A Determination Method of Optimum Cohesion Freeze Moisture Content of Cohesionless Soil

A non-cohesive soil and measurement method technology, which is applied in the field of soil mechanical performance testing of geotechnical engineering, can solve the problems of easy tilting, inability to make and form, and triaxial samples are easy to scatter, so as to achieve the reduction of cohesion, Solve the effect of easy scattering and tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

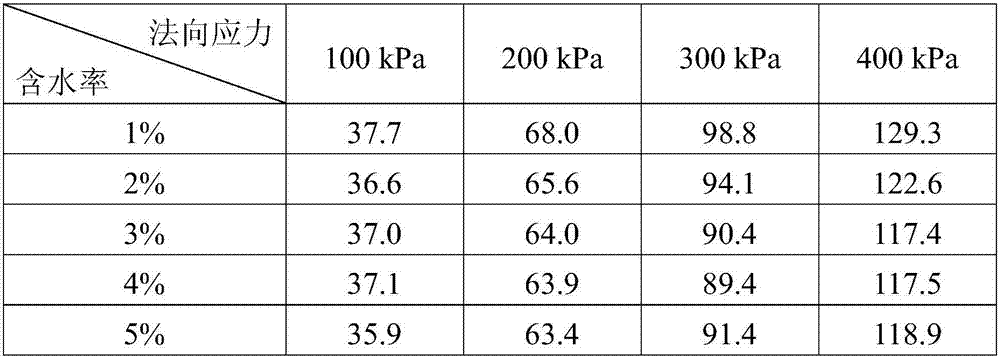

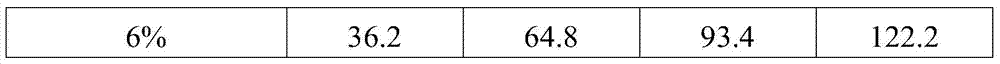

[0047] In the k5+150~k6+200 section of a high-speed railway, the roadbed has local sandy soil, which is a typical cohesive soil. Since the subgrade will be subjected to cyclic dynamic loads from trains, it is necessary to carry out triaxial mechanical properties testing of the reshaped sand. In order to prepare high-quality triaxial samples, the optimum cohesive freezing moisture content of the cohesive soil should be determined by direct shear test first.

[0048] For above-mentioned example, adopt the assay method of a kind of cohesive-free soil optimum cohesive freezing moisture content of the present invention, measure, comprise the steps:

[0049] (1), dry soil preparation:

[0050] According to the number N and dry density R of the designed direct shear samples, calculate the mass M of the dry state of the cohesive soil required for the direct shear test 2 .

[0051] N 2 =2*n 1 *n 2

[0052] m 2 =N 2 *3.14*(D / 2) 2 *h*R

[0053] Among them, n 1 is the number o...

Embodiment 2

[0084] Embodiment 2: application embodiment.

[0085] The optimal cohesion freezing water content that embodiment 1 measures is used for the sample preparation of cohesionless soil triaxial sample, specifically as follows:

[0086] 1. Preparation of mixed soil materials:

[0087] According to the design sample dry density R, the number of triaxial samples N 1 and the number of auxiliary direct shear samples N 2 , to calculate the mass M of the cohesionless soil in the dry state required for the triaxial specimen and the auxiliary direct shear test 1 and M 2 .

[0088] According to the optimum coagulation freezing water content W measured in Example 1, calculate the mixing water quality M added 3 = M 1 *W, for mixing to prepare cohesion-free soil mixture.

[0089] 2. Freezing of mixed soil materials:

[0090] Freezing the mixed non-cohesive soil material after mixing, preferably, the freezing temperature is -10°C, and the freezing time is 24 hours.

[0091] 3. Single s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com