A kind of tunnel waterproof board laying method

A technology of tunnel waterproofing board and laying method, applied in tunnels, tunnel linings, mining equipment and other directions, can solve the problems of easy falling off, weak welding, easy scalding, etc., and achieves low welding temperature requirements, short welding time, and control damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

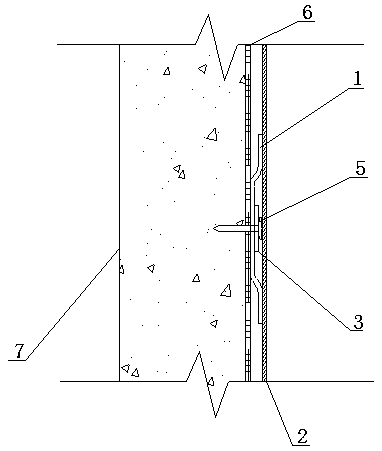

[0022] see Figure 1 to Figure 3 , a method for laying a tunnel waterproof board, relates to a tunnel waterproof construction process, comprising the following steps:

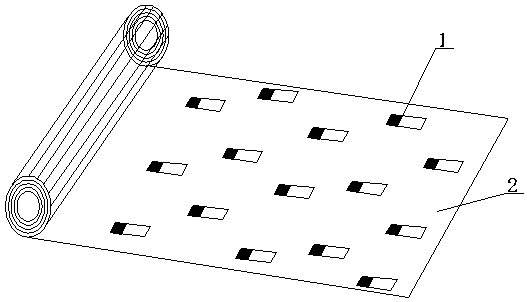

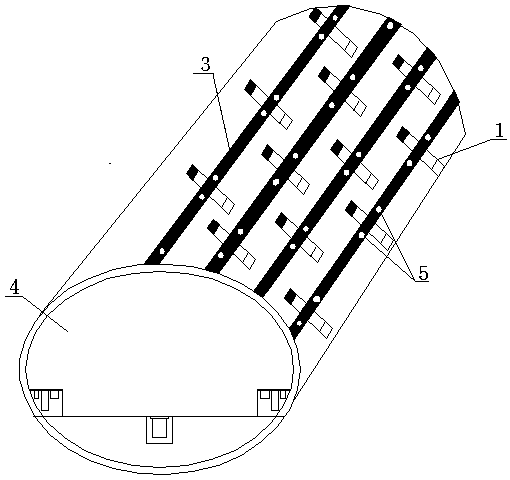

[0023] Step 1: Cut out the strip 1 with the number of hot-melt gaskets required by the design, and use the strip 1 to replace the hot-melt gasket. Outside the site, the strip 1 is first arranged on the waterproof board 2 to be laid in a plum blossom shape according to the design requirements for the spacing of the hot-melt gaskets. Since the waterproof board 2 is spread in the tunnel 4 in a circular direction, the short edge of the strip 1 The longitudinal section and long side of the tunnel 4 are arranged along the direction of the cross section of the tunnel 4; then, one end of the strip 1 is thermally welded to the waterproof board 2 to be laid with a hot blower ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com