Novel toner and preparation technology thereof

A preparation process and toner technology, which is applied in the field of new toner and its preparation process, can solve the problems of bottom ash, low waste powder rate, toner flying powder, low consumption, etc., and achieve good fluidity, The effect of low consumption and low waste powder rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention provides a preparation process of a novel toner, which includes the following steps:

[0024] S1. Prepare toner matrix particles by using binder emulsion, colorant dispersion and release agent dispersion.

[0025] The used binder of preparation toner can use any conventional toner resin, and suitable binder can enumerate and include for example thermoplastic resin and polyester, and thermoplastic resin is usually vinyl resin, especially styrene resin, Suitable thermoplastic resins comprise polymeric esters selected from at least styrene methacrylates, polyolefins, styrene acrylates, cross-linked styrene polymers, epoxies, polyurethanes, vinyl resins, dicarboxylic acids and glycols At least one of the group consisting of compounds.

[0026] The release agent (wax) used to prepare the toner comprises at least one selected from low molecular weight polyethylene wax, maleic anhydride modified polyethylene wax, low molecular weight po...

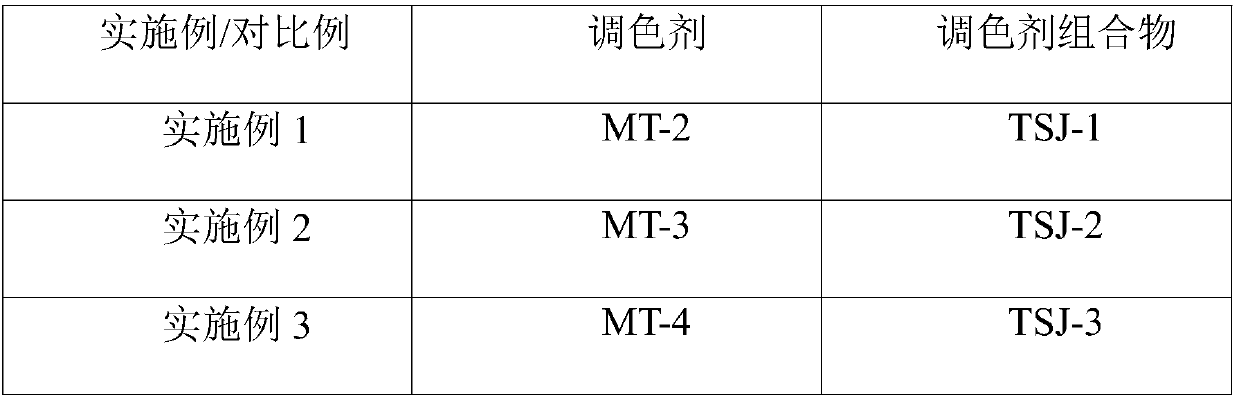

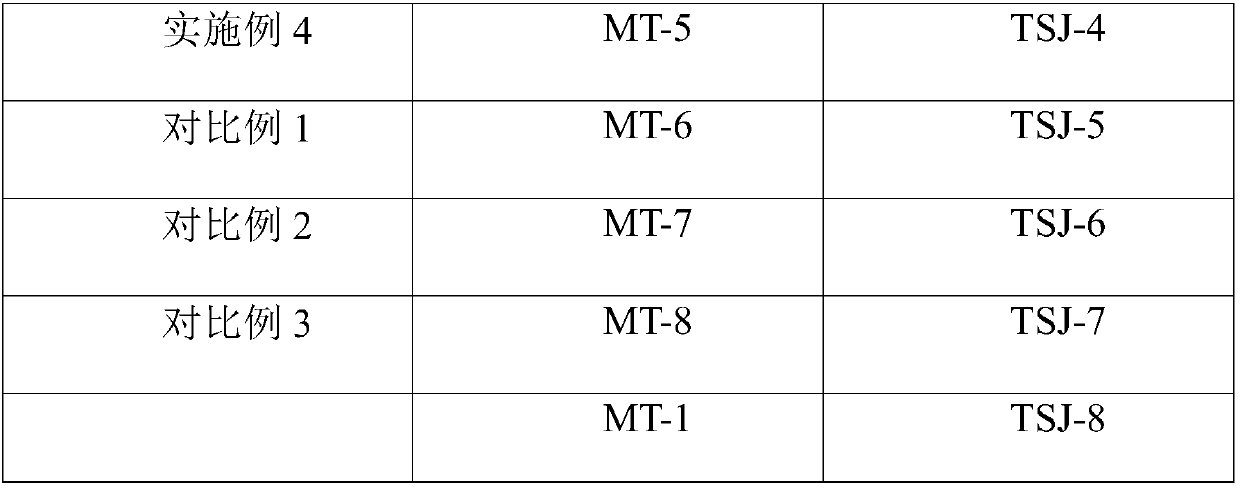

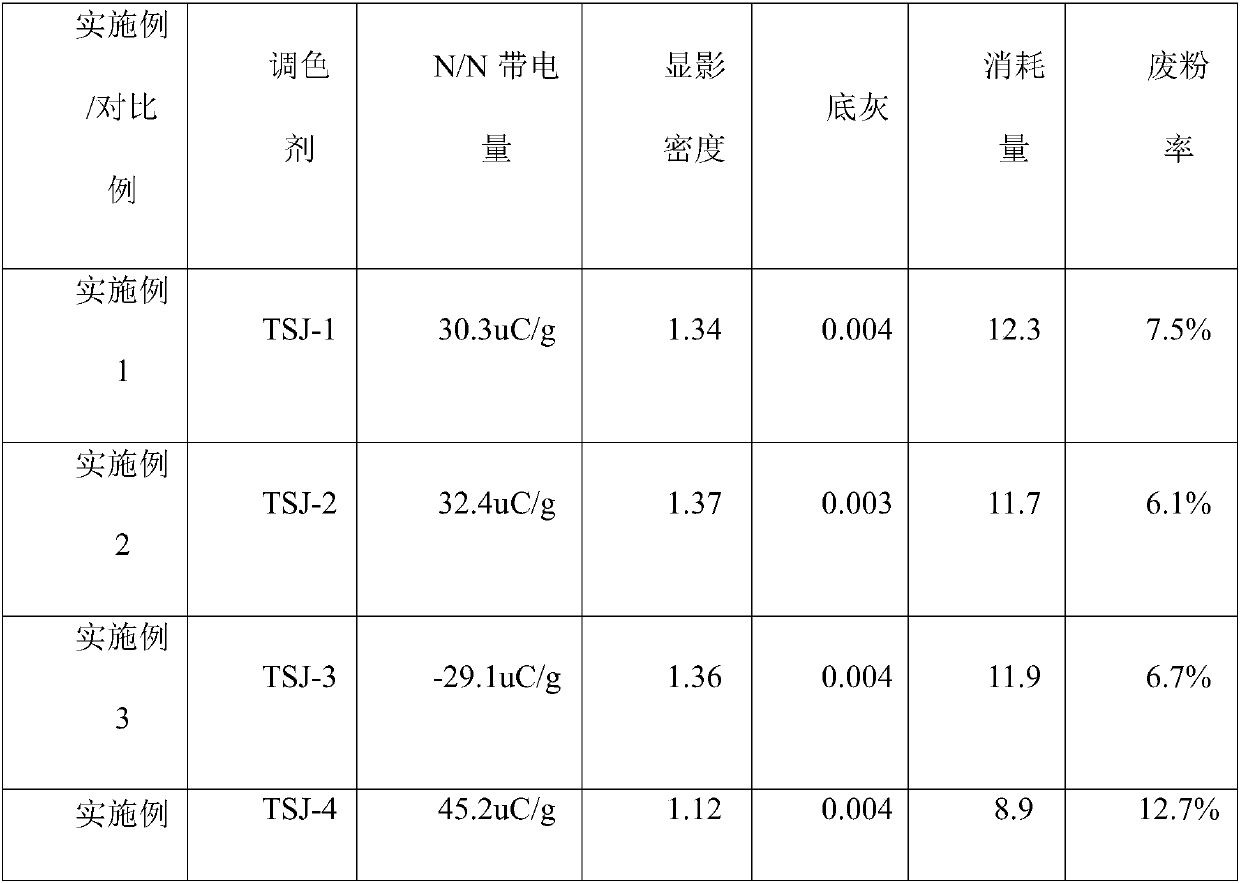

Embodiment 1

[0063] This embodiment provides a new type of toner MT-2 (i.e. charge regulator spray toner, containing 0.1% charge regulator), which is prepared by using the above components according to the following steps:

[0064] Weigh 100g of toner matrix particles MT-1 and 10g of charge regulator solvent dispersion E1, and spray them onto the surface of the toner matrix particles under the action of micro flash drying equipment, fluidized bed, etc., and the spraying process is at 50-140°C It is carried out at high temperature to form a dry granular material, which is then prepared by removing a good solvent to obtain a new toner MT-2.

Embodiment 2

[0066] This embodiment provides a new type of toner MT-3 (i.e. charge regulator spray toner, containing 1% charge regulator), which is prepared by using the above components according to the following steps:

[0067] Weigh 100g of toner matrix particles MT-1 and 10g of charge regulator solvent dispersion E2, and spray them onto the surface of toner matrix particles under the action of micro flash drying equipment, fluidized bed, etc. It is carried out at high temperature to form a dry granular material, which is then prepared by removing the good solvent to obtain a new toner MT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com