Plastic multi-color automatic integrated production equipment and method

A production equipment and plastic technology, applied in the field of plastic multi-color automatic integrated production equipment, can solve the problems of difficult to achieve mass production and processing of products, unfavorable processing costs, low work efficiency, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

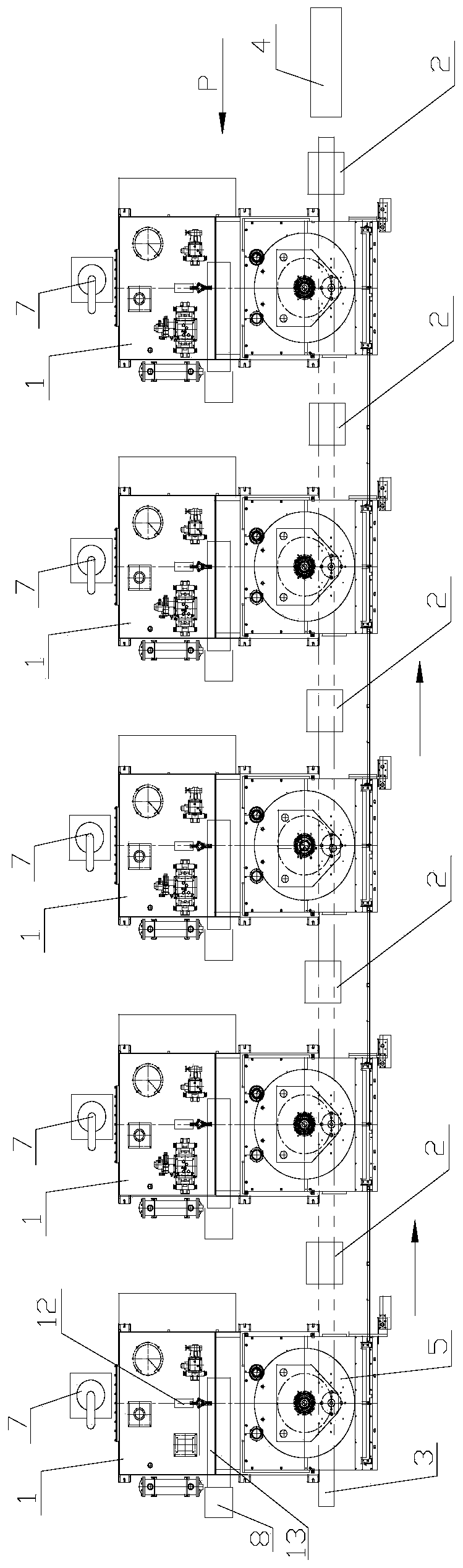

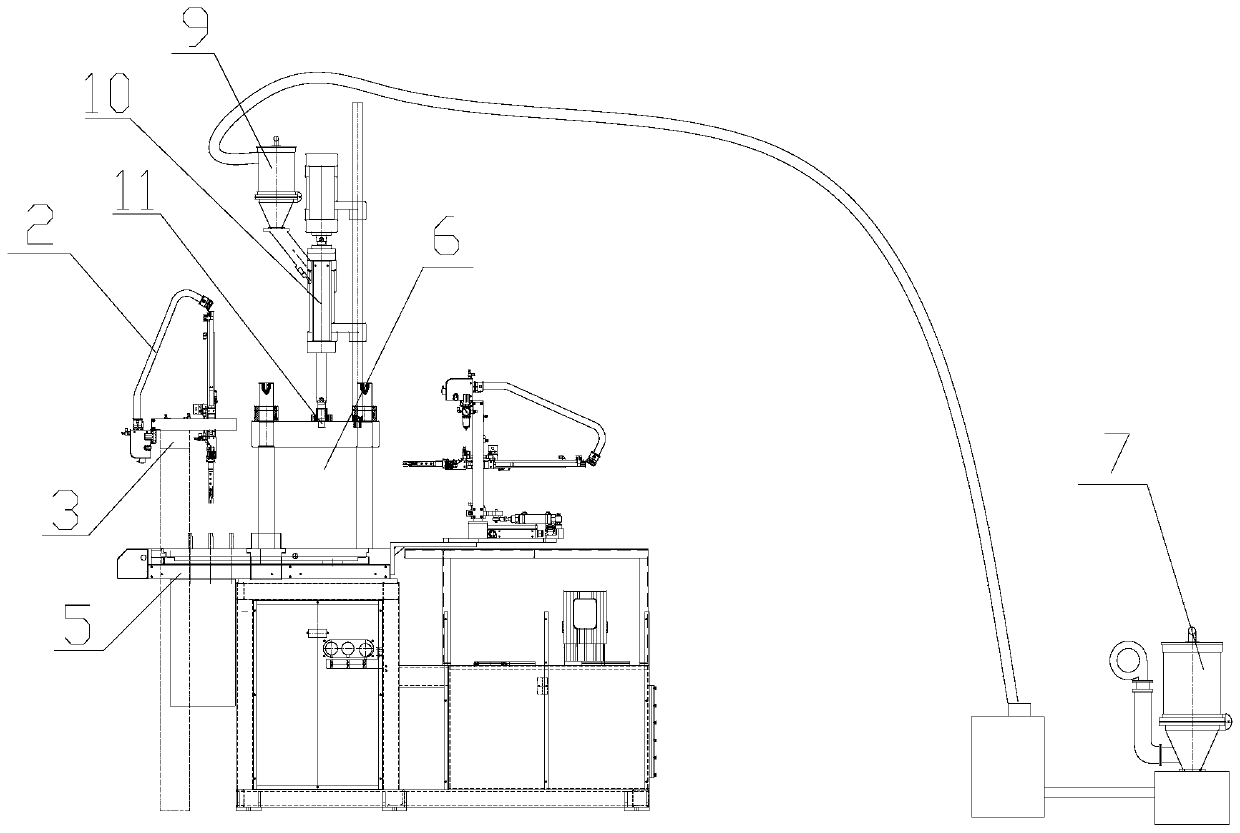

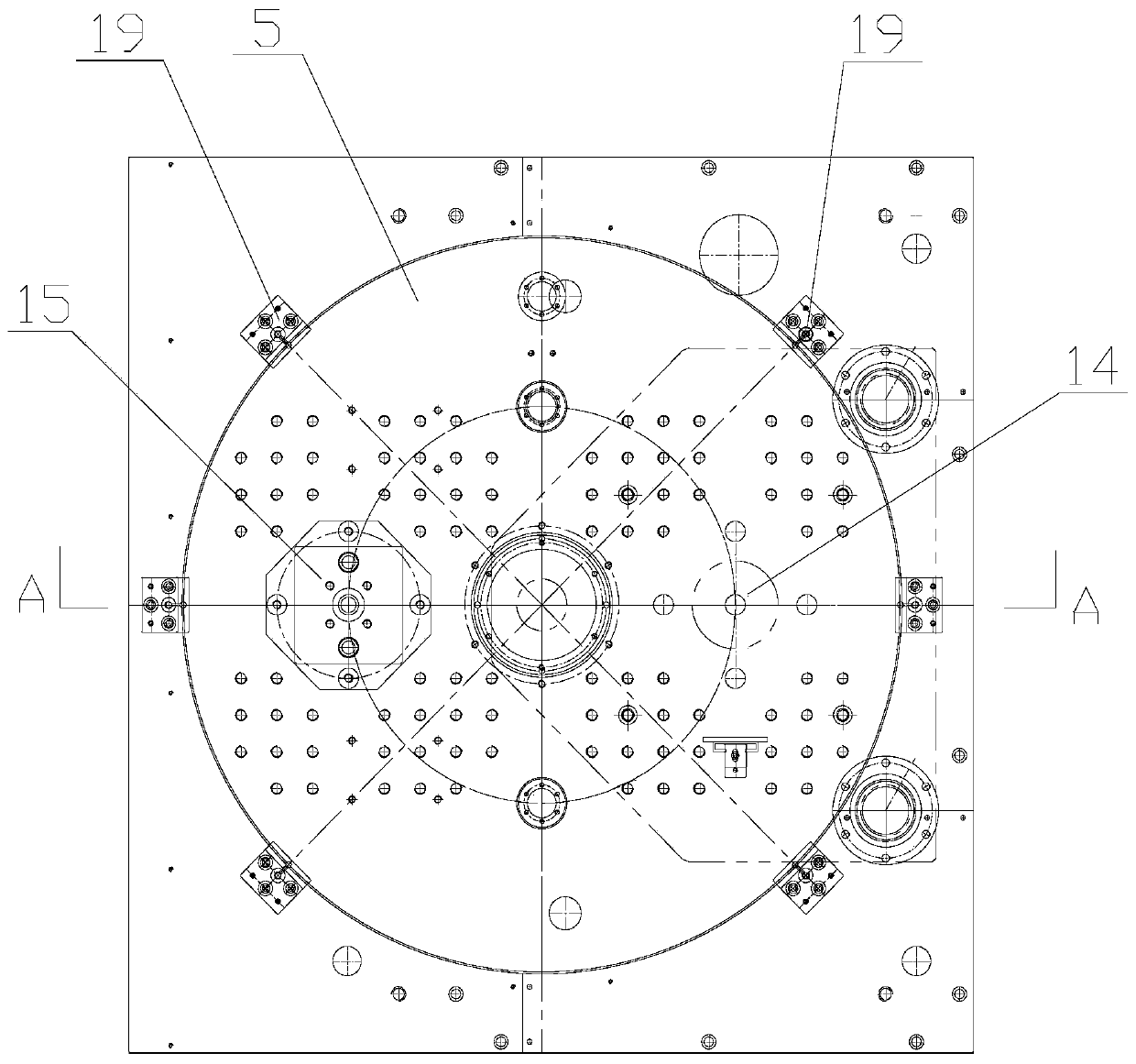

[0030] In this embodiment, a kind of plastic multi-color automatic integrated production equipment, such as figure 1 As shown, it includes multiple injection molding machines 1, multiple beam manipulators 2, manipulator installation guide rails 3 and product output conveyor belt 4, multiple injection molding machines are distributed side by side, and the manipulator installation guide rails are continuously arranged on one side of each injection molding machine; according to the product In the conveying direction, the end of the manipulator installation guide rail is equipped with a product output conveyor belt, and the output end of each injection molding machine is equipped with a beam manipulator, and the product is sent to the next adjacent injection molding machine or product output conveyor belt through the beam manipulator , each beam manipulator is respectively set on the manipulator installation guide rail and moves left and right along the manipulator installation gui...

Embodiment 2

[0041] In this embodiment, a plastic multi-color automatic integrated production method is realized through the equipment described in Embodiment 1: multiple injection molding machines are arranged in sequence according to the conveying direction of the product, the product is a multi-color plastic product, and the first injection molding machine molds the product. After the part of one color is taken out by the first beam manipulator and sent to the second injection molding machine; the second injection molding machine performs injection molding of the second color part on the basis of the first color part, and after completion, the second beam manipulator Take it out and send it to the third injection molding machine for injection molding processing, until the last injection molding machine completes the injection molding of the last color part of the product, the last beam manipulator will take out the product and send it to the product output conveyor belt;

[0042] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com