Directional valve with check valve function

A directional valve and check valve technology, applied in the direction of functional valve type, valve operation/release device, lift valve, etc., can solve the problems of difficult closing of the plunger, high beam speed, etc., and achieve the effect of complete opening and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

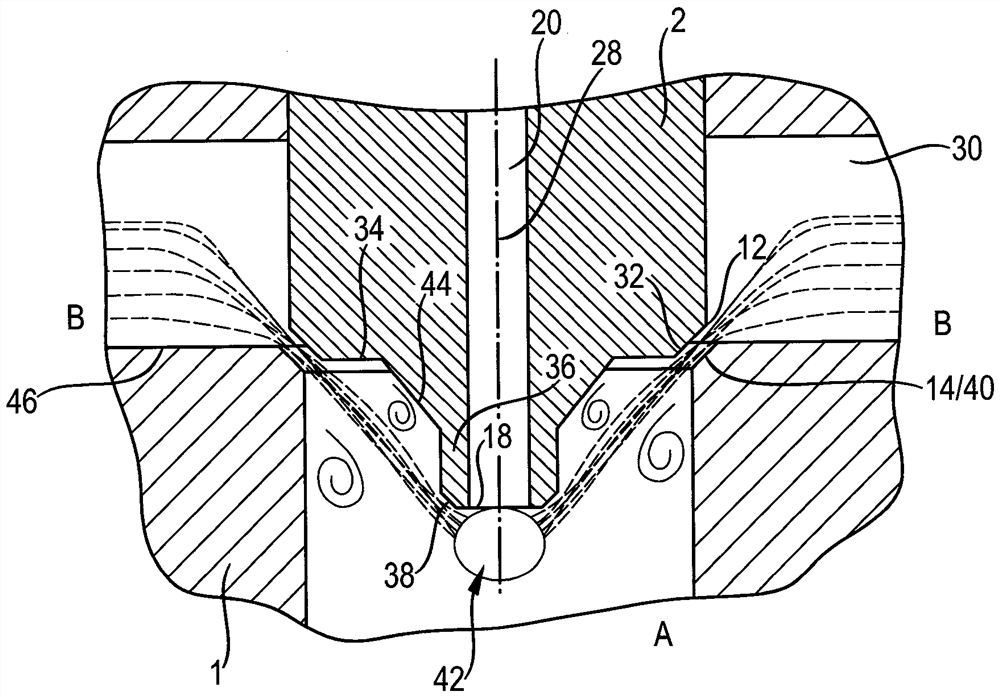

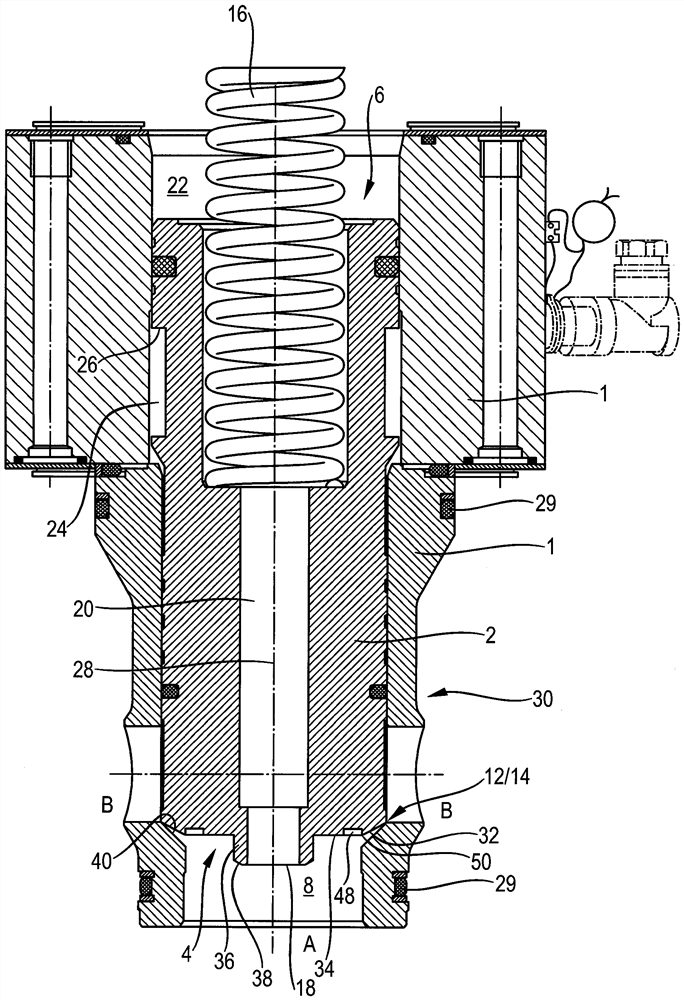

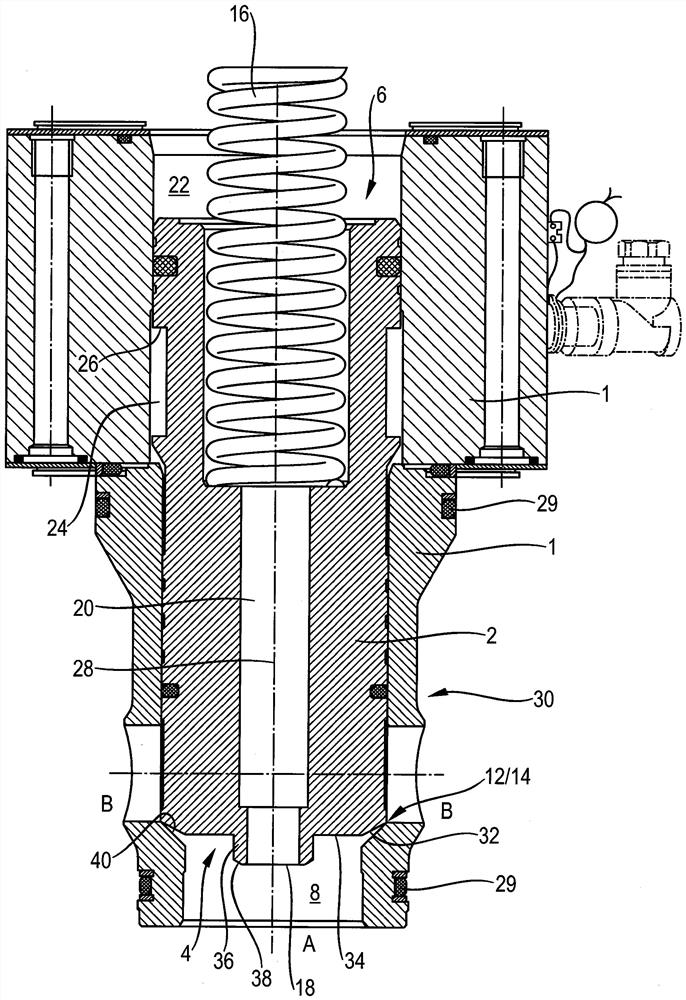

[0032] figure 1A first exemplary embodiment of a directional valve according to the invention is shown, which is designed as an active logic valve. It has a two-component valve housing 1 in which a stepped plunger 2 is guided. The plunger 2 has a first end side 4 and a second end side 6 opposite the first end side. In the region of the first end side 4 there is an outlet-side pressure chamber 8 which communicates with the outlet port A, while an inlet port B formed by radial bores is arranged on the outer circumference of the plunger 2 .

[0033] In active logic valve's or plunger 2's figure 1 In the closed position shown in , the edge 12 of the first end side 4 of the plunger 2 presses into the housing-side valve seat 14 . To this end, the force of a spring 16 acts, which is partially inserted into the second end side 6 of the plunger 2 and which bears against a section (not shown) of the valve housing 1 . Furthermore, the pressure of the outlet connection A acts in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com