Component analysis device for high polymer chemical material

A material composition and analysis device technology, applied in the field of polymer chemistry, can solve problems such as time-consuming and labor-intensive shaking, uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

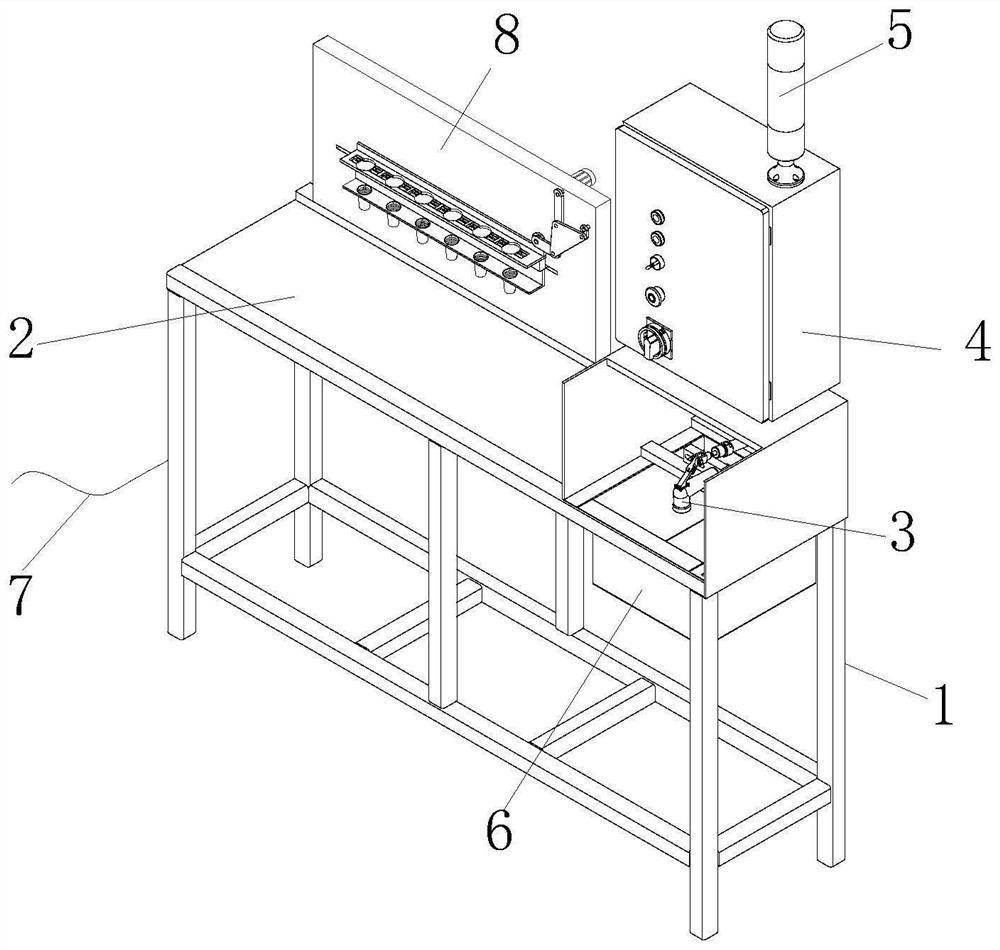

[0033] see figure 1 , the present invention provides a kind of composition analysis device for macromolecule chemical material through improvement, including support frame 1, analysis platform 2, discharge valve 3, indicator light 5, collection frame 6, power lead wire 7 and placement shaking mechanism 8, The support frame 1 is fixed to the bottom of the analysis table 2, the top of the analysis table 2 is provided with a discharge valve 3, and the shaking mechanism 8 is installed on the top of the analysis table 2, the analysis table 2 is fixed to the bottom of the control panel 4, and an indicator is installed on the top of the control panel 4 Lamp 5, analysis platform 2 are connected with the bottom of collecting frame 6, and analysis platform 2 is fixed with the right end of power lead 7.

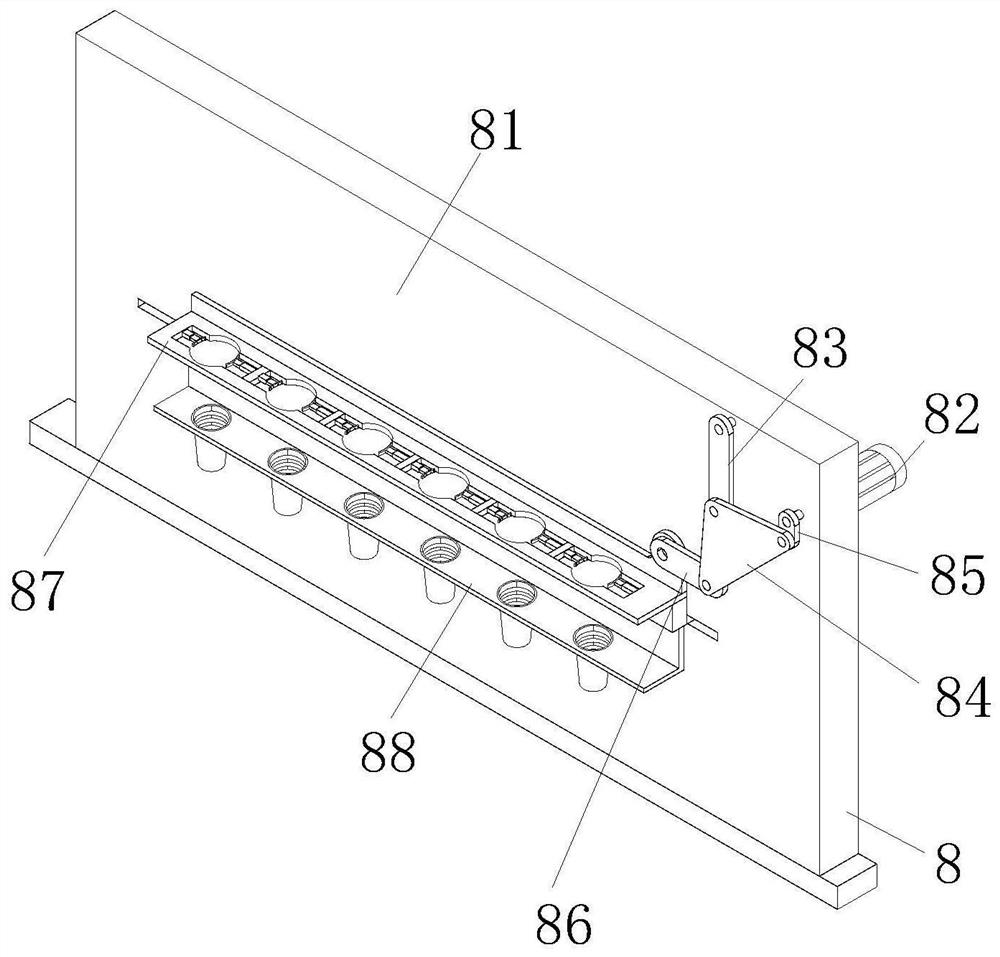

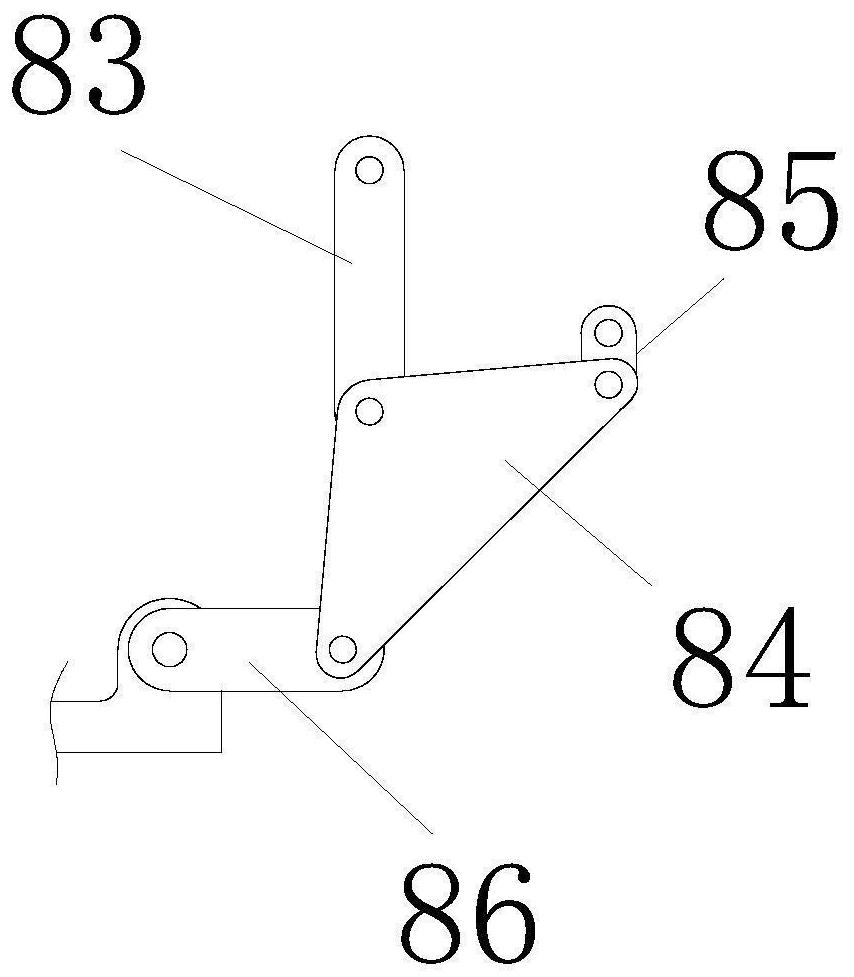

[0034] see figure 2 and image 3 , the present invention provides a kind of composition analysis device for macromolecule chemical material through improvement here, place rocking me...

Embodiment 2

[0041] The present invention provides a composition analysis device for polymer chemical materials through improvement. There are six placing grooves 874, and the placing grooves 874 and the placing pipes 884 are distributed parallel to each other and are in the same vertical direction, which is beneficial to play For placing the test tube, buffer structures 875 are provided at the left and right ends of the placement groove 874, and the cross section of the rotating block 84 is in the shape of an isosceles triangle, which is beneficial to drive the first swinging rod 83 and the second swinging rod 86 for linkage. effect.

[0042] The present invention provides a composition analysis device for polymer chemical materials through improvement, and its working principle is as follows;

[0043] First, before use, place the device used for composition analysis of polymer chemical materials horizontally, so that the support frame 1 can fix and support the device;

[0044] Second, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com