Food contact sheet specific migration test sampling soaking device

A food contact and sheet technology, which is applied in the field of devices for soaking food contact sheets, can solve the problems of inaccurate detection results, high content of toxic and harmful substances, distortion, etc., and achieve accurate detection and no interference of migration on the cut surface of the sheet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

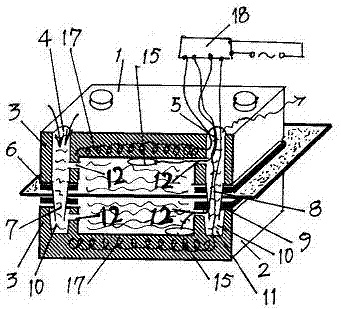

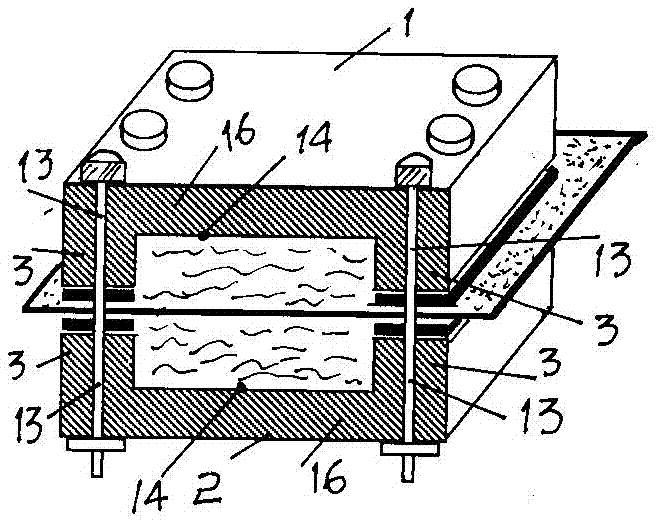

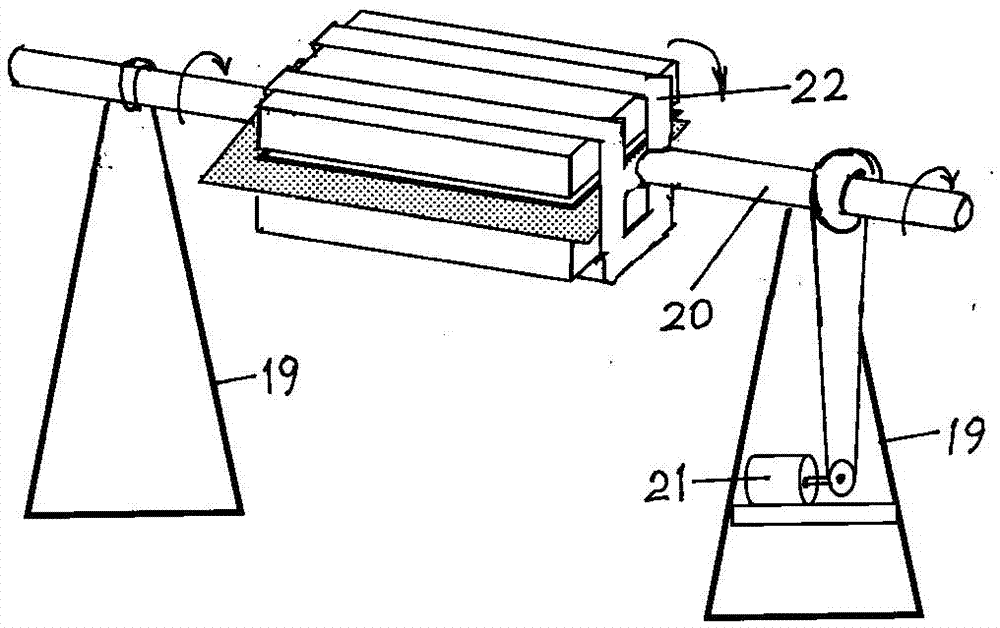

[0025] Example 1, Sampling and Soaking Device for Specific Migration Test of Food Contact Sheets

[0026] Such as figure 1 , 2 3. Sampling and soaking device for the specific migration test of food contact sheets, including two glass upper covers 1 and glass lower covers 2 with the same size and shape of the outer shape and the same size and shape of the inner hollow depression; the upper cover 1 and the lower cover 2 The thickness of the side wall 3 is the same, and the thickness of the side wall 3 is 2 cm;

[0027] In different positions of the side wall 3 of the upper cover 1, there are liquid inlet holes 4 and air outlet holes 5; on the side wall end face 6 of the upper cover opening, the liquid inlet hole 4 is connected with a tapered liquid outlet pipe 7; The side wall end surface 6 and the air outlet hole 5 are connected with a tapered air outlet pipe 8; the liquid inlet hole 4 and the air outlet hole 5 communicate with the inner space of the upper cover 1 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com