Lithium battery module connection structure having self-protection function and connection method of lithium battery module connection structure

A connection structure and battery module technology, applied in battery pack parts, structural parts, secondary batteries, etc., can solve the problems of runaway expansion, difficult to guarantee the safety performance of battery modules, and no self-protection module function, and achieve electrical conductivity. Good performance, low melting point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

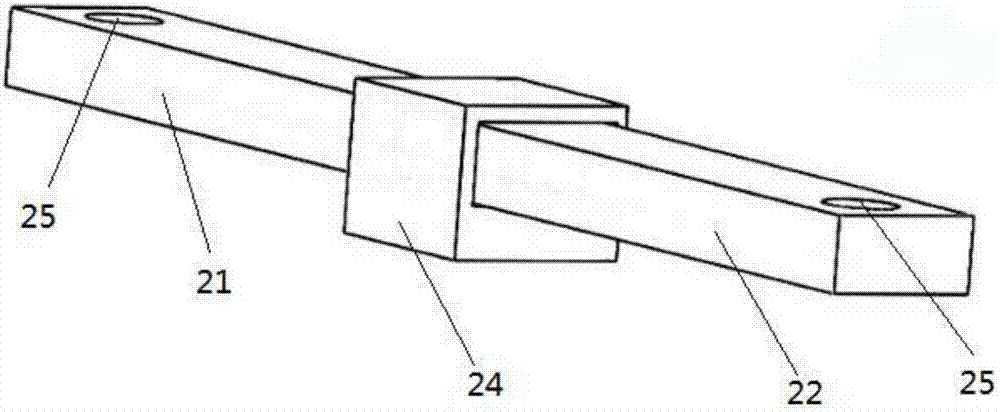

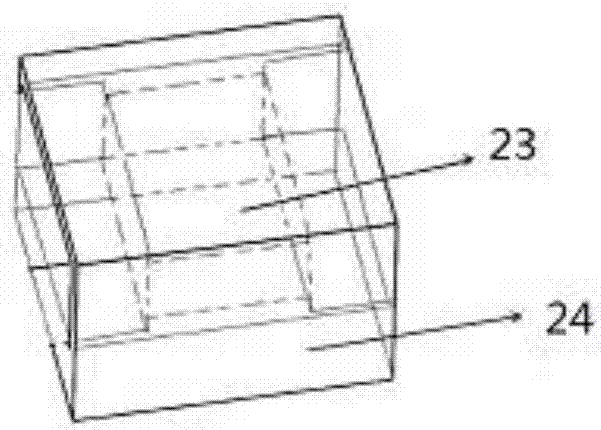

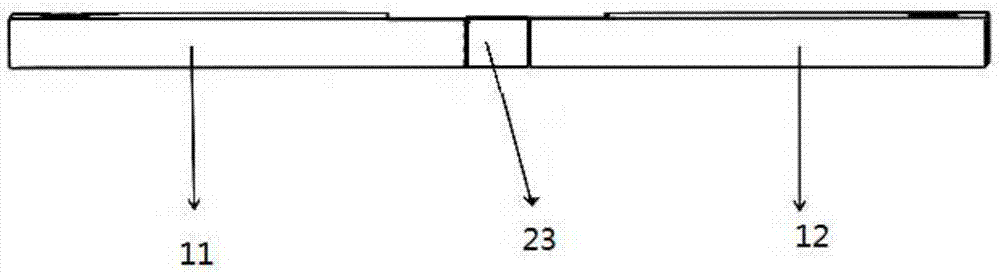

[0026] like Figure 1-6 As shown, the lithium battery module connection structure with self-protection function of this embodiment includes a plurality of battery modules 1, and the plurality of battery modules 1 are connected in series through a conductive structure 2, and the conductive structure 2 includes a first conductive copper The bar 21 and the second conductive copper bar 22, the first conductive copper bar 21 and the second conductive copper bar 22 are at the same level and the ends of the first conductive copper bar 21 and the second conductive copper bar 22 are oppositely arranged. One end of the first conductive copper bar 21 is connected to one end of the second conductive copper bar 22 through the fusible metal block 23, and the other ends of the first conductive copper bar 21 and the second conductive copper bar 22 are connected to the adjacent battery modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com