Electro-mechanical dual control pilot valve for unloading valve

An electromagnetic pilot valve and pilot valve technology are applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., which can solve the problems of increased manufacturing cost, difficult manufacturing, inconvenient maintenance, etc., to reduce the overall size, reduce Effects that are difficult to manufacture and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

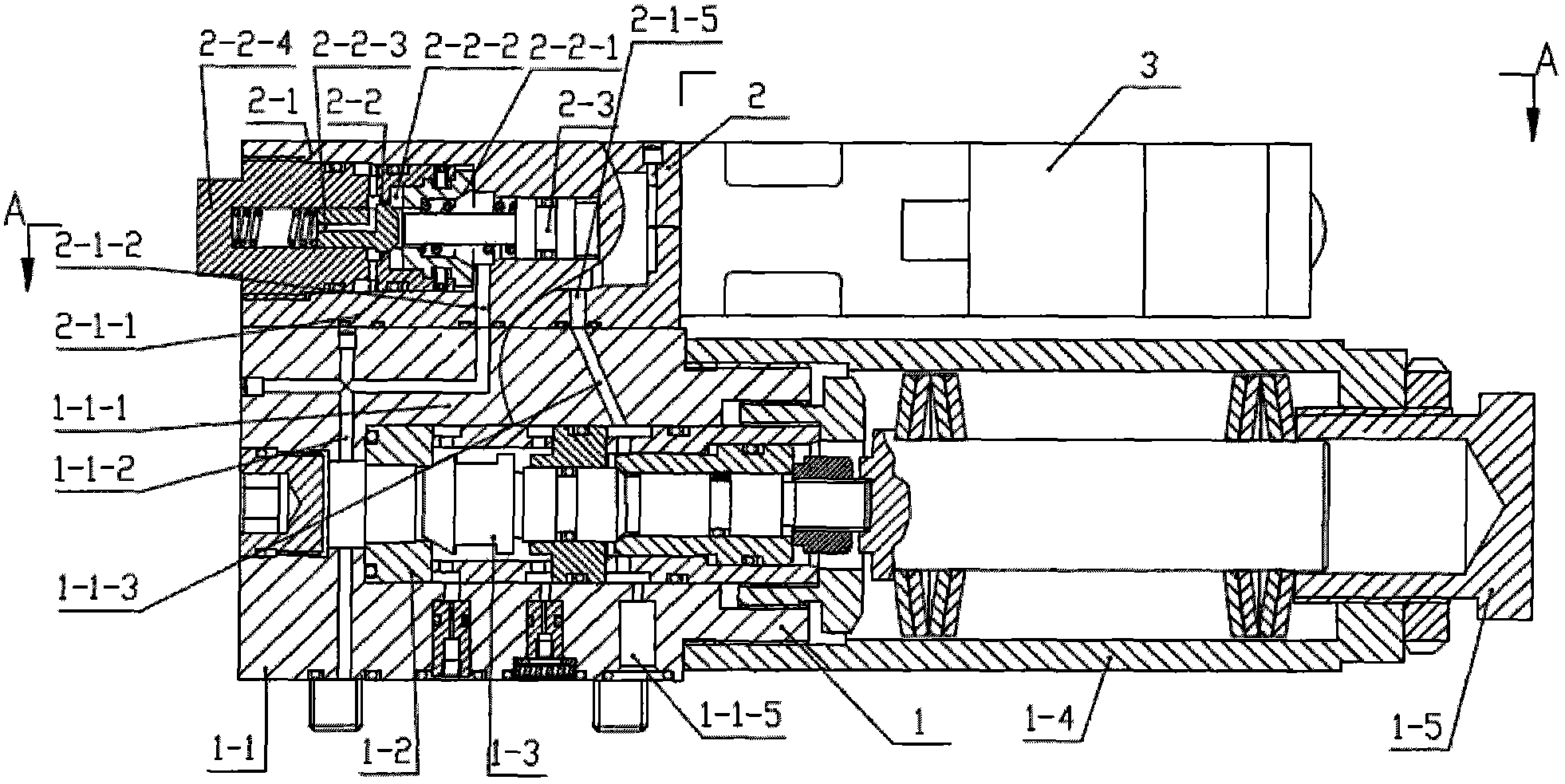

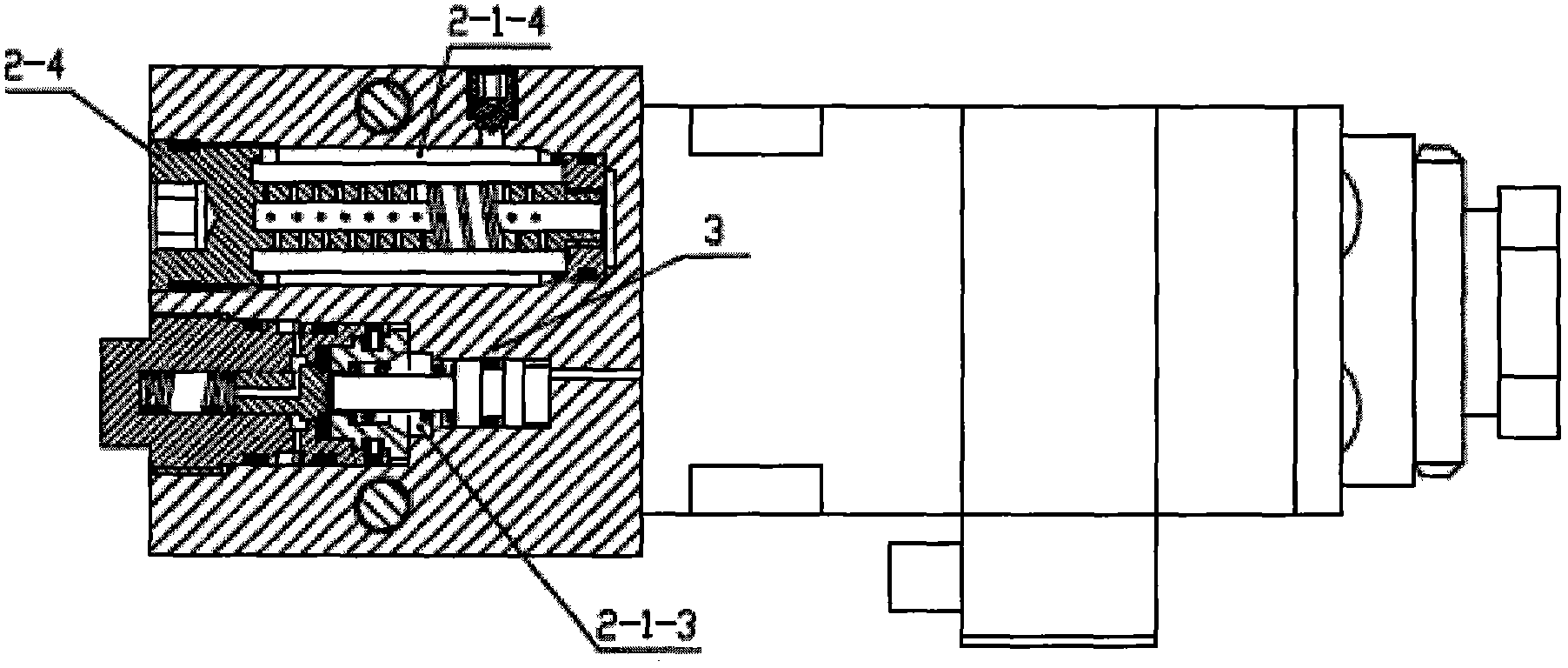

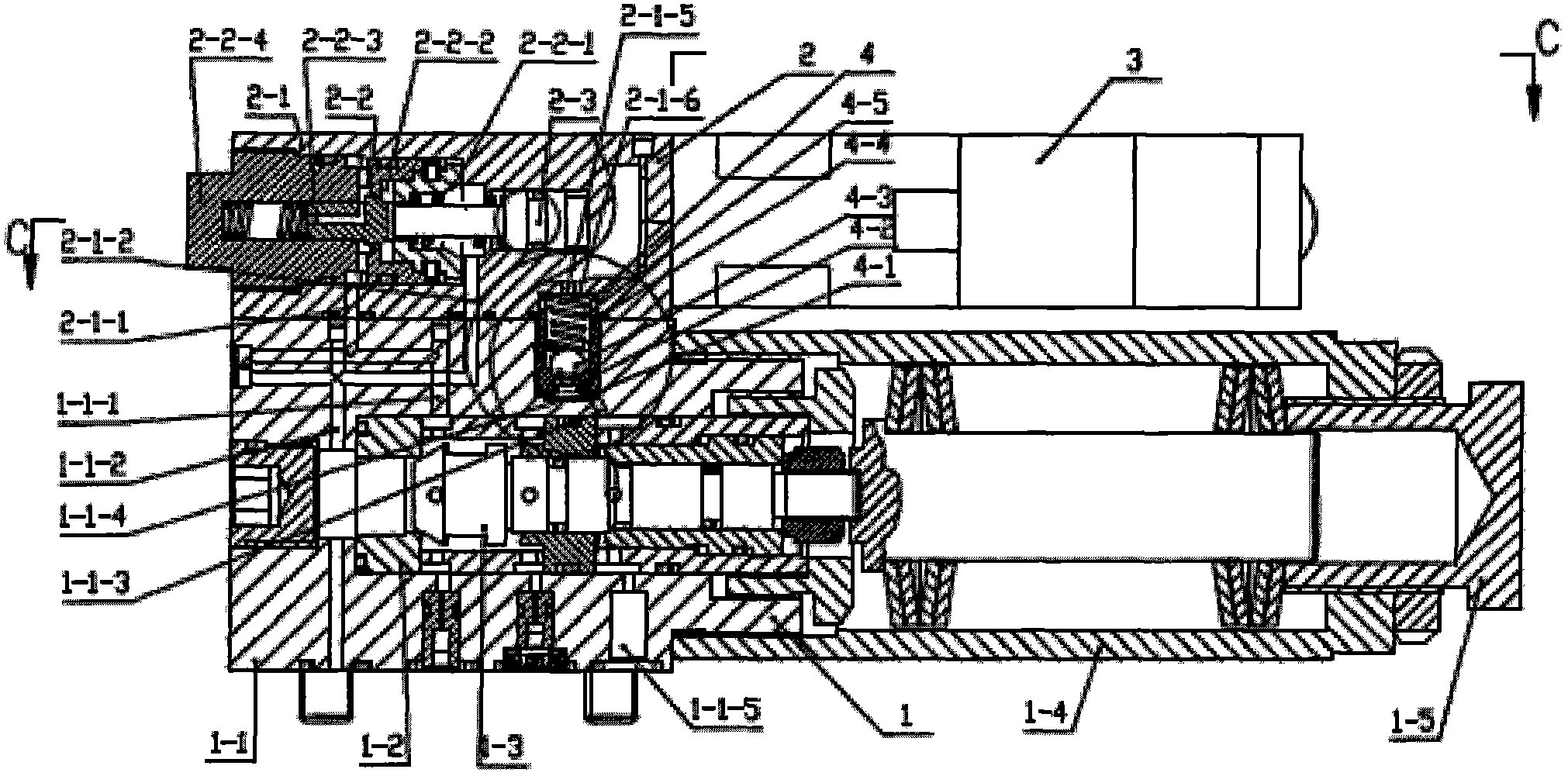

[0046] As shown in the accompanying drawings, the present invention includes a mechanical pilot valve 1, an auxiliary valve 2 that functions as an electronically controlled bypass switch valve, and an electromagnetic pilot valve 3. The auxiliary valve 2 is installed on the back of the mechanical pilot valve 1; The valve 3 is installed on the auxiliary valve 2. The mechanical pilot valve 1 includes a valve body 1-1, a valve seat 1-2, a valve core 1-3, a spring sleeve 1-4 and a pressure regulating screw 1-5. The valve body 1-1 is processed with a valve body first liquid channel 1-1-1 communicating with a process hole, a valve body second liquid channel 1-1-2 communicating with a process hole, and an incoming liquid port 1-1. -5 communicated valve body communication hole 1-1-3; the auxiliary valve 2 includes an auxiliary valve body 2-1, a cartridge valve core 2-2 and an auxiliary valve ejector rod 2-3, and the auxiliary valve body 2-1 The first liquid passage 2-1-1 and the auxili...

specific Embodiment approach 2

[0047] On the basis of Embodiment 1, the filter element 2-4 installed in the second main hole 2-1-4 of the auxiliary valve body is replaced with the filter element 2-5 containing the accumulator quick connector seat 2-5-1.

specific Embodiment approach 3

[0048]On the basis of specific embodiment 1 or specific embodiment 2, a valve body counterbore 1-1-4 communicating with the valve body communication hole 1-1-3 is processed on the valve body 1-1. The auxiliary valve body 2-1 is processed with an auxiliary valve body counterbore 2-1-6 communicated with the auxiliary valve body communication hole 2-1-5, and the auxiliary valve body sink hole 1-1-3 and the auxiliary valve body sink The holes 2-1-6 form the inner cavity of the one-way valve, and the one-way valve assembly 4 is installed in the inner cavity of the one-way valve, and the one-way valve assembly 4 includes a limit piece 4-1, a one-way valve seat 4-2 , steel ball 4-3, connection sleeve 4-4 and spring 4-5.

[0049] The high-pressure liquid enters the communication hole 1-1-3 of the valve body through the incoming liquid port 1-1-5, then enters the communication hole 2-1-5 of the auxiliary valve body, and then enters the second main hole 2-1-4 of the auxiliary valve body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com