Optical imaging system

An optical imaging system, imaging surface technology, applied in optics, optical components, instruments, etc., can solve problems such as total length and general imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

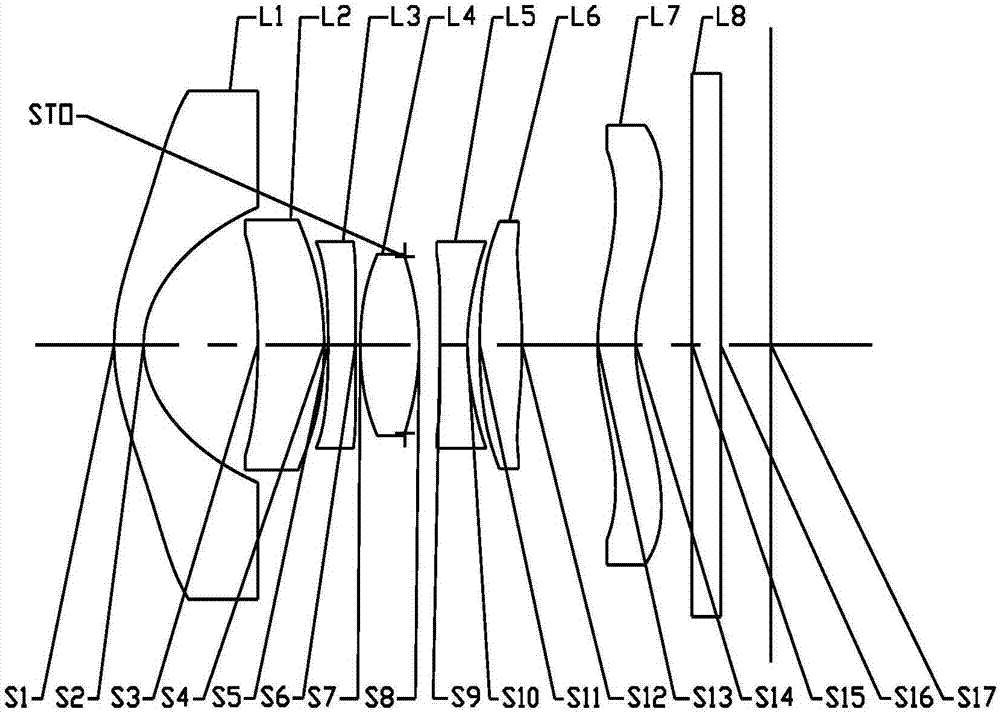

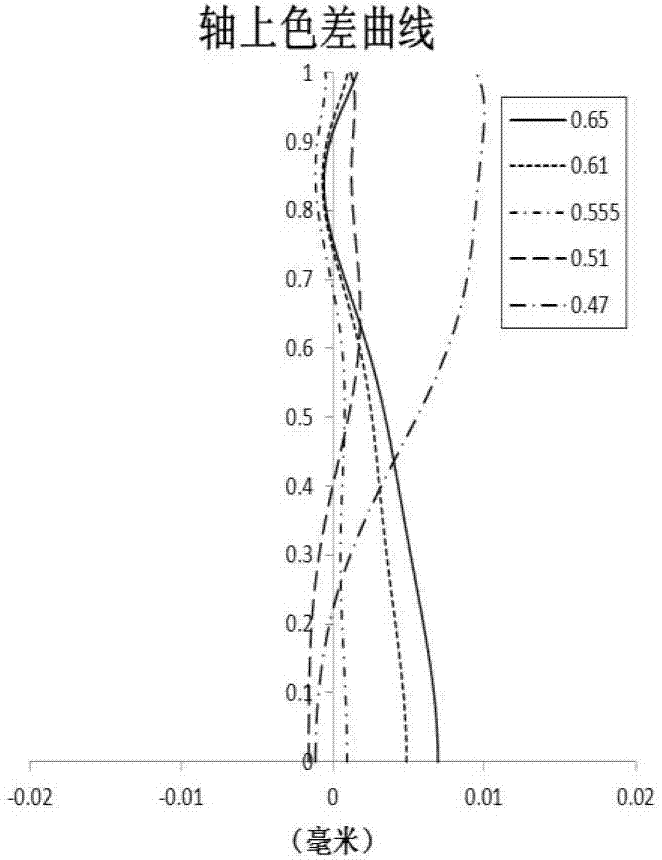

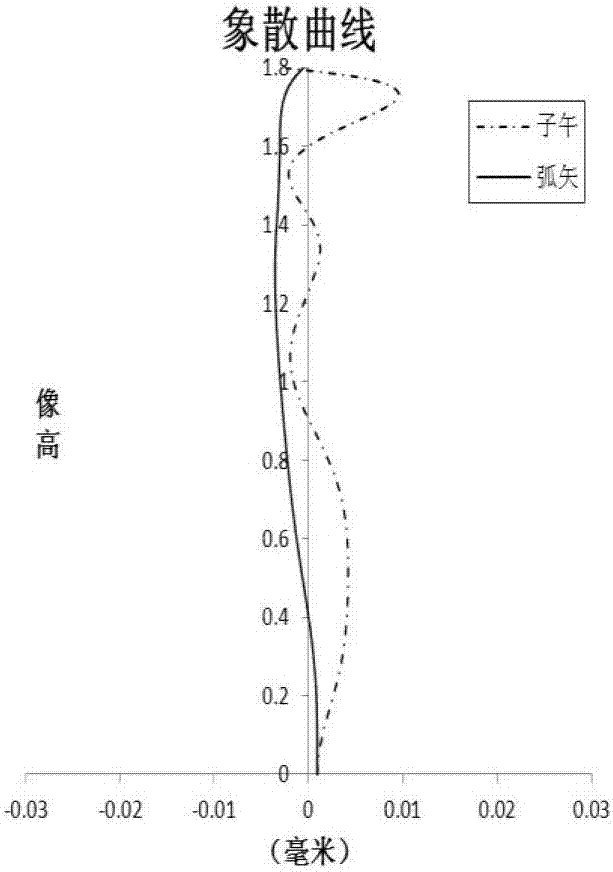

[0068] Refer to the following Figure 1 to Figure 2D An optical imaging system according to Embodiment 1 of the present application is described.

[0069] figure 1 A schematic structural diagram of an optical imaging system according to Embodiment 1 of the present application is shown. Such as figure 1 As shown, the optical imaging system includes seven lenses L1-L7 arranged in sequence from the object side to the imaging side along the optical axis. The first lens L1 has an object side S1 and an image side S2; the second lens L2 has an object side S3 and an image side S4; the third lens L3 has an object side S5 and an image side S6; the fourth lens L4 has an object side S7 and an image side S8; the fifth lens L5 has an object side S9 and an image side S10; the sixth lens L6 has an object side S11 and an image side S12; and the seventh lens L7 has an object side S13 and an image side S14.

[0070] In this embodiment, the first lens may have negative power with a concave im...

Embodiment 2

[0087] Refer to the following Figure 3 to Figure 4D An optical imaging system according to Embodiment 2 of the present application is described. In addition to the parameters of each lens of the optical imaging system, such as the radius of curvature, thickness, conic coefficient, effective focal length, axial distance, and high-order coefficients of each mirror surface of each lens, in the second embodiment and below The arrangement structure of the optical imaging system described in each embodiment is the same as that of the optical imaging system described in Embodiment 1. For the sake of brevity, part of the description similar to Embodiment 1 will be omitted.

[0088] image 3 A schematic structural diagram of an optical imaging system according to Embodiment 2 of the present application is shown. Such as image 3 As shown, the optical imaging system according to Embodiment 2 includes first to seventh lenses L1-L7 respectively having an object side surface and an im...

Embodiment 3

[0098] Refer to the following Figure 5 to Figure 6D An optical imaging system according to Embodiment 3 of the present application is described.

[0099] Figure 5 A schematic structural diagram of an optical imaging system according to Embodiment 3 of the present application is shown. Such as Figure 5 As shown, the optical imaging system according to Embodiment 3 includes first to seventh lenses L1-L7 respectively having an object side and an image side. Table 7 shows the surface type, curvature radius, thickness, material and conic coefficient of each lens of the optical imaging system of Embodiment 3. Table 8 shows the higher-order term coefficients of each aspheric mirror surface in Example 3. Table 9 shows the effective focal length f1 to f7 of each lens of embodiment 3, the effective focal length f of the imaging lens of the optical imaging system, the distance between the object side S1 of the first lens L1 and the imaging surface S17 of the optical imaging system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com