A kind of rubber composition, rubber product, hydraulic hose and preparation method thereof

A rubber composition and rubber hose technology, applied in the direction of pipes, hoses, mechanical equipment, etc., can solve the problems such as the performance decline of the inner lining, low oil resistance and temperature resistance, restricted use, etc., to improve the aging resistance and liquid resistance. properties, excellent oil and temperature resistance, and the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] There are three main preparation methods of HNBR: ethylene-acrylonitrile copolymerization method, NBR solution hydrogenation method and NBR emulsion hydrogenation method.

[0080] Hydrogenated nitrile rubber raw rubber is commercially available.

[0081] (II) Compounding agent

[0082] (1) Thermal carbon black

[0083] Thermal cracking carbon black is produced by pyrolysis of natural gas isolated from air and heated to high temperature (for example, 1300°C). It is composed of a large number of spherical and elliptical carbons and a small amount of welded particles. It has large particle size, small specific surface area, low structure, easy dispersion and flow. Good performance, high filling capacity and so on. Because of its low surface activity, it is also called non-reinforcing carbon black. It is one of the widely used carbon black varieties in tire inner liners, rubber hoses, tapes, oil seals, and fluorine rubber products.

[0084] According to one embodiment, t...

Embodiment approach

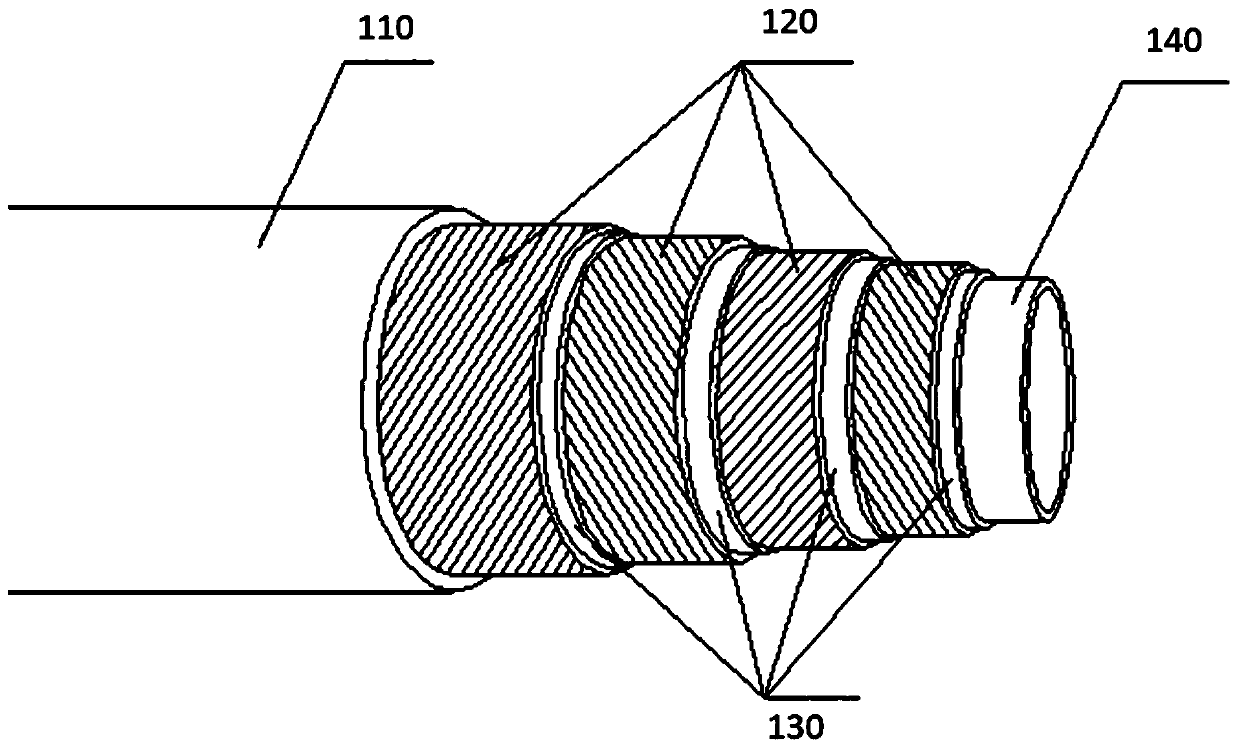

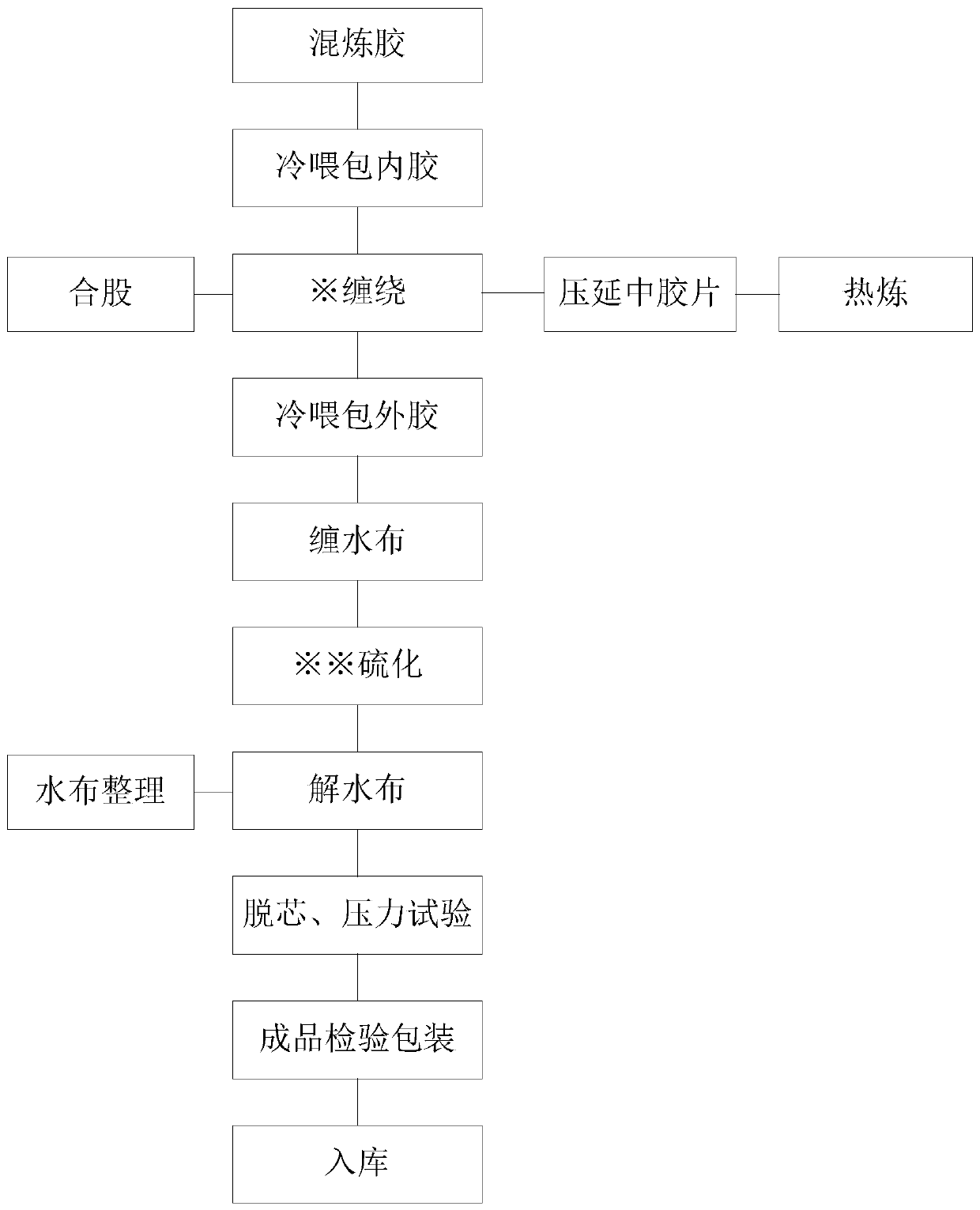

[0168] The invention also relates to a method for preparing the hydraulic rubber hose. According to one embodiment, the hydraulic hose preparation method includes the following steps:

[0169] (a) extrude the inner rubber layer using the mixed rubber of the present invention;

[0170] (b) preparing the middle rubber layer, the reinforcement layer, and the outer rubber layer; and

[0171] (c) vulcanization.

[0172] According to one embodiment, the method for preparing a hydraulic rubber hose includes: using the compounded rubber of the present invention to extrude the inner rubber layer (inner lining layer), through the reinforced layer (preferably wound steel wire reinforced layer), extruding the outer coating layer, coating and shaping, Vulcanization, manufacturing hydraulic hoses (especially steel wire wound hydraulic hoses).

[0173] The present invention also relates to a hydraulic rubber hose prepared by using the rubber compound of the present invention as an inner r...

Embodiment

[0184] 1. Mixed rubber components and dosage (unit: parts by mass)

[0185] 1. Raw materials

[0186] Table 1 Raw materials

[0187] serial number

raw material

Raw material supplier

1

hydrogenated nitrile rubber

LANXESS

2

Nitrile rubber 6280

Korea LG

3

Zinc oxide

Shijiazhuang Longhao Chemical Group Co., Ltd.

4

stearic acid

Rugao Shuangma Chemical Co., Ltd.

5

Antiager 445

Jiangsu Haian Petrochemical Plant

6

Antiager MB

Jiangsu Haian Petrochemical Plant

7

Carbon black N990

Tianjin Jinqiushi Chemical Co., Ltd.

8

Carbon black N550

Cabot

9

Liquid nitrile rubber (softener)

Lanzhou Petrochemical

10

accelerator DM

Hebei Yanbang Chemical Technology Co., Ltd.

11

vulcanizing agent sulfur

Linyi Jinsulfon Chemical Co., Ltd.

12

Vulcanizing agent HVA-2

Taizhou Huangyan Donghai Chemical Co., Ltd.

13

Vu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap