Automobile air-conditioner compressor controller calibration system and method

A technology for automotive air-conditioning and calibration methods, which is applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve the problems of lack of calibration methods and systems for automotive air-conditioning systems, and improve control effects and adaptability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

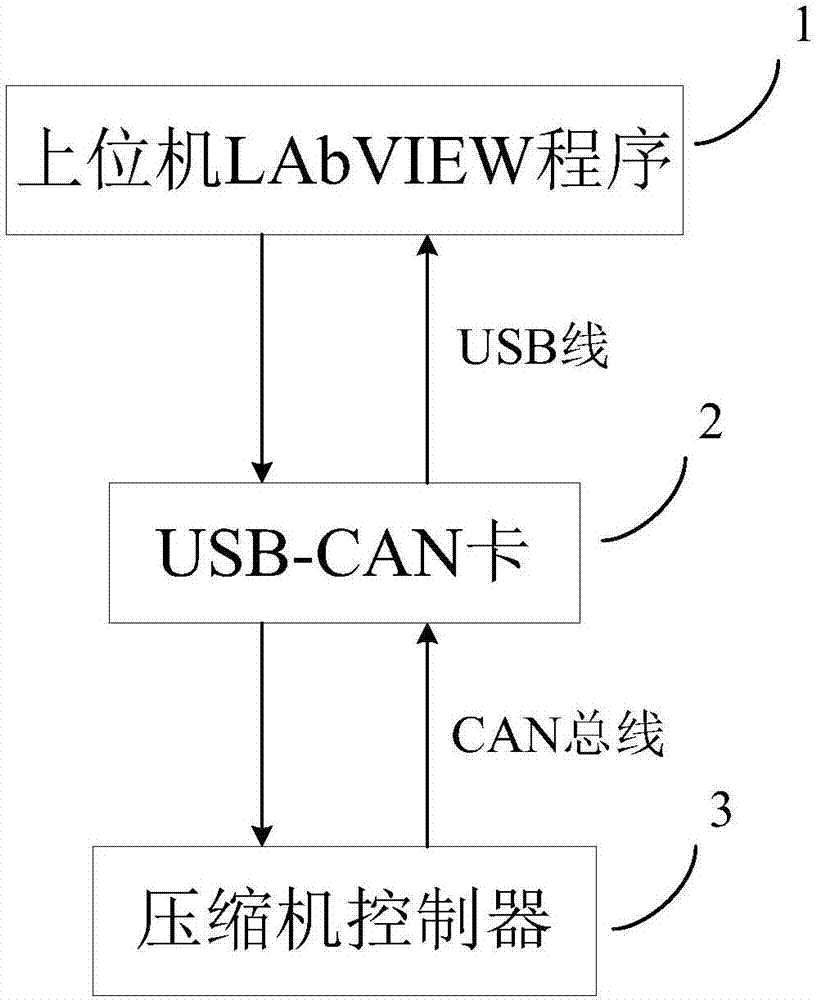

[0027] Attached below Figure 1-3 The present invention will be described in further detail.

[0028] As shown in Figure 1, the USB-CAN card 2 communicates with the compressor controller 3 through the CAN bus and communicates with the LabVIEW program 1 of the host computer through the USB cable.

[0029] After the compressor controller 3 is powered on and initialized, parameter calibration can be performed.

[0030] The LabVIEW program 1 sends a connection instruction to the compressor controller 3 according to the CCP (CAN Calibration Protocol) protocol, and waits for the compressor controller 3 to return an instruction of successful connection, thereby establishing communication.

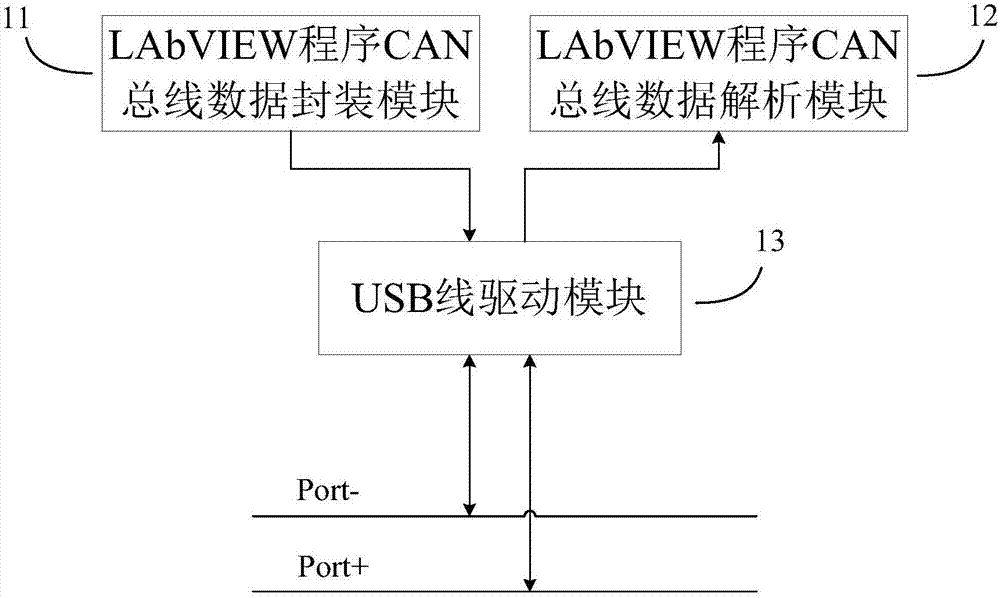

[0031] The connection instruction needs to be packaged by the CAN bus data package module 11 of the LabVIEW program, and then sent to the USB-CAN card 2 by the USB line driver module 13.

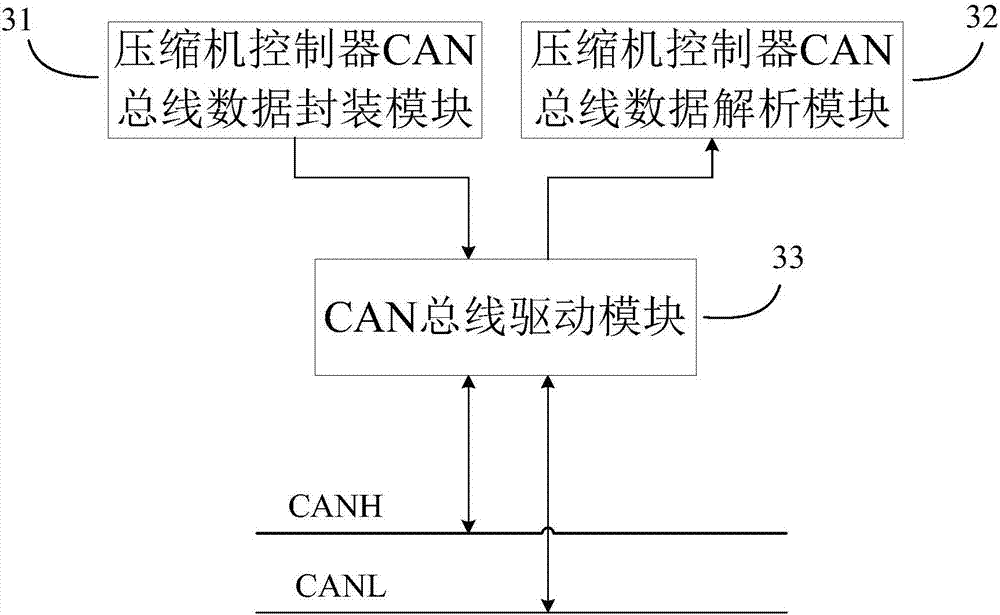

[0032] The CAN bus driving module 33 receives instructions from the USB-CAN card 2, and the compressor controller CAN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com