Electrical control system of aluminum alloy pelletizing shaft furnace

An electrical control system and control system technology, applied in the direction of electrical program control, general control system, control/adjustment system, etc., can solve the problems that cannot meet modern production, single data control communication network, lack of data acquisition function, etc., and achieve guidance The effect of energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

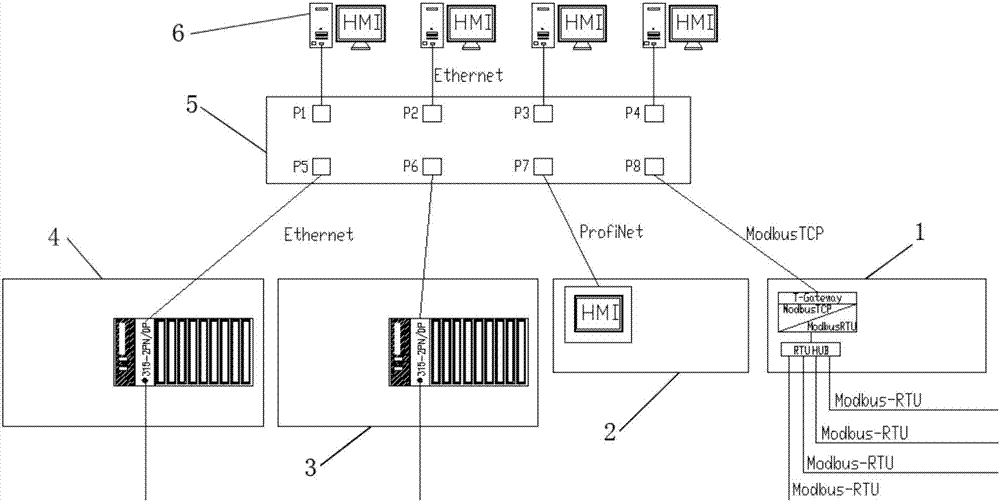

[0027] An electrical control system for a ferroalloy pellet shaft furnace, comprising an industrial computer group 6, an industrial switch 5, a public auxiliary system 4, a shaft furnace body control system 3, an on-site industrial computer 2, and a power detection and measurement system 1, the industrial computer group 6 Connected with the industrial switch 5, the industrial switch 5 is respectively connected with the public auxiliary system 4, the shaft furnace body control system 3, the field industrial computer 2 and the electric power detection and measurement system 1;

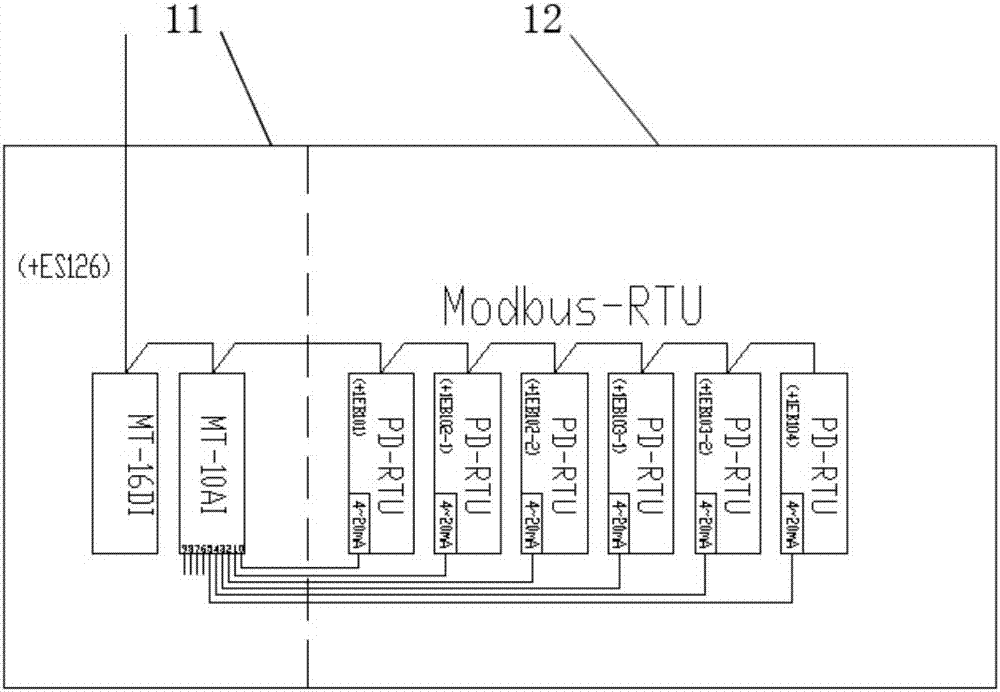

[0028] The power detection and metering system 1 includes an electric energy metering device 11 and a Modbus-RTU protocol interface 12 connected to each other, and the electric energy metering device 11 communicates with an on-site smart meter 18 through the Modbus-RTU protocol interface 12;

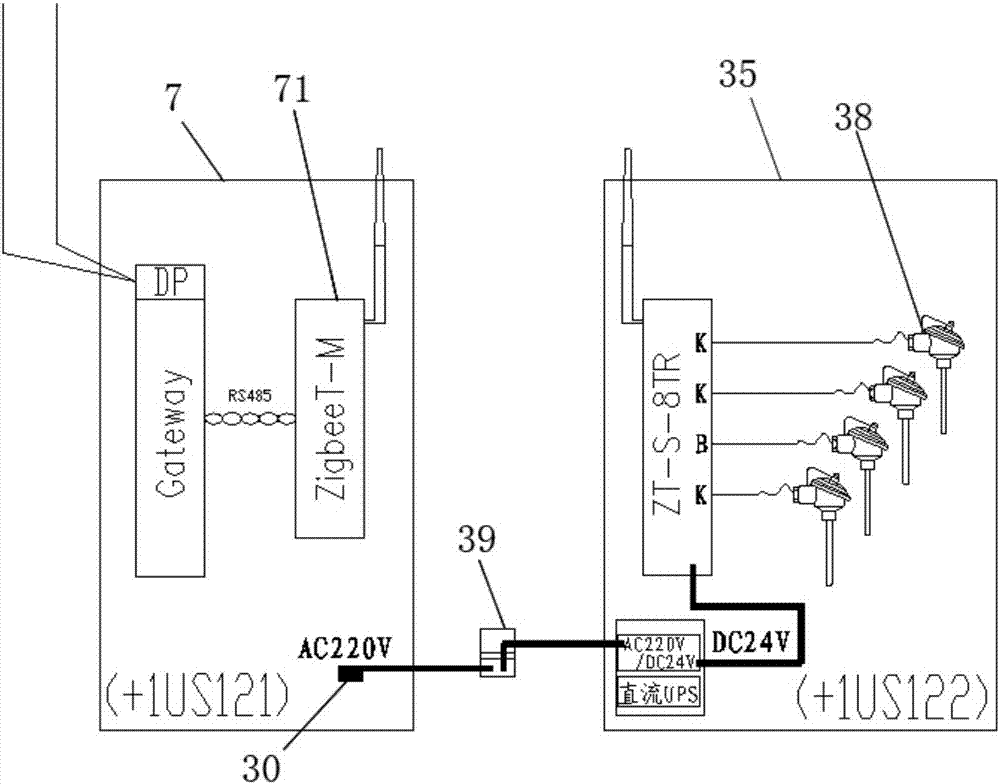

[0029] The shaft furnace body control system 3 includes a shaft furnace body industrial computer 31, which is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com