Method and device for measuring mechanical parameters of double-layer double-clamped beam

A technology of mechanical parameters and measurement methods, which is applied to the measurement of mechanical parameters of double-end fixed beams and the field of mechanical parameter measurement of double-layer double-ended fixed beams. It can solve problems such as large test errors and achieve good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

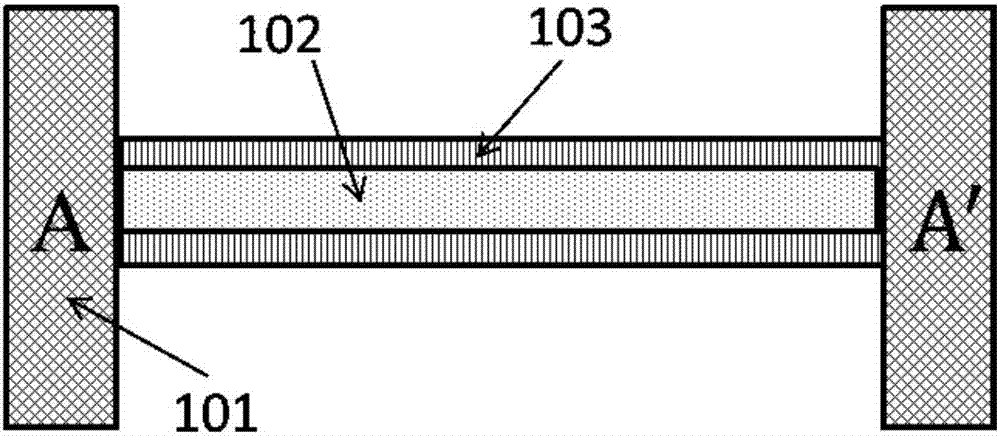

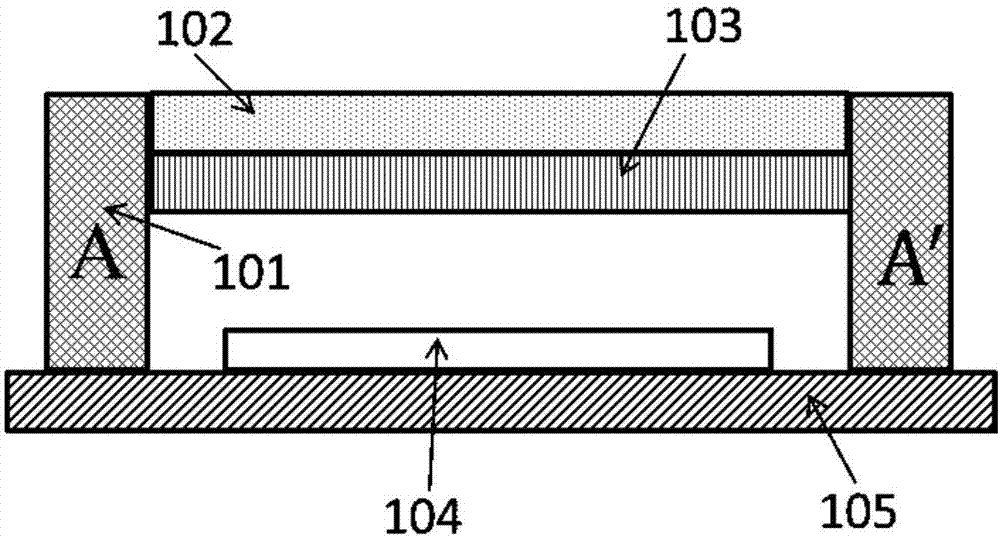

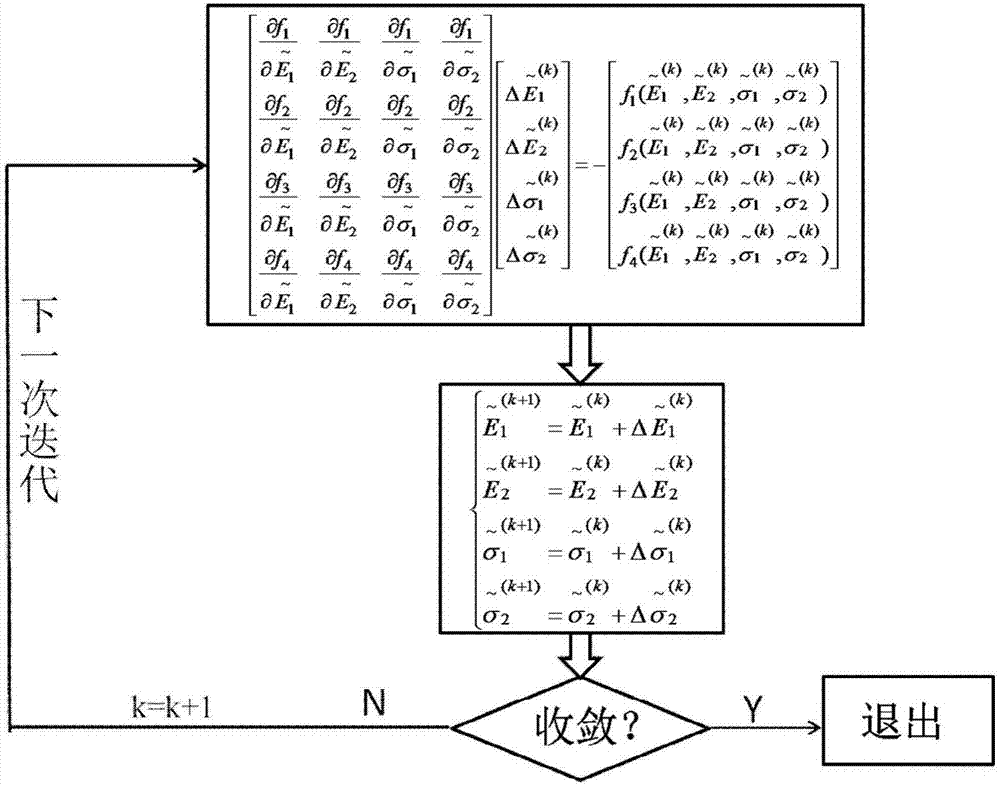

[0031] In order to facilitate the public's understanding, firstly, a brief introduction is given to the construction process of the pull-in voltage analytical model of the double-layer double-ended fixed-supported beam in the technical solution of the present invention:

[0032] suppose represent the equivalent Young’s modulus of the upper and lower layers of double-layer double-end fixed beams with unequal widths, respectively, represent the equivalent residual stresses of the upper and lower floors of double-layer double-end fixed-supported beams with unequal widths, respectively, w 1 、w 2Respectively represent the width of the upper and lower floors of the unequal-width double-layer fixed-end beam, l is the length of the unequal-width double-layer double-end fixed beam, h is the single-layer thickness of the unequal-width double-layer double-end fixed beam.

[0033] For double-layer double-end fixed-support beams, when the width and thickness of the film satisfy b i i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com