Magnetic one-component powdered ink and preparation method thereof

A single-component, toner technology, applied in the printing field, can solve problems such as low density, burrs, and insufficient charging of toner, and achieve the effects of stable charge distribution, stable image density, and no burrs in writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

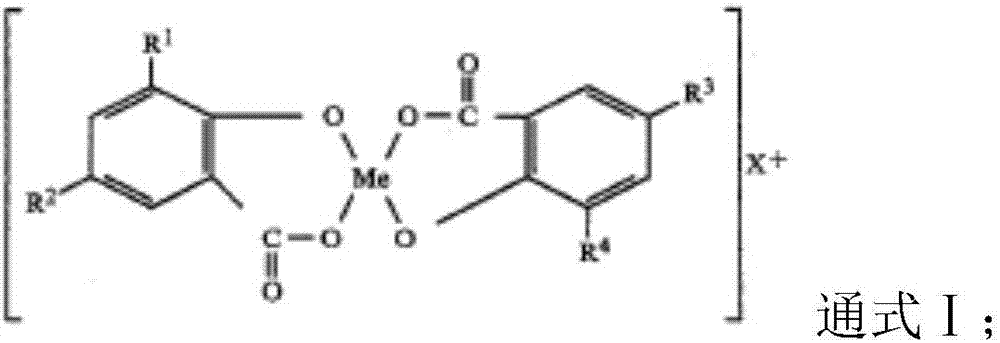

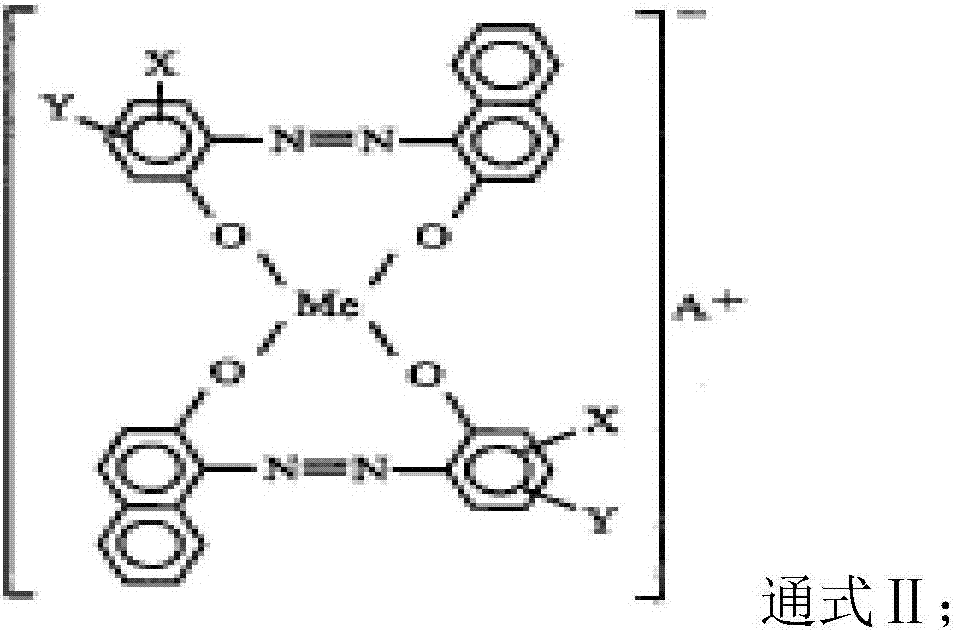

Method used

Image

Examples

Embodiment 1~3

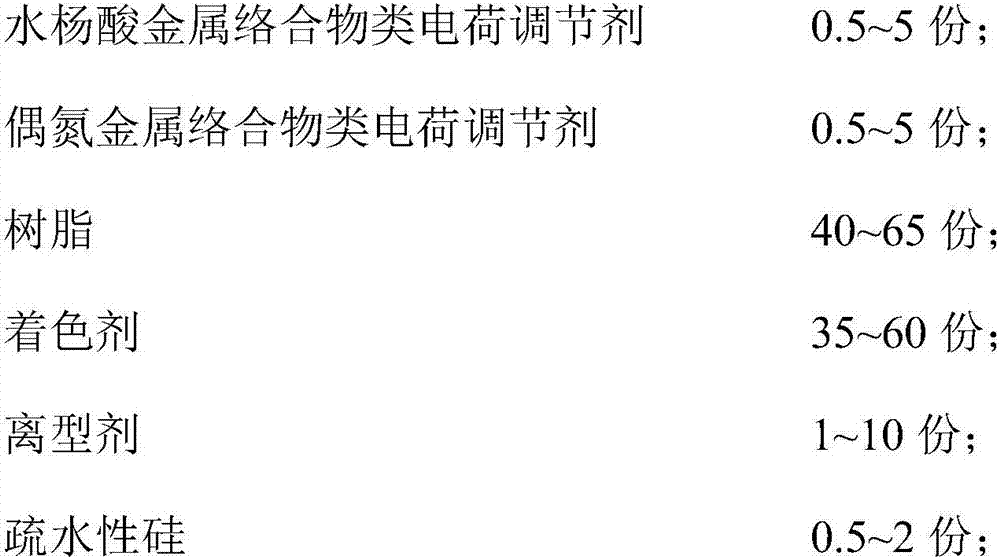

[0066] The components of embodiment 1~3 are as shown in table 2:

[0067] Components of Table 2 Embodiment 1~3

[0068]

[0069]

[0070] Embodiment 1~3 is tested by the test method in comparative example:

[0071] The initial printing density of Example 1 was 1.282, and the density after printing 3000 sheets was 1.354. There is no glitch in the printing process.

[0072] The initial printing density of Example 2 was 1.257, and the density after printing 3000 sheets was 1.303. There is no glitch in the printing process.

[0073] The initial printing density of Example 3 was 1.202, and the density after printing 3000 sheets was 1.312. There is no glitch in the printing process.

[0074] From the test results of Examples 1 to 3, it can be seen that the image density of the examples is higher than that of the comparative example 1, and the high density can still be maintained after 3000 images.

[0075] The source of composition of comparative example and embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com