by water, and to test the feasibility of the mix ratio design by measuring its water stability.

[0060] 2. This method is suitable for forming standard Marshall cylinders and large Marshall specimens according to the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011).

[0061] 3. The requirements for instruments and equipment meet the same requirements as in the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011) (T0709-2011).

[0062...

Embodiment 3

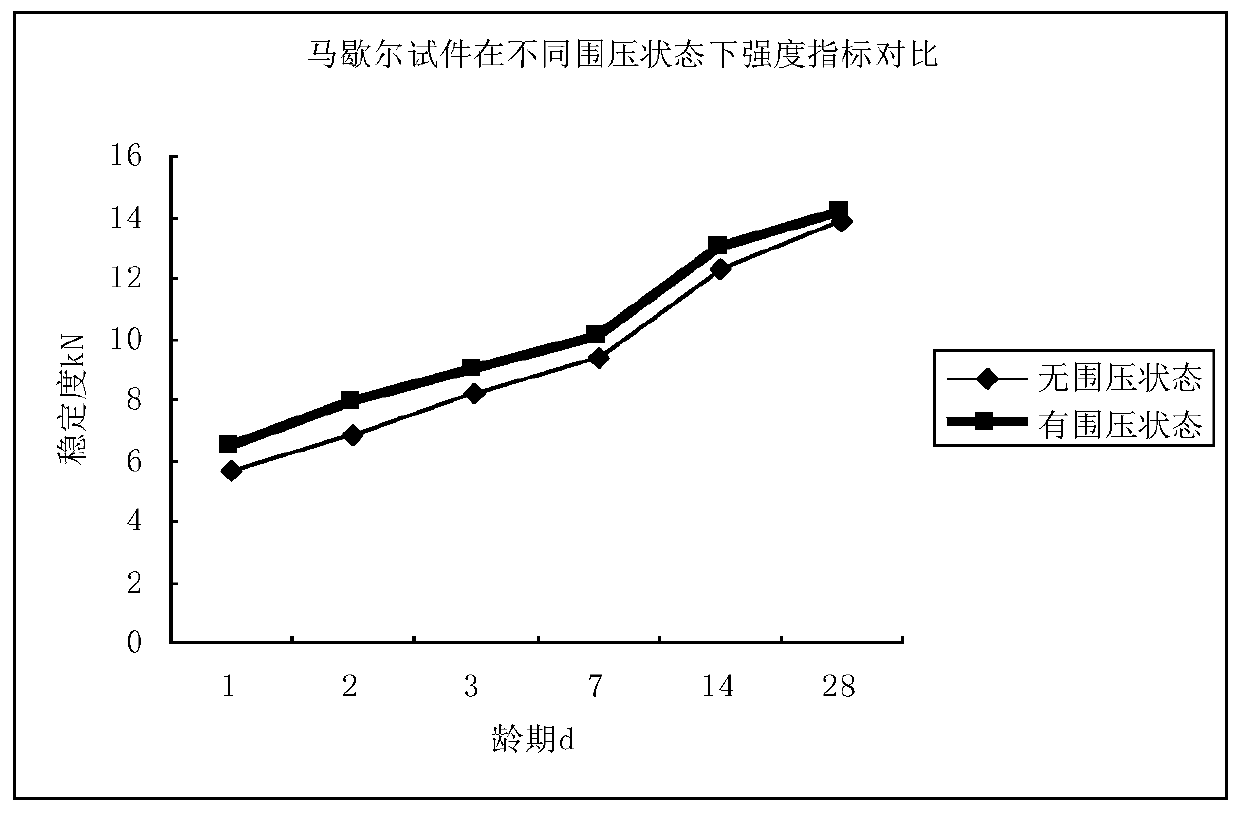

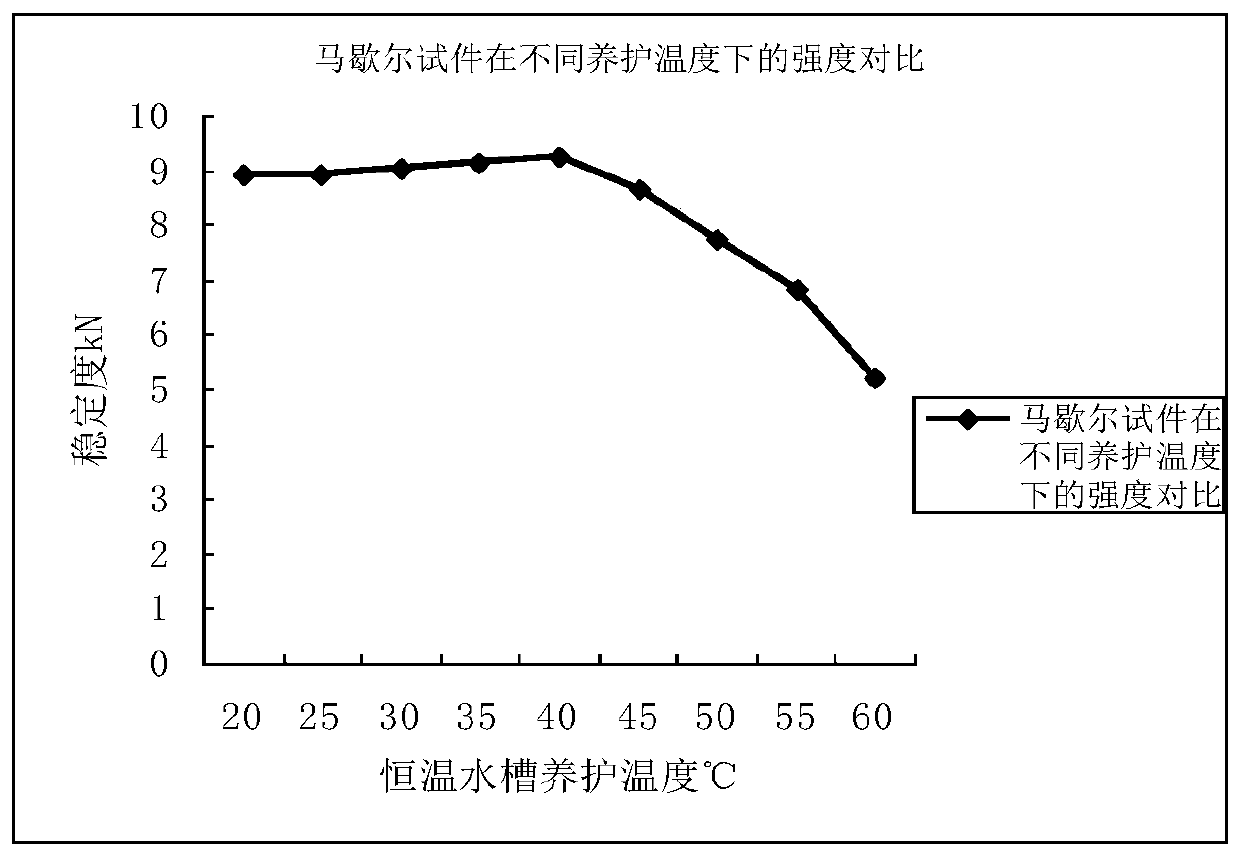

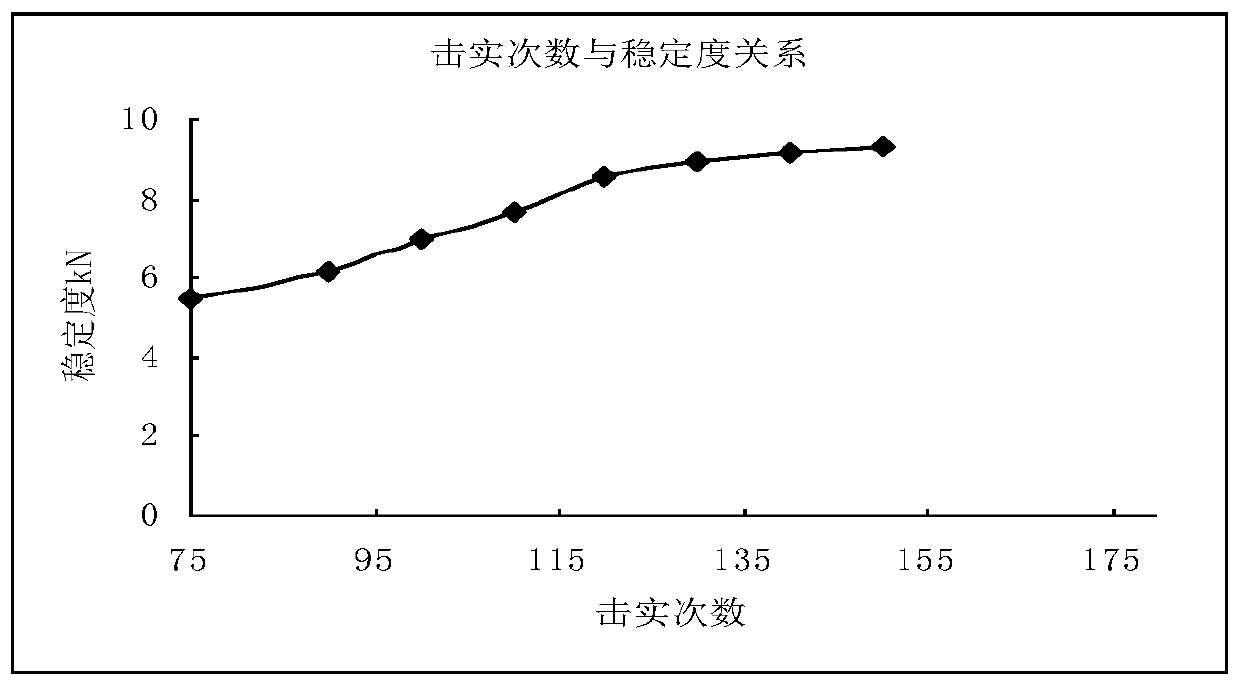

[0098] The stability of LSM low temperature modified mixture was measured according to the method of the present invention and the method stipulated in the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTGE20-2011), and the results are shown in Table 5. The inventive method: according to the optimal method that embodiment 1 and 2 draws, specifically as follows:

[0099] Step 1: mixing LSM low-temperature modified asphalt mixture, forming Marshall test pieces;

[0100] Step 2: After the Marshall test piece is formed, it is placed in the mold for 3 days, and it is demoulded after reaching the age;

[0101] Step 3: Keep the demoulded Marshall specimen in a constant temperature water tank at room temperature (15°C-25°C);

[0102] Step 4: According to the method stipulated in the current "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011), the physical indicators, stability and flow value mechanical perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com