Receiver and assembly process thereof

A receiver and installation cavity technology, applied in the field of receivers, can solve the problems of inability to realize modularization and complicated installation process, and achieve the effects of improving sound quality, increasing electromagnetic driving force, and changing frequency response frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

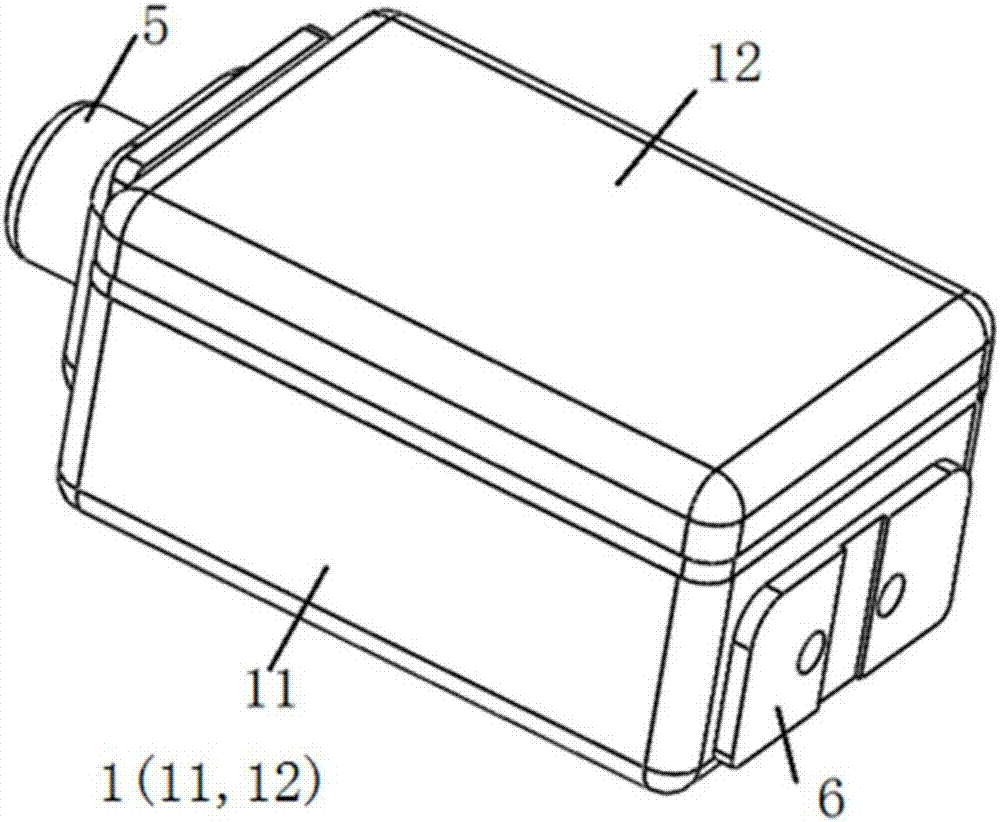

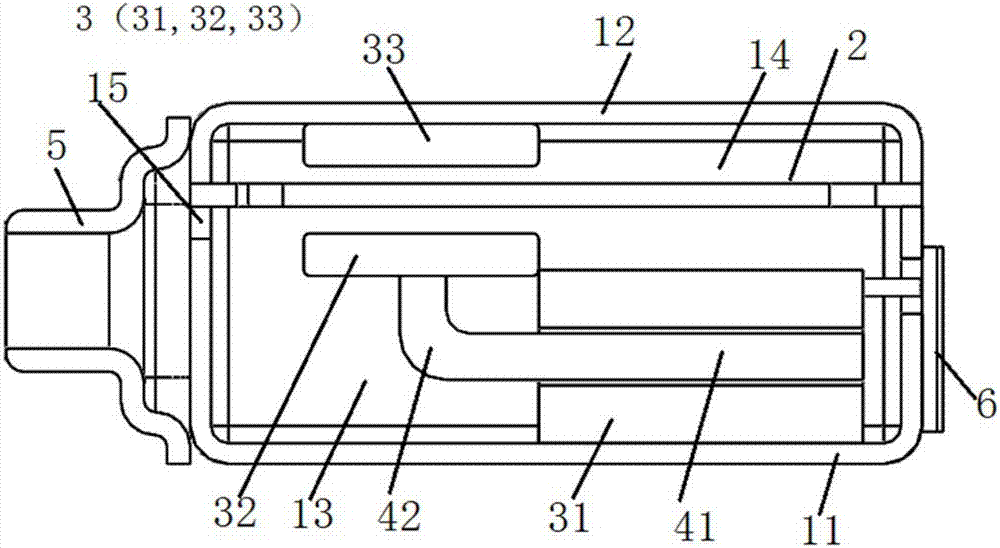

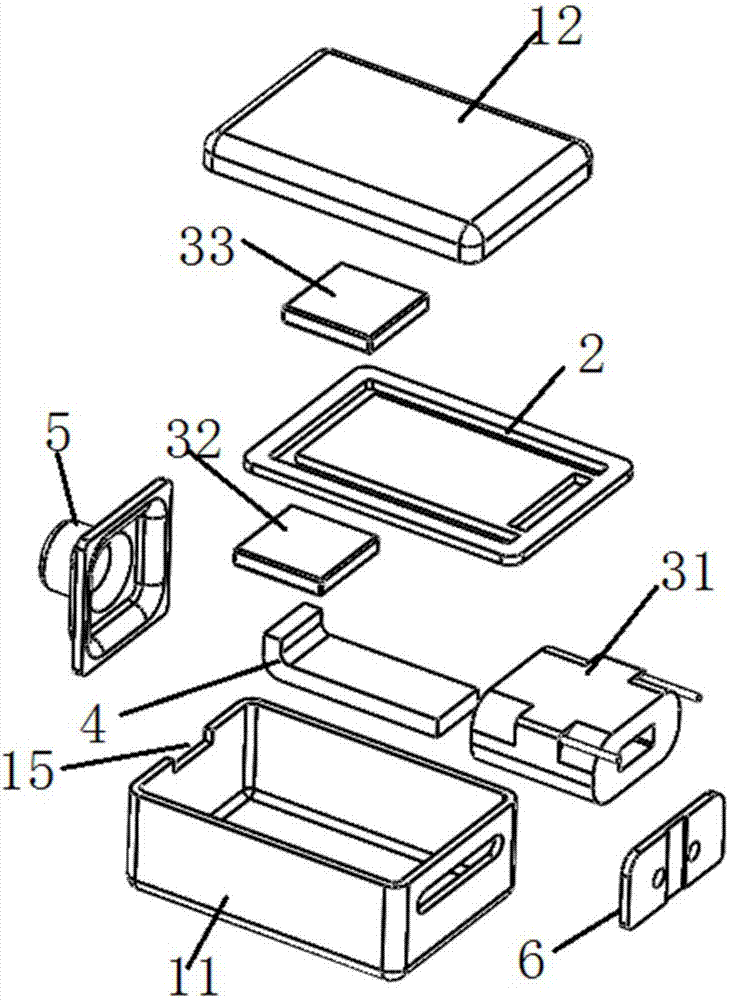

[0071] This embodiment provides a receiver, such as Figure 1 to Figure 3 As shown, it includes a casing 1 , a diaphragm mechanism 2 , an electromagnetic drive mechanism 3 , a welding pad 6 and a sound outlet tube 5 .

[0072] Such as figure 2 As shown, the shell 1 has a first shell 11 made of a first bottom surface and a side wall, and a second shell 12 made of a second bottom surface and a side wall; the second shell 12 is detachably connected to the first shell 11 buckle and encircle the inner cavity. The diaphragm mechanism 2 is arranged on the mouth edge (the edge of the opening) of the first housing 11 and the second housing 12, and divides the inner cavity of the housing 1 into an installation cavity 13 close to the first bottom surface and a second housing close to the bottom surface. Sound cavity 14 on the bottom surface. Correspondingly, the inner cavity of the first housing 11 forms the installation cavity 13 , and the inner cavity of the second housing 12 forms...

Embodiment 2

[0104] This embodiment provides an assembly process of a receiver, which includes a first shell 1, a second shell 1, a first coil, a second coil, a diaphragm mechanism 2, two conversion parts 4, a first magnet 32 and a second magnet 33 . The specific steps of the assembly process are:

[0105] S1: Install the straight part 41 of the conversion element 4 in the first coil in advance, and then arrange the first coil on the inner wall surface of the first housing 11 parallel to the diaphragm mechanism 2, for example, the first coil of the first housing 11 A bottom surface, and then the first magnet 32 is fixed on the bending part 42 of the conversion part 4 to form the first module;

[0106] S2: Pre-install the straight part 41 of another conversion element 4 in the second coil, and then arrange the second coil parallel to the diaphragm mechanism 2 on the inner wall surface of the second housing 12, such as the second housing 12 On the second bottom surface of the second ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com