Heat and noise reducing and speed increasing system of electronically controlled electric vehicle door

A technology of electronically controlled electric vehicles and electric vehicles, which is applied to door/window accessories, power control mechanisms, locks controlled by non-mechanical transmission, etc., which can solve the problems of complex locking action and slow closing speed, etc., and achieve small friction angle , small frictional resistance and large lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

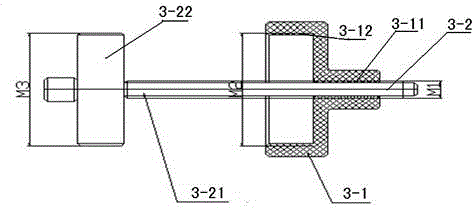

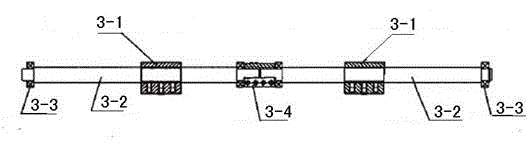

[0024] Figure 5 It is a block diagram of the locking device of the first embodiment. A form of two-in-one locking and transmission, the reduced-diameter combined nut 3-1 is composed of a small-diameter nut 3-11 and a large-diameter nut 3-12. The small-diameter nut 3-11 is screwed with the small-diameter part 3-21 of the variable-diameter combination screw to realize the rapid opening and closing of the car door, and is made of new engineering plastics with less friction coefficient (f=0.11). The large-diameter nut 3-12 is screwed together with the large-diameter part 3-22 of the variable-diameter combined screw rod to meet the mechanical self-locking condition. The large-diameter nut 3-12 is made of new engineering plastics with a relatively large friction coefficient (f=0.45). During normal operation, the small-diameter part of the variable-diameter combination screw nut moves relatively, driving the door leaf 1-1 to switch. This section has a small friction coefficient, ...

Embodiment 2

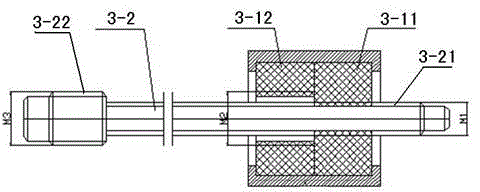

[0031] Image 6It is another form of two-in-one locking and transmission, and the reduced-diameter combined nut 3-1 is composed of a small diameter and a large diameter. The small-diameter nut 3-11 is partially screwed with the small-diameter part 3-21 [Tr16*32 (p8)] of the variable-diameter combination screw to realize the rapid opening and closing of the car door. This part has a small friction angle and a large lead. The large-diameter nut 3-12 is screwed together with the large-diameter part 3-22 [Tr104*32(p8)] of the variable-diameter combination screw rod, and the length is only 32mm to realize the locking function of the car door.

[0032] Helix angle λ λ=arc tan(s / πd)

[0033] Equivalent friction angle arc tan fv

[0034] Equivalent coefficient of friction fv fv=f / cosβ

[0035] S---screw lead s=32

[0036] d---screw middle diameter d=100

[0037] f---Friction coefficient Steel---New engineering plastic screw pair f≈0.1

[0038] π---Circle ratio π=3.1415926….

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com