Engine assembly transporter

A technology of engine assembly and transfer device, which is applied in hoisting device, transportation and packaging, clockwork mechanism, etc., can solve the problems of high labor intensity, low production efficiency, easy bump and scratch of engine oil pan, etc., and achieve Avoid bumps and scratches, improve work efficiency, and automatically and precisely control the lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

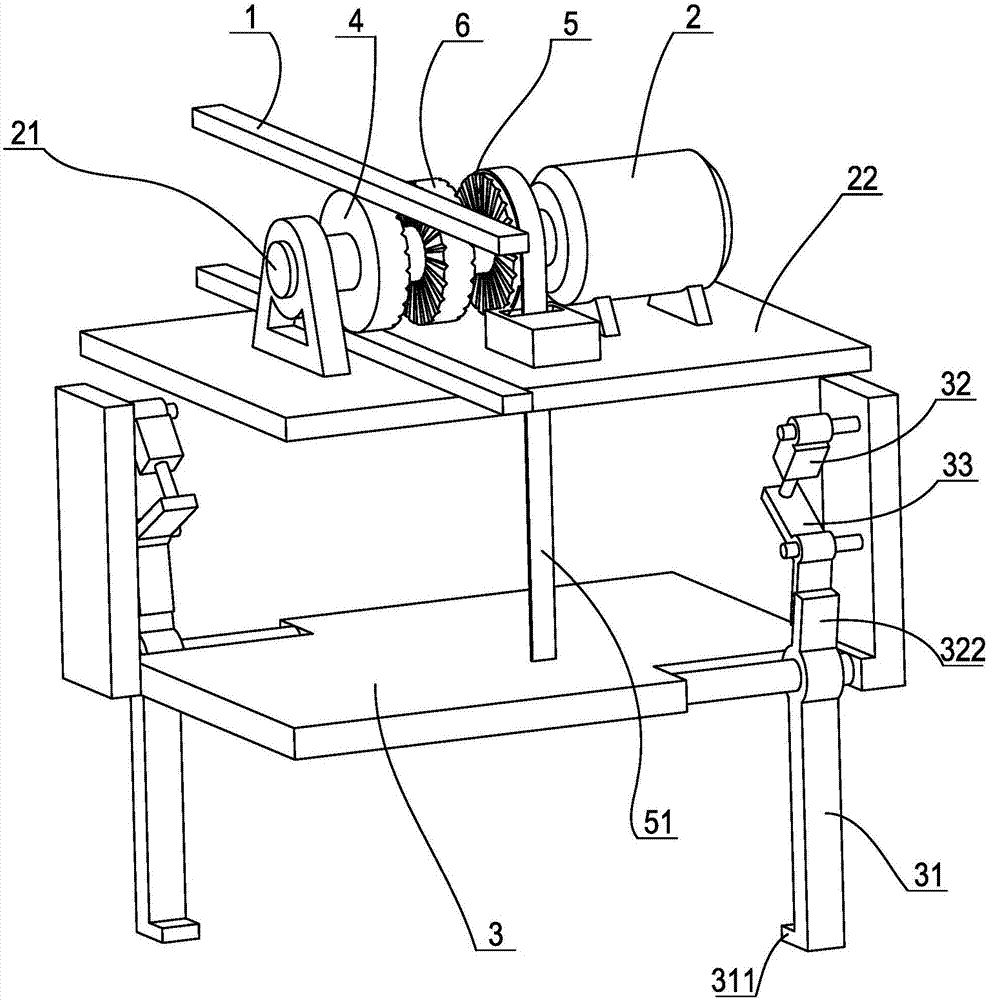

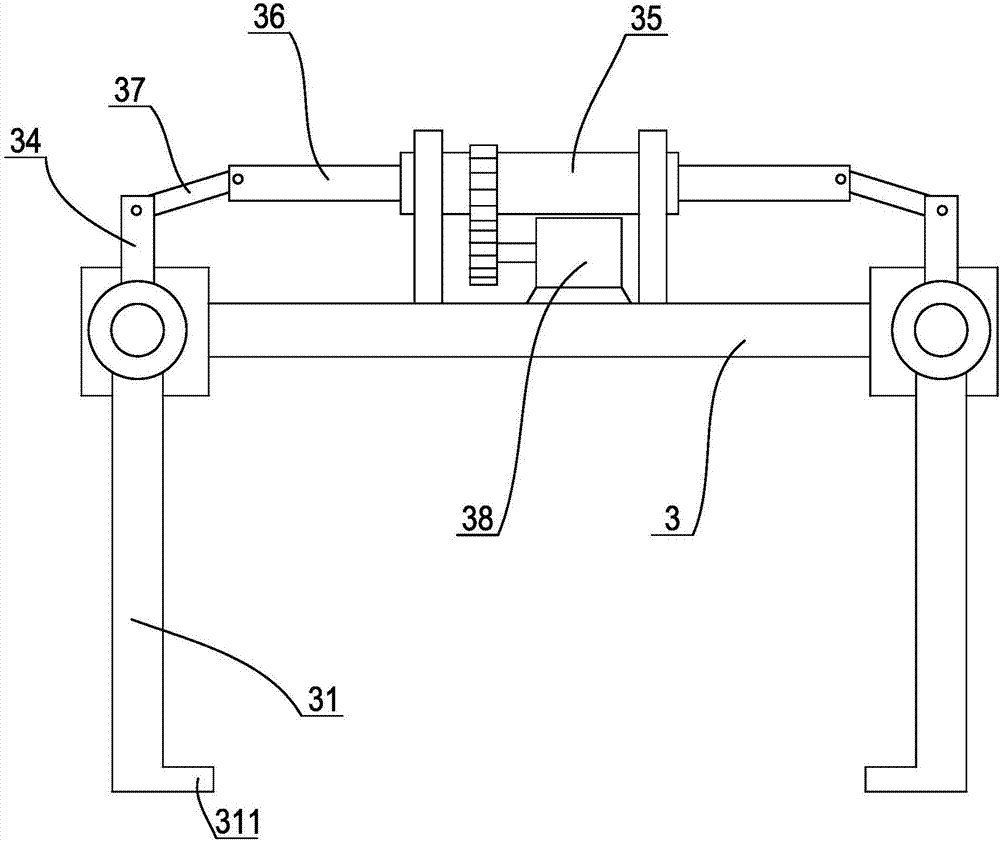

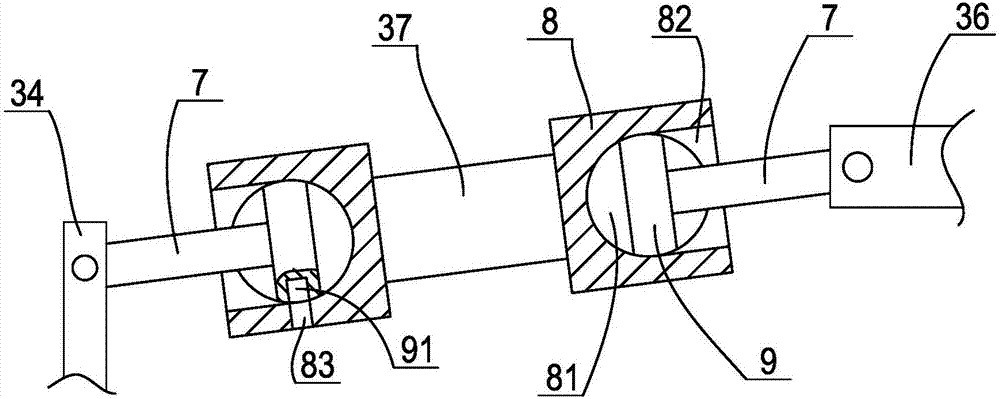

[0023] Such as figure 1 As shown, an engine assembly transfer device is suitable for transferring the sub-assembled engine assembly on the engine sub-assembly line and the front axle and engine assembly line during automobile assembly, so that the engine assembly can be transferred on the front axle and engine assembly line The front axle and the engine are assembled together. Specifically, it includes a suspension track 1 suspended in the air, and a mobile lifting mechanism movably suspended on the suspension track. The mobile lifting mechanism includes a driving motor 2, a driving shaft 21 connected to the motor shaft of the driving motor, an automatic clutch structure for selectively transmitting the power of the driving motor, and a lifting bracket 3 located below the driving motor. In order to facilitate installation, we can fix the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com