A method for continuous carbonization to produce calcium carbonate with controllable particle size

A calcium carbonate, particle size technology, applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of irregular morphology, strong agglomeration, incomplete particle development, etc. effects, fast blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

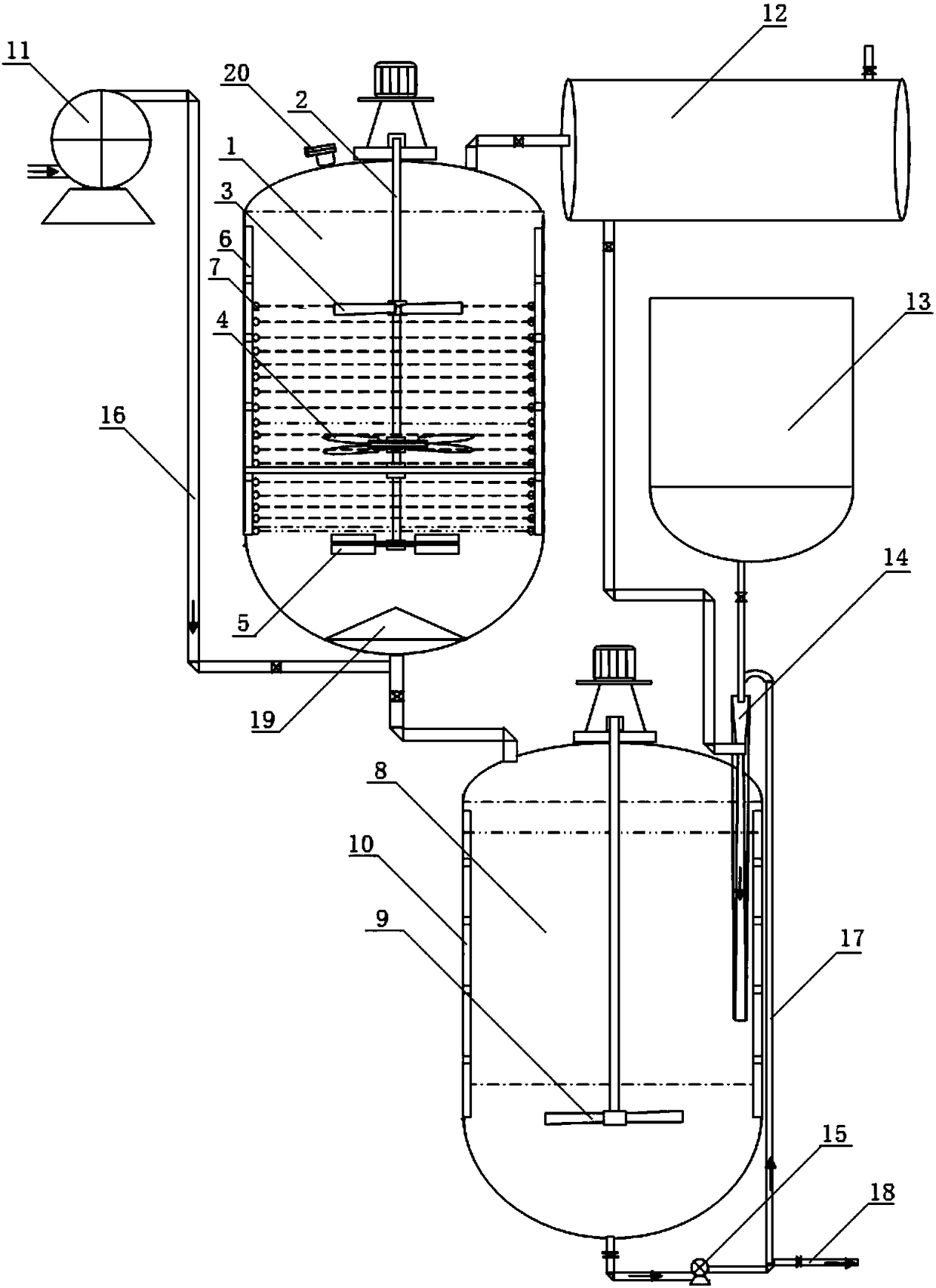

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] Embodiments of the present invention, a method for continuous carbonization to produce particle size controllable calcium carbonate, the following device is used: as figure 1 As shown, it includes a water ring air compressor 11, a primary carbonization tower 1, a gas distributor 19, a primary carbonization stirring device, a gas storage tank 12, a secondary carbonization tower 8, a secondary carbonization stirring device 9, a circulating emulsification pump 15, a hydrogen Calcium oxide storage tank 13, Venturi injector 14 and other mechanisms. The gas distributor 19 is arranged in the primary carbonization tower 1 and is located at the bottom of the primary carbonization tower 1, the water ring air compressor 11 is connected with the gas distributor 19 through the inlet pipe 16, and the primary carbonization stirring device is arranged i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com