Bearing type welding dust collecting device

A dust collection device, knapsack technology, which is applied in the field of knapsack welding dust collection device, can solve the problems of harmful smoke or gas pollution in the workshop, the inability to weld anytime and anywhere, and harming the physical and mental health of operators, etc., achieving simple structure and low cost. The effect of low and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

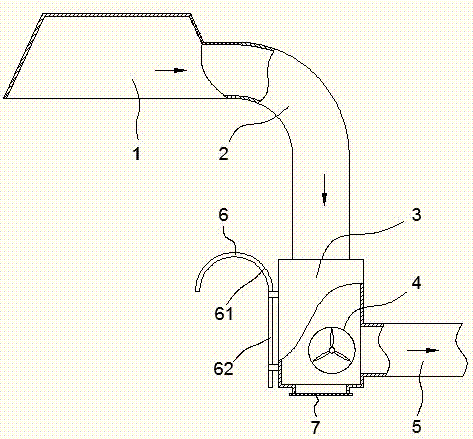

[0019] see figure 1 , a kind of piggyback welding dust collection device provided by the present invention comprises a dust collection cover 1, a connecting elbow 2, a fan box 3, a dust exhaust fan 4, a dust exhaust pipe 5 and a carrying mechanism 6, and the connecting elbow 2 One end is connected to the dust collection cover 1, and the other end is connected to the top of the fan box 3, the dust exhaust fan 4 is fixedly arranged inside the fan box 3, one side of the fan box 3 is connected to the dust discharge pipe 5, and the The side of the fan box 3 facing the dust collection hood 1 is fixedly provided with a carrying mechanism 6, and the dust collection hood 1, the connecting elbow 2, the fan box 3, and the dust discharge pipe 5 form a dust discharge channel.

[0020] The carrying mechanism 6 is a pair of hook-shaped devices that can be correspondingly hung on the shoulders of the operator, and the hook-shaped devices are integrally composed of a semicircular portion 61 an...

Embodiment 2

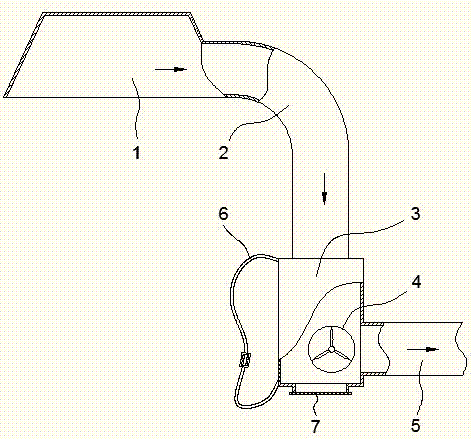

[0025] see figure 2 , a backpack type welding dust collection device provided by the present invention, the figure 1 The middle carrying mechanism 6 is improved into a double shoulder strap, and the two ends of the double shoulder strap are respectively fixed on the top and the bottom of the fan box 3, and the rest are the same as in the first embodiment.

[0026] Working principle: When using the backpack type welding dust collection device for welding operations, first put the carrying mechanism 6 of the shoulder strap on the shoulders, and then start the dust exhaust fan 4, and the harmful fume generated by welding will be sucked into the dust collection cover 1, Connect the elbow pipe 2, the fan box 3, and the dust discharge pipe 5, wherein the dust discharge pipe 5 can be lengthened and connected to the centralized flue gas dust removal device fixed in the factory building, so as to achieve the purpose of quickly processing harmful welding fumes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com