A cosmetic brush and a manufacturing method thereof

A manufacturing method and technology of cosmetic brushes, applied in the direction of brushes, brush bodies, bristles, etc., can solve problems such as heat resistance of adhesives, peeling off of adhesive parts, and rising manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to fully understand the present invention and its operational advantages and objectives achieved according to the embodiments of the present invention, reference must be made to the accompanying drawings illustrating preferred embodiments of the present invention and the contents described in the accompanying drawings.

[0060] Hereinafter, the present invention will be described in detail by explaining preferred embodiments of the present invention with reference to the attached drawings. The same reference numerals are given in the various figures to designate the same parts.

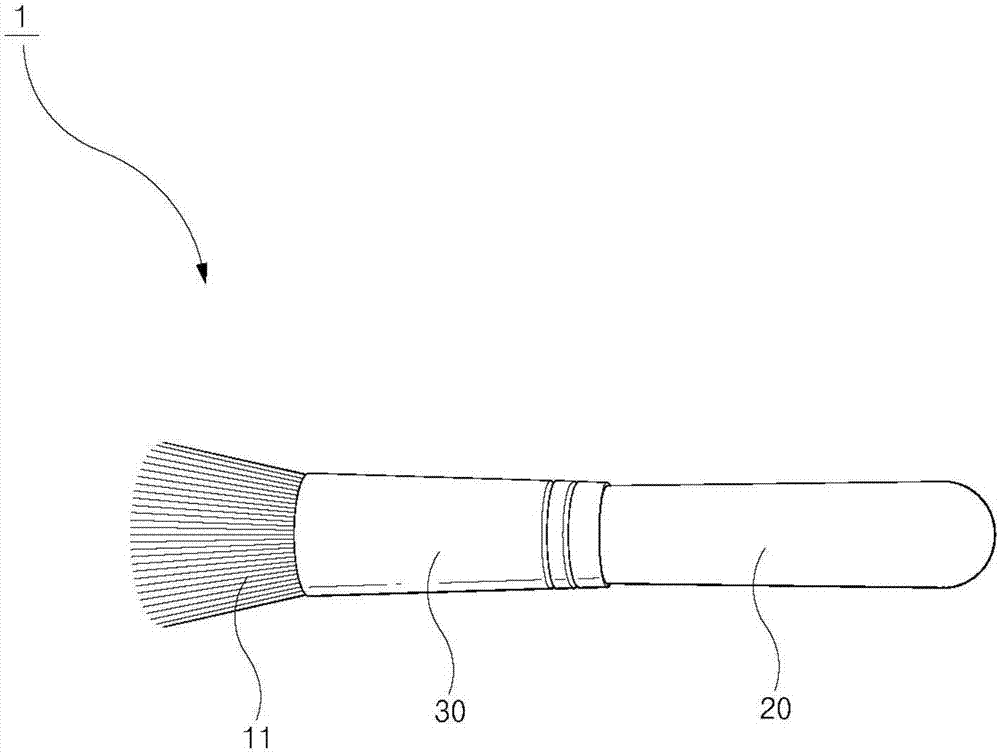

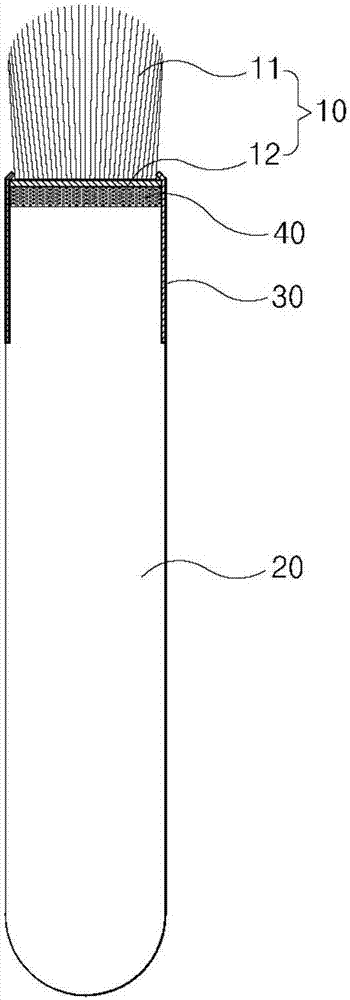

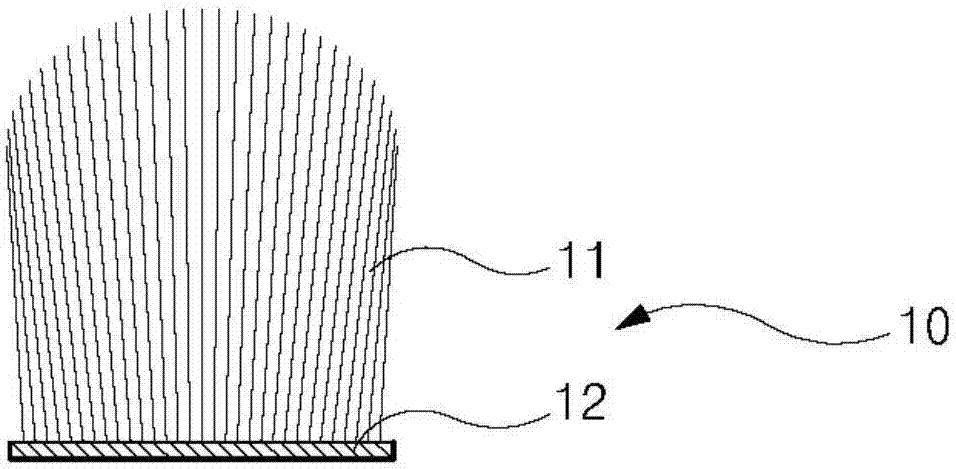

[0061] figure 1 To schematically illustrate a perspective view of a cosmetic brush according to an embodiment of the present invention, figure 2 for right figure 1 A schematic cross-sectional view of the bonded parts shown in , before pressurization, image 3 In order to use the manufacturing method of this embodiment to schematically show figure 2 The figure of the makeup brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com