Heading joint device for elevator steel belts

A termination device, elevator steel technology, applied in belt fasteners, transportation and packaging, belts/chains/gears, etc., can solve the problems of inconvenient disassembly, unreasonable structural design, etc., to achieve convenient and quick replacement, reduce The number of dangerous points and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

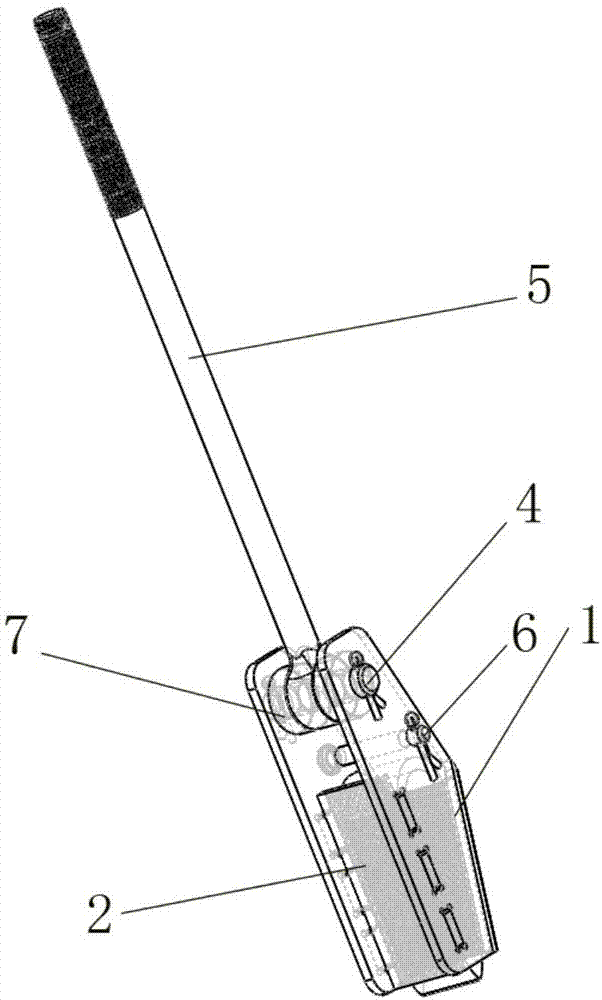

[0040] see figure 1 , the present invention proposes a terminal connection device for an elevator steel belt, which includes a taper sleeve 1, an insert plate 2, a cone core 3, a first rotating shaft 4 and a screw rod 5,

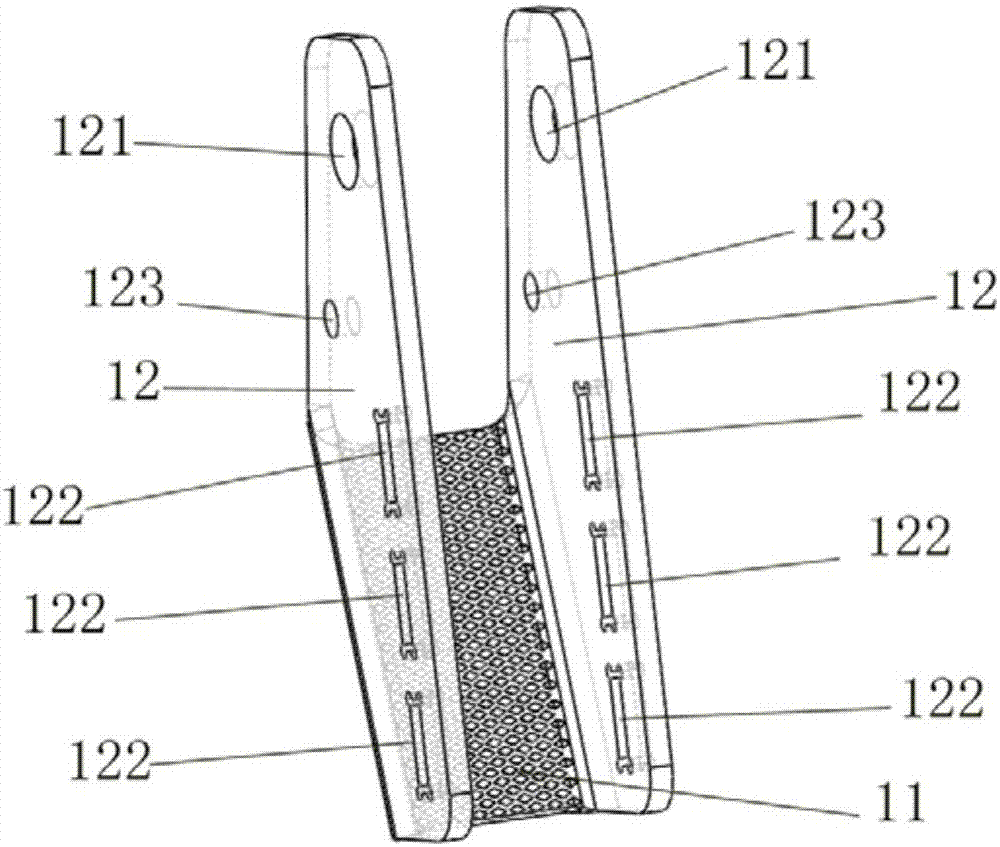

[0041] see figure 2 , the taper sleeve 1 is a groove formed by bending a V-shaped plate along the axis of symmetry, the groove is composed of a bottom plate 11 and a pair of side plates 12 parallel to each other, the inner wall of the bottom plate 11 is a rough surface, so The top of the side plate 12 is provided with a first through hole 121, and the bottom of the side plate 12 is provided with a plurality of second through holes 122, and the plurality of second through holes 122 are all along the side plate 12. arranged on the long side,

[0042] In one embodiment of the present invention, the lower part of the side plate 12 is provided with three second through holes 122, and the three second through holes 122 are arranged at equal intervals along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com