Phase shifter

A phase shifter and connecting part technology, applied in the field of phase shifters, can solve the problems of affecting the electrical performance indicators of communication networks, stress failure of threaded assemblies, unstable phase shifter functions, etc., to achieve stable and reliable welding performance and avoid interference. , The effect of reducing the installation process and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

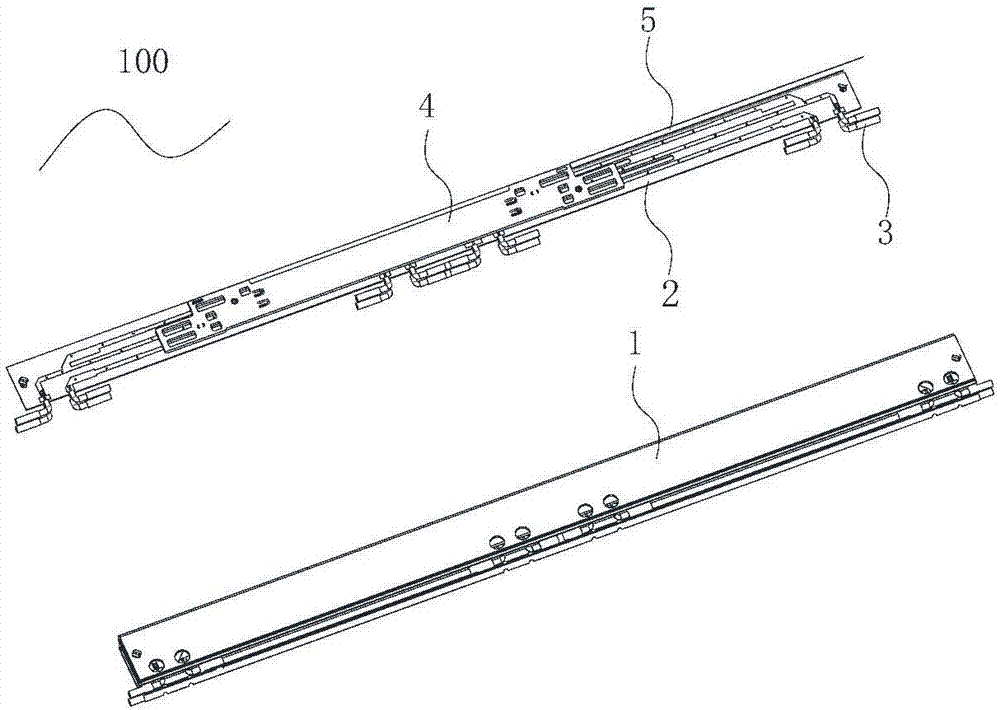

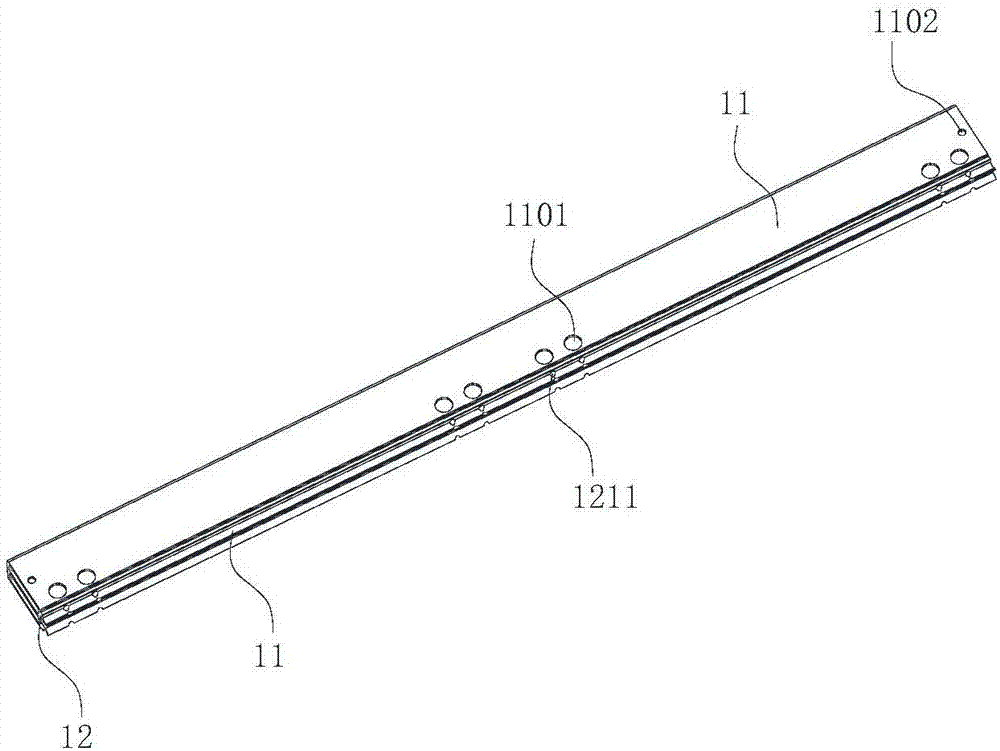

[0037] refer to Figure 1 to Figure 3 , the present invention provides a phase shifter 100, including a metal cavity 1, a PCB board 2, a coaxial cable 3, a dielectric phase shifter 4, a tie rod 5 and a positioning column 6.

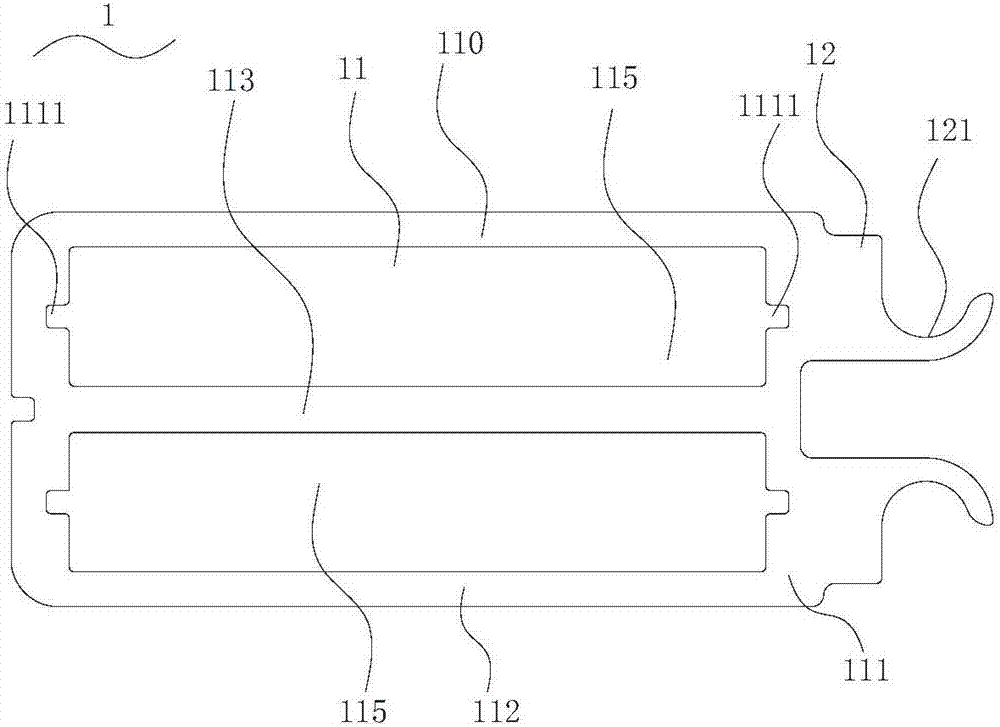

[0038] The metal cavity 1 includes a cavity body 11 and a connecting portion 12, and the cavity body 11 and the connecting portion 12 are integrally formed. The cavity body 11 includes a bottom wall 112 , a pair of side walls 111 extending upward along both sides of the bottom wall 112 in a longitudinal direction, and a top wall 110 straddling the pair of side walls 111 . The metal cavity 1 is open at both ends laterally to accommodate the PCB board 2 , the coaxial cable 3 , the dielectric phase shifter 4 and the tie rod 5 .

[0039] In this embodiment, the cavity body 11 is divided into two independent upper and lower chambers 115 by the partition plate 113 in the longitudinal direction. Corresponding to each independent chamber, a pair of side walls 1...

Embodiment 2

[0051] refer to Figure 9 The difference between the metal cavity 1a of this embodiment and the metal cavity 1 of the above-mentioned first embodiment is that in this embodiment, the outer sides of the pair of side walls 111a of the metal cavity 1a are provided with corresponding two independent cavities. In the two connecting parts 12a of the chamber 115a, the openings of the semi-arc grooves 121a on the two connecting parts 12a outside the same side wall 111a are oppositely arranged, and the opening of the semi-arc grooves at the upper connecting part is upward, and the opening of the lower one is upward. The opening of the semicircular arc groove of the connecting part is downward.

[0052] In this embodiment, during welding, the heating source can be placed between the upper and lower half-arc grooves, which can heat the upper and lower half-arc grooves at the same time, and weld the upper and lower coaxial cables at the same time, effectively improving the welding efficie...

Embodiment 3

[0054] refer to Figure 10 The difference between the metal cavity 1b of this embodiment and the metal cavity 1 of the above-mentioned first embodiment is that in this embodiment, the metal cavity 1b is provided with two independent The openings of the two connecting portions 12b of the chamber 115b and the semicircular arc grooves 121b on the two connecting portions 12b are all upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com