Clearance eliminating device for gear pair

A technology of gear pair and clearance, applied in the direction of transmission parts, belt/chain/gear, mechanical equipment, etc., can solve the problems of inability to automatically compensate, unstable spring preload, inconvenient adjustment, etc., to reduce cutting chatter. Vibration and transmission error, solve the lack of spring force stiffness, solve the effect of inconvenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

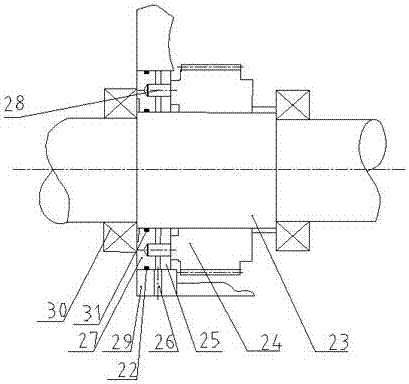

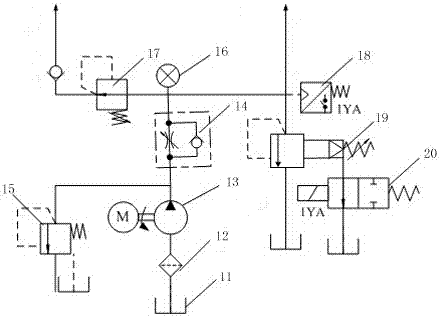

[0020] Embodiment one: see figure 1 and image 3 A gear pair backlash elimination device of the present invention includes a transmission shaft 24, a driven gear 23 fixedly arranged on the transmission shaft 24, and a hydraulic system, and the left side of the driven gear 23 is sequentially provided with a friction damping disc 25 and a Back cover two 27, an oil chamber is arranged between the friction damping disc two 25 and the back cover two 27, and the outer peripheral wall of the friction damping disc two 25 and the back cover two 27 is sleeved with a gear box body two 29. The gear box body 2 29 is provided with an oil port 26 connected to the oil chamber. When the pressure oil enters the oil chamber between the rear cover 27 and the friction damping disc 25 through the oil port 26, the friction The second damping disc 25 is subjected to a constant pressure from the pressure oil to the right, and the right end surface of the friction damping disc 25 is tightly attached t...

Embodiment 2

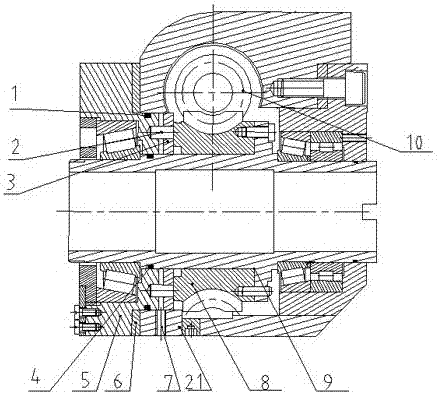

[0031] Embodiment two, see figure 2 and image 3 , a gear pair backlash elimination device of the present invention, comprising a worm gear shaft 9, a worm gear 8 fixedly arranged on the worm gear shaft 9, a worm screw 10 arranged above the worm gear 8 and meshed with the worm gear, and a hydraulic system, the worm gear 8 Friction damping disc-3 and rear cover-5 are arranged in sequence on the left side of the left side, an oil cavity is arranged between the friction damping disc-3 and rear cover-5, and the friction damping disc-3 and rear cover-5 The outer peripheral wall of the casing is provided with a gear box body-21, and the gear box body-21 is provided with an oil port-7 connected to the oil chamber. When the pressure oil enters the back cover-5 from the oil port-7 and friction Behind the oil chamber between the damping disc-3, the friction damping disc-3 is subjected to a constant pressure from the pressure oil to the right, and the right end surface of the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com